Slag cooling device applicable to dry slag discharge machines and application thereof

A dry-type slag discharger and slag cooling technology are applied in the field of electric power equipment to achieve the effect of strengthening the cooling effect and improving the economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

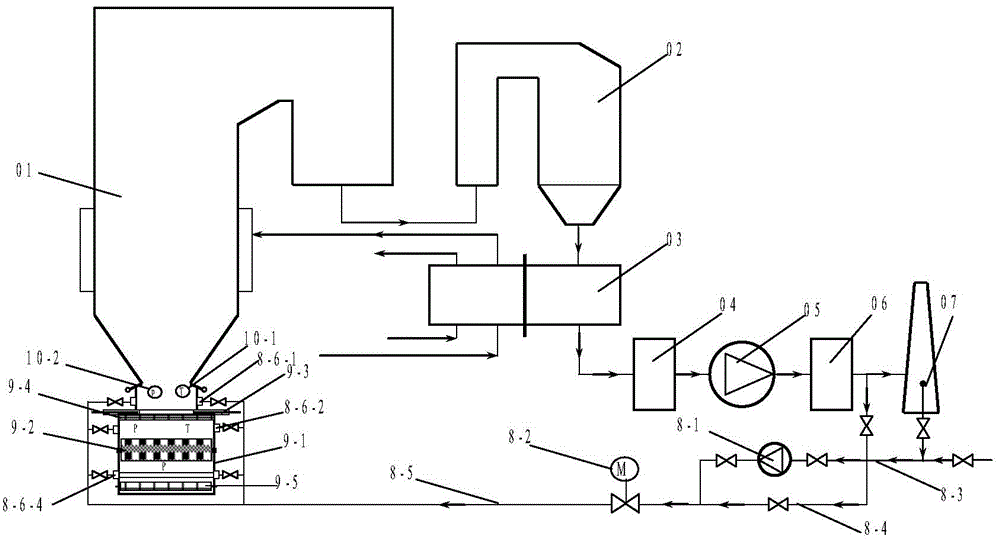

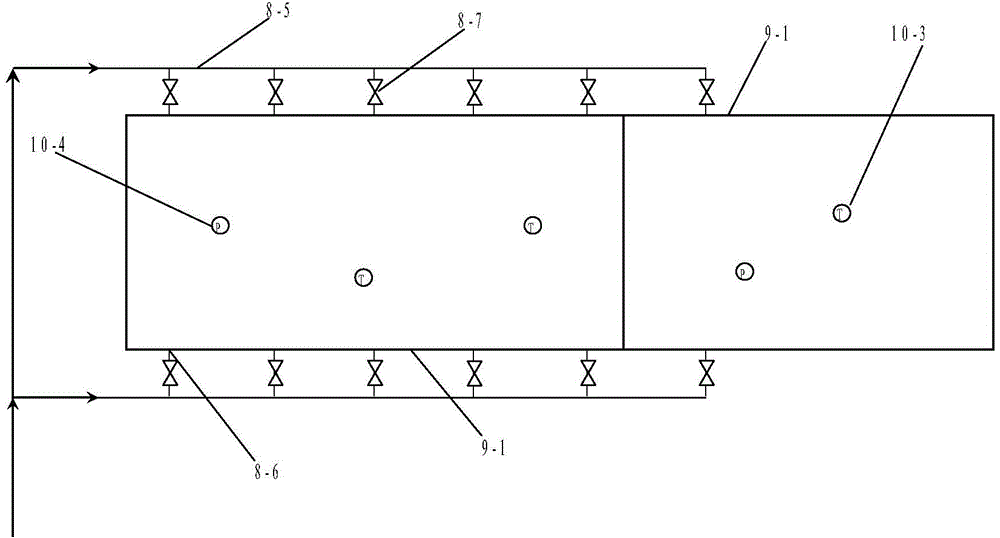

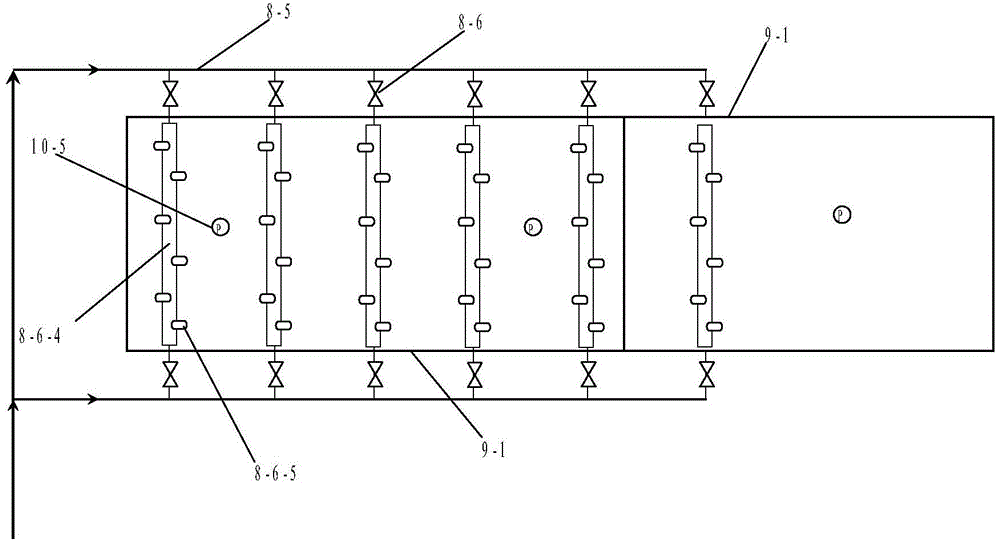

[0025] Dry slag dischargers including slag cooling, see Figures 1 to 4 , including dry slag machine body 9, cooling device 8 and control system 10.

[0026] The body 9 of the dry slag discharger includes a housing 9-1 and a shut-off door 9-3, a grill 9-4, a conveyor belt 9-2 and a cleaning chain 9 arranged in the housing 9-1 from top to bottom. -5;

[0027] The cooling device 8 includes a clean flue gas flow regulating valve 8-2, a clean flue gas temperature adjustment bypass 8-3, a clean flue gas fan bypass 8-4, a set of low-temperature clean flue gas nozzles 8-6, and net flue gas outlets connected in sequence. Flue gas fan 8-1, low-temperature clean flue gas pipeline 8-5, clean flue gas used for cooling slag is extracted from the flue at the outlet of desulfurization tower 6 by clean flue gas fan 8-1, a group of low-temperature clean flue gas nozzles 8-6 They are respectively connected to the low-temperature clean flue gas pipeline 8-5 through the valve 8-7, the clean flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com