Arc extinguish chute, arc extinguish chamber and breaker

A technology of arc extinguishing grid and arc extinguishing chamber, which is applied in the direction of circuit breaker components, circuits, electrical components, etc., which can solve the problem that the circuit breaker cannot meet the arc extinguishing effect and arc ignition speed at the same time, so as to avoid blockage and avoid blockage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

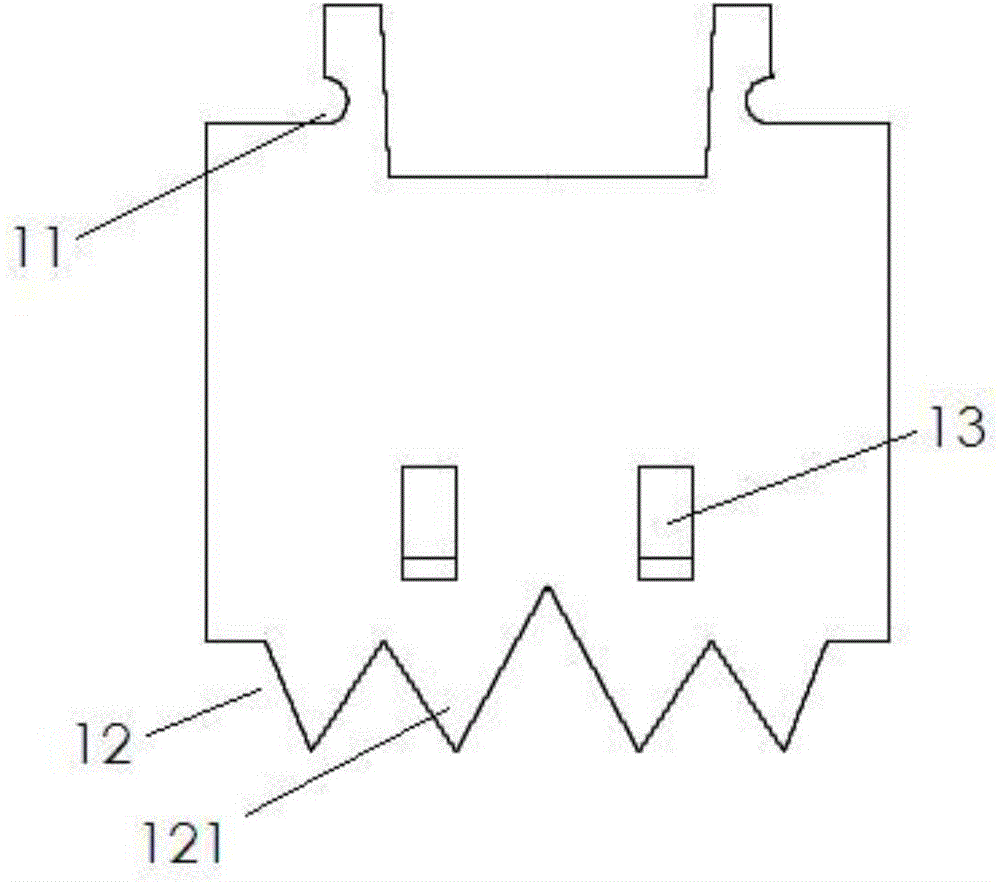

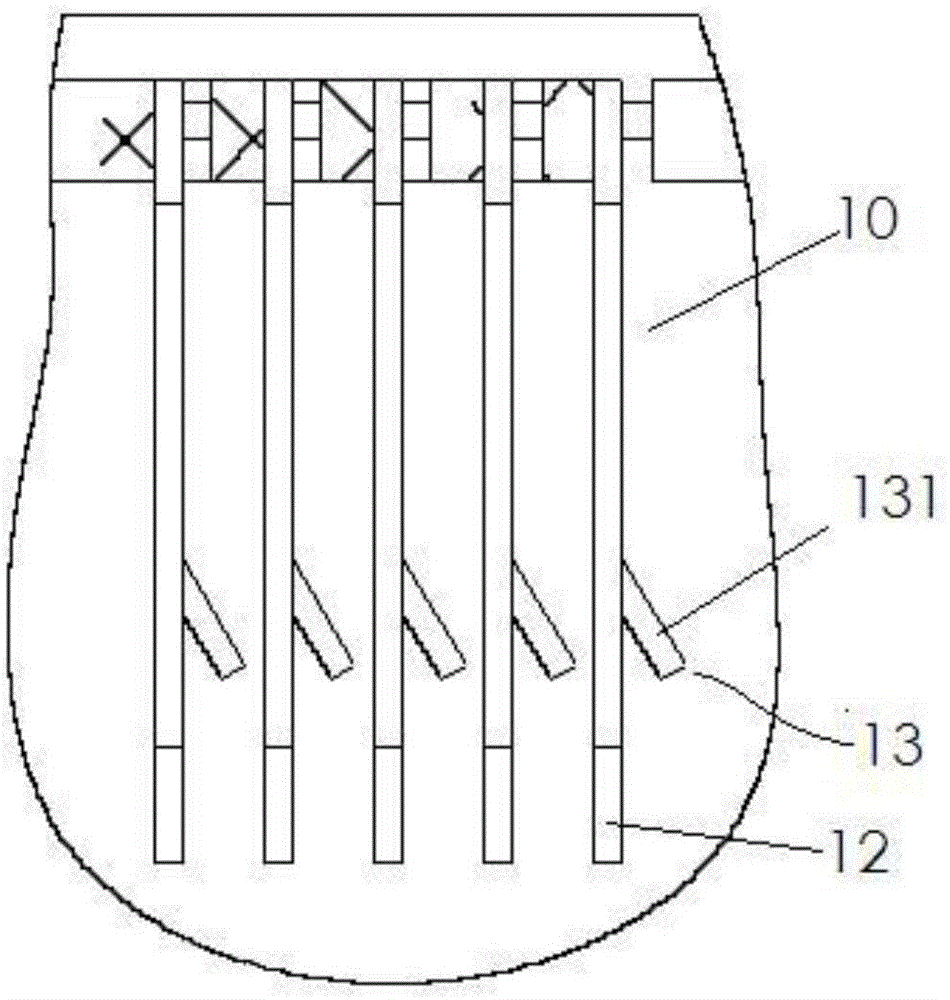

[0029] This embodiment provides an arc extinguishing grid, refer to figure 1 and figure 2 , the arc extinguishing grid includes a sheet-shaped grid body 10, in figure 1 In the state shown, the upper end of the grid body 10 is provided with a mounting part 11 for buckling or clamping, and the lower end of the grid body 10 is formed with an arc striking part 12 along the length direction. The grid body 10 is further formed with at least one protruding portion 13 protruding from the surface of the grid body 10 and obliquely disposed on the grid body 10 between the mounting portion 11 and the arc leading portion 12 .

[0030] refer to figure 2 The schematic diagram of the working state of the arc extinguishing grid in the arc extinguishing chamber is shown, when the arc is attracted to the arc through the arc strike plate 30 figure 2 When the leftmost grid body 10 shown is on the grid body 10, since the electrical distance between the protruding portion 13 and the adjacent g...

