Vertical parallelometer

A technology of collimator and vertical part, which is applied in the field of vertical collimator, can solve the problems of obsolete functions and reduced use value, and achieve the effects of small environmental factors, strong stability, and simple and convenient installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

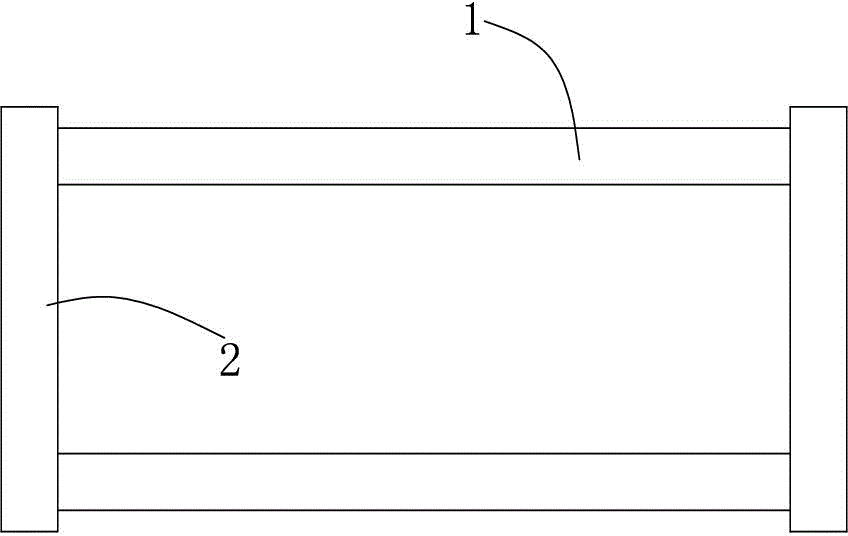

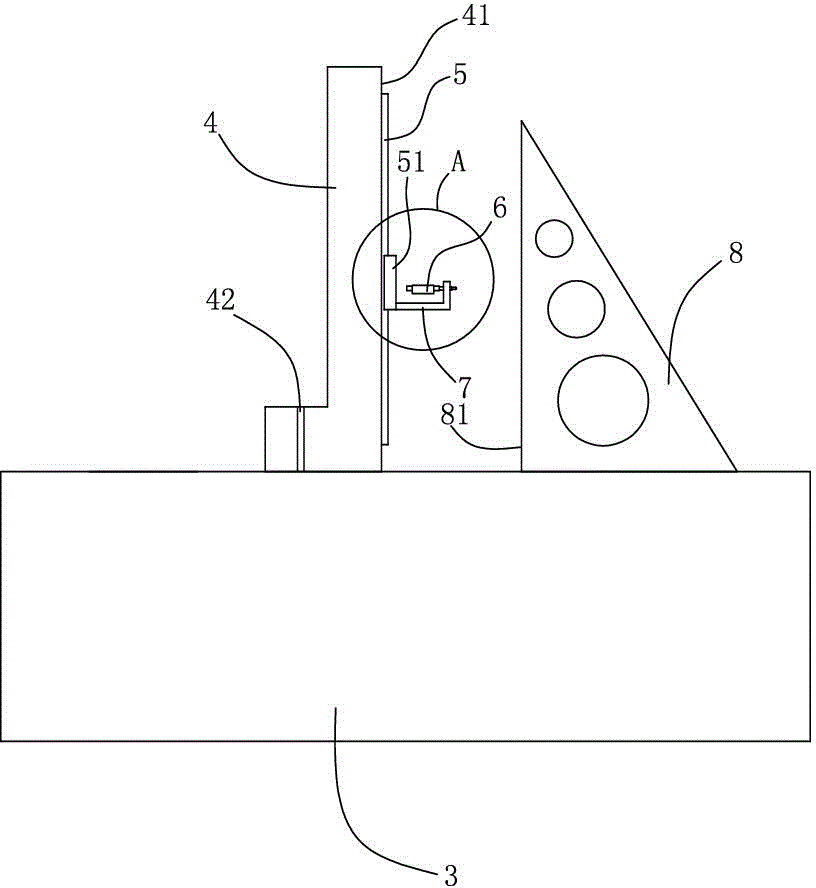

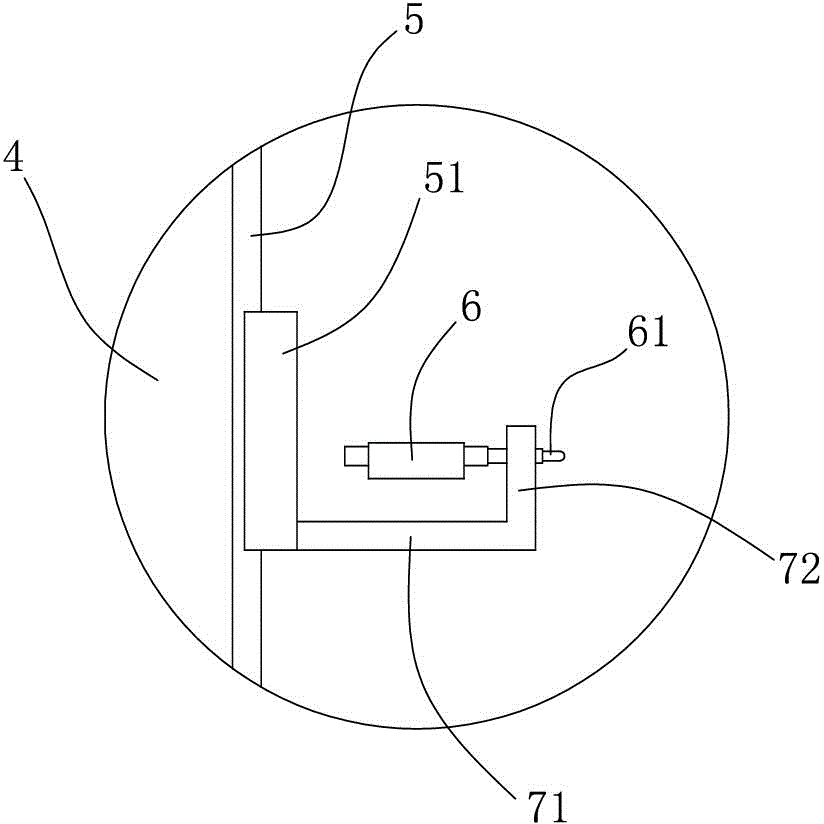

[0021] Example: such as figure 2 with image 3 Shown, a kind of vertical parallel instrument of the present invention comprises marble platform 3, is provided with an L-shaped marble substrate 4 movably on described marble platform 3, on the side perpendicular to marble platform 3 of this L-shaped marble substrate 4 41 is vertically provided with a guide rail 5, on which a dial gauge 6 can be moved up and down. The side 41 of 4 is vertical and faces away from this side 41.

[0022] The bottom surface of the L-shaped marble base 4 is provided with blowing grooves, and the L-shaped marble base 4 is provided with blowing holes 42 communicating with the blowing grooves.

[0023] The blow hole 42 is connected with an air pump.

[0024] A slide block 51 is arranged on the guide rail 5 , and a watch base 7 is fixed on the slide block 51 , and the dial indicator 6 is arranged on the watch base 7 .

[0025] It also includes a marble square 8 , which is movably arranged on the marb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com