A metal grid frequency selective surface structure and its manufacturing method

A frequency selective surface and metal grid technology, applied in the field of optical windows, can solve the problems of reducing the light transmission performance, reducing the light transmission performance and electromagnetic shielding performance of the frequency selective surface structure of the metal grid, and uneven distribution of high-order diffraction energy. , to achieve the effect of improving light transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0051] This embodiment is an embodiment of a metal grid frequency selective surface structure.

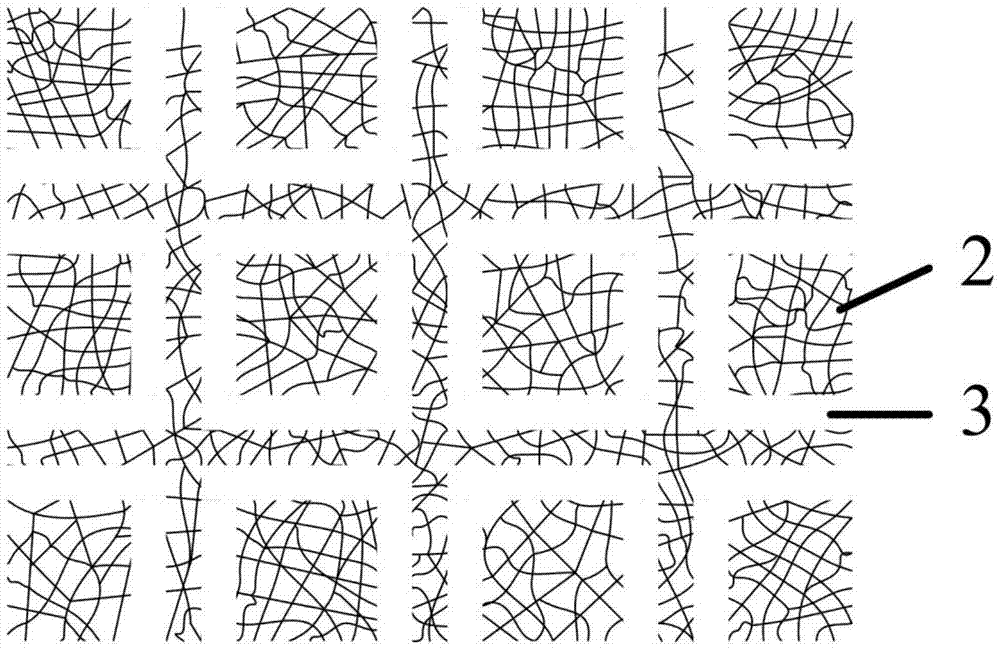

[0052] The frequency-selective surface structure of the metal grid of this embodiment includes a substrate 1, a transparent grid film 2 distributed on the substrate 1, and the surface of the transparent grid film 2 has a periodic opening array 3;

[0053] The shape of the transparent grid film 2 is a pattern formed by natural drying of the cracked nail polish containing acrylic resin at a temperature of 20-25°C and a humidity of 50-80%RH;

[0054] The inside of the periodic opening array 3 has one of the following two structures:

[0055] Structure 1. No transparent mesh film 2;

[0056] Structure 2: Containing a transparent mesh film 2, the transparent mesh film 2 inside the hole and the transparent mesh film 2 outside the hole are not connected.

[0057] Here, the periodic opening array 3 is a square ring, the periodic opening array 3 contains a transparent mesh film 2 inside, and the trans...

specific Embodiment 2

[0059] This embodiment is still an embodiment of the metal grid frequency selection surface structure.

[0060] The frequency selective surface structure of the metal grid of this embodiment includes a substrate 1, a transparent grid film 2 and a periodic opening array 3 distributed on the substrate 1; the transparent mesh film 2 and the periodic opening array 3 are The exchange of corresponding positions described in the first embodiment.

specific Embodiment 3

[0062] This embodiment is an embodiment of a method for manufacturing a frequency selective surface structure of a metal grid.