Embodiment 2

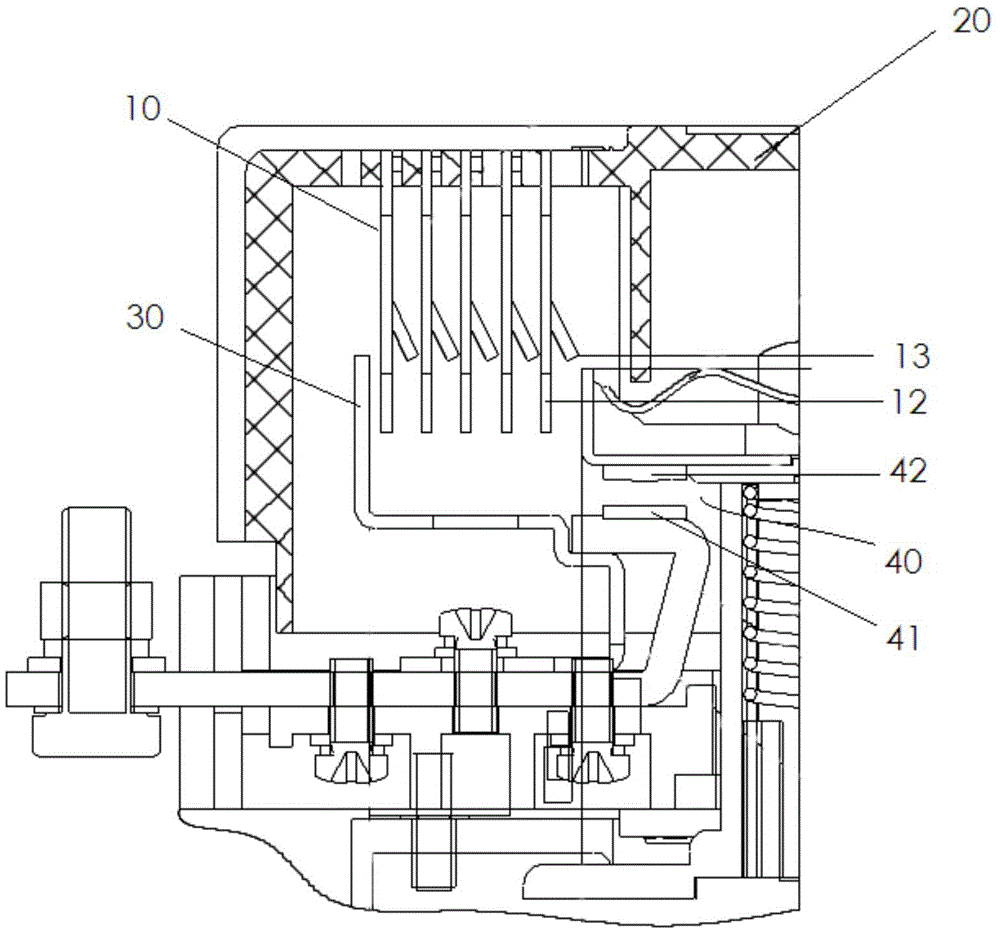

[0038] This embodiment provides an arc extinguishing chamber, refer to figure 2 , the arc extinguishing chamber of this embodiment includes an arc extinguishing cover 20, and in the arc extinguishing cover 20, several arc extinguishing grids described in Embodiment 1 are arranged in parallel at intervals, and the protruding part on each grid body 10 13 protrudes toward the side where the arc is generated, and the protruding part 13 is not in contact with the adjacent grid body 10; it also includes an arc strike plate 30 for striking the arc to the arc extinguishing grid, wherein the arc is generated At image 3 , Figure 4 The contact assembly 40 is shown.

[0039] Further, the distance between adjacent grid bodies 10 is the same, and the distance is 2-4.5 mm.

[0040] As an implementation, when the circuit breaker or contactor is of large capacity, the distance between each grid body 10 can be selected but not limited to 3-4.5mm; when the circuit breaker or contactor is o...

Embodiment 3

[0044] This implementation provides a circuit breaker, including: the arc extinguishing chamber described in Embodiment 2, and a contact assembly 40, the arc strike plate 30 in the arc extinguishing chamber is close to the static contact 41 in the contact assembly 40 It is provided that the end of the arc strike plate 30 extends close to the one of the arc extinguishing grids that is furthest from the contact assembly 40 .

[0045] Further, the protruding portion 13 of the arc extinguishing grid which is closest to the contact assembly 40 is arranged close to the movable contact 42 of the contact assembly 40 .

[0046] Further, the moving contact 42 is a bridge contact.

[0047] The arc extinguishing process of the circuit breaker of this embodiment is as follows:

[0048] refer to image 3 , 4 , the arc is generated at the contact assembly 40. After the arc is generated, a part of the arc passes through the moving contact 42 and is guided by the protruding part 13 on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com