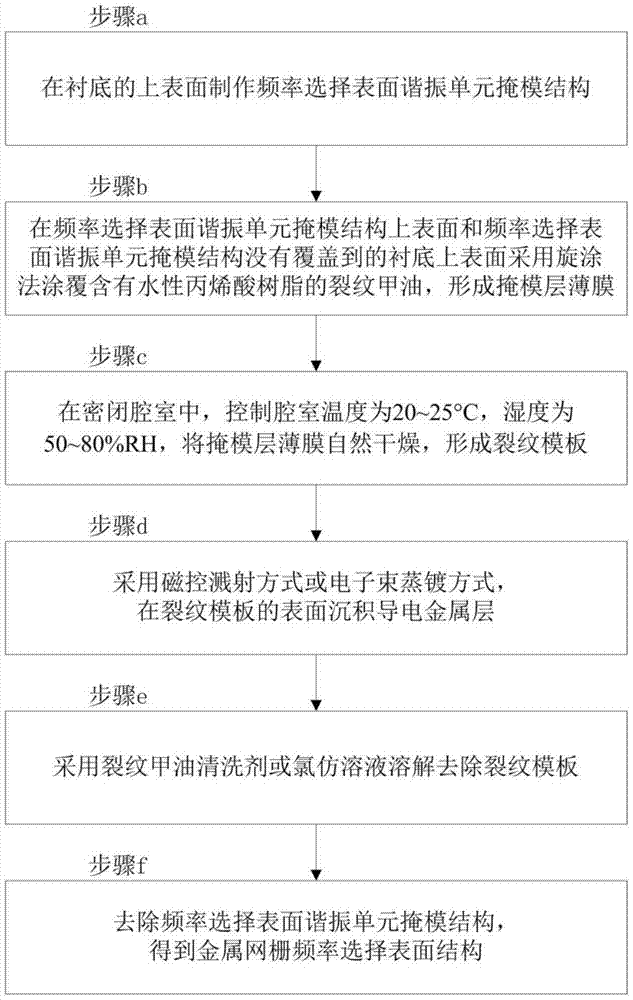

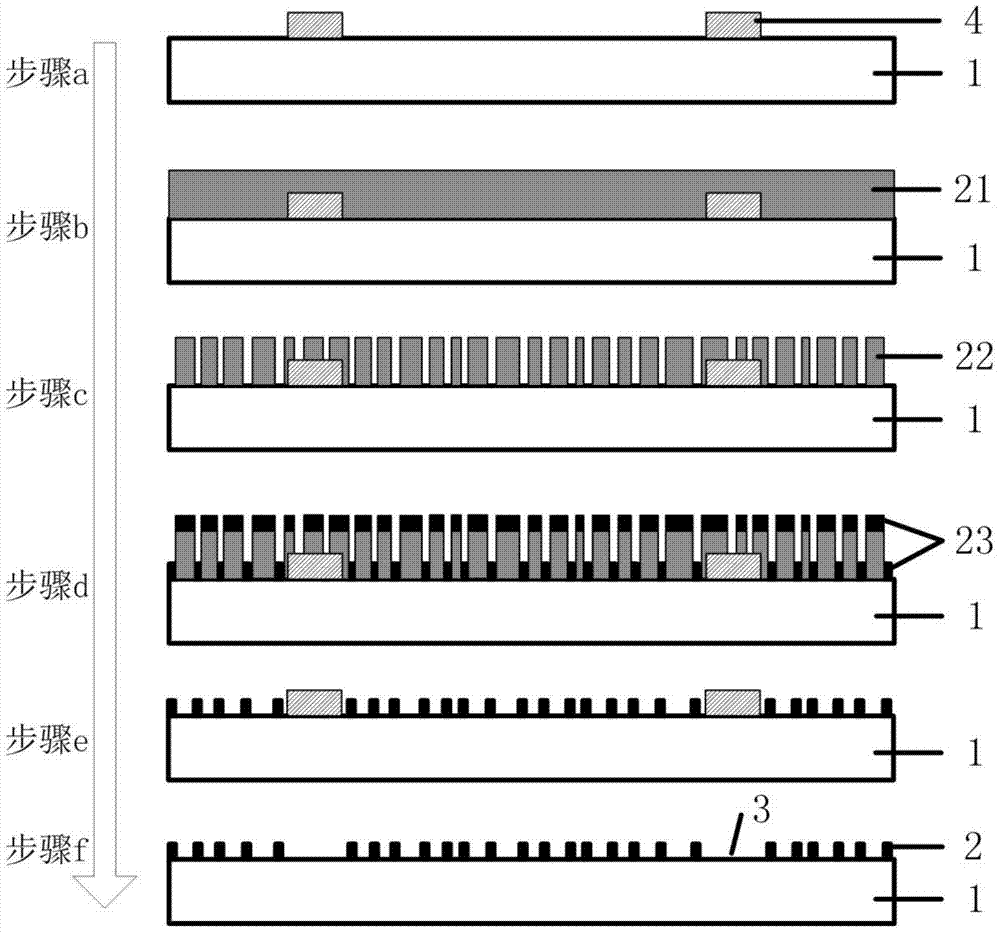

[0063] The manufacturing method of the frequency selective surface structure of the metal grid of this embodiment, the flowchart is as figure 2 Shown. The method includes the following steps:

[0064] Step a, fabricating a frequency selective surface resonance unit mask structure 4 on the upper surface of the substrate 1;

[0065] In step b, the upper surface of the frequency selective surface resonant unit mask structure 4 and the upper surface of the substrate 1 not covered by the frequency selective surface resonant unit mask structure 4 are coated with a crack nail polish containing water-based acrylic resin by a spin coating method to form Mask layer film 21;

[0066] Step c, in a closed chamber, the temperature of the chamber is controlled to be 20-25°C and the humidity is 50-80%RH, and the mask layer film 21 is naturally dried to form a crack templa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com