A kind of automatic tar residue harmless treatment method

A technology of harmless treatment and tar residue, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures. It can solve the problems of reducing the viscosity of tar residue and easy blockage of tar residue, and achieves effective utilization, smoothness and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

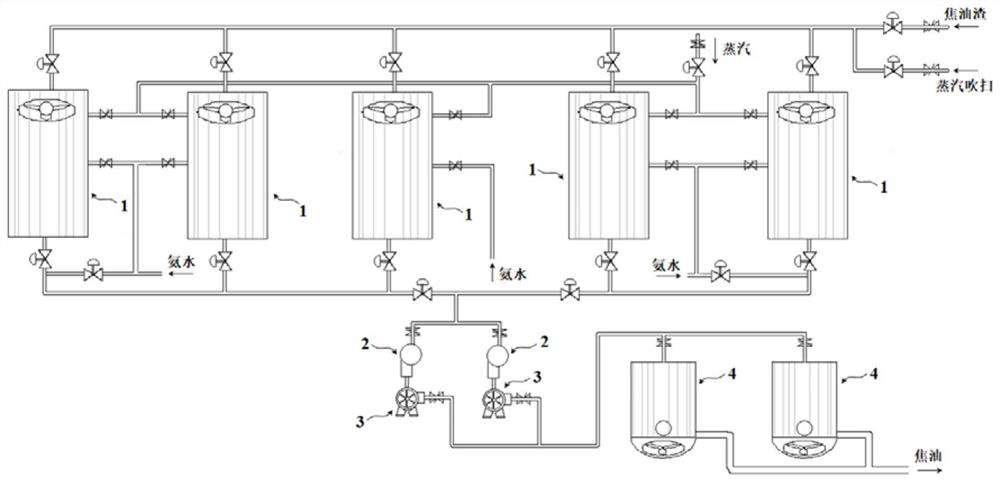

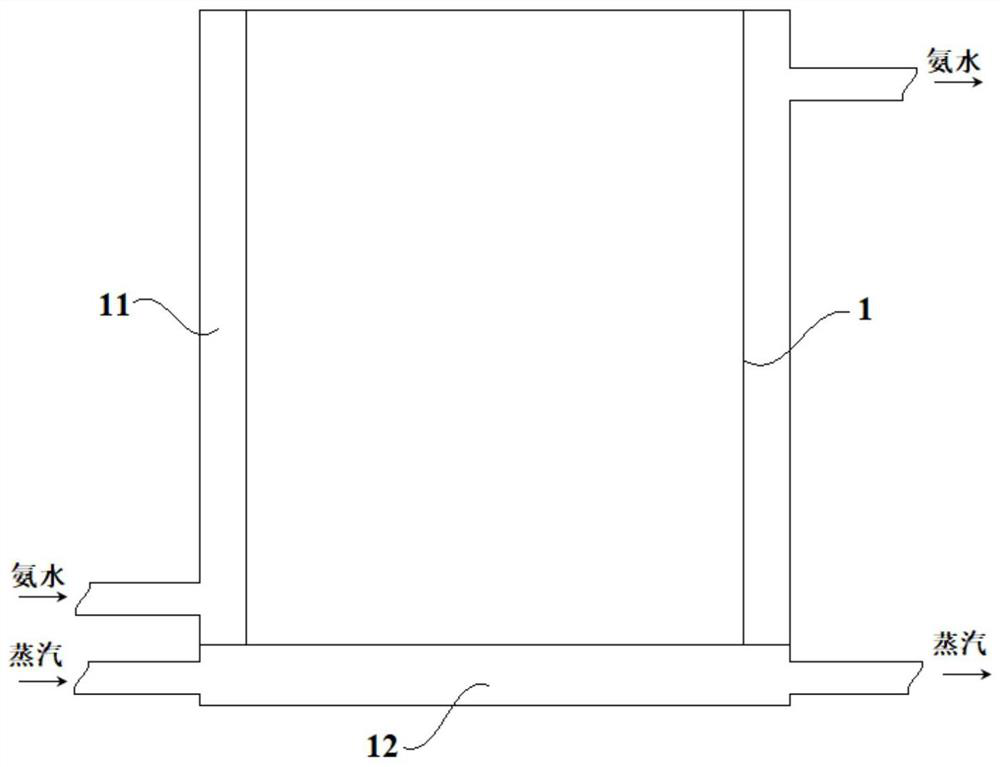

[0033] A fully automatic tar residue harmless treatment system of this embodiment, combined with figure 1 , the system includes a liquefaction tank 1, a grinder 2, a transfer pump 3 and a centrifuge 4, wherein the liquefaction tank 1 is communicated with the mechanized clarification tank through a pipeline, so that the tar residue in the mechanized clarification tank can be easily transported to the liquefaction tank In 1, the liquefaction tank 1 is equipped with a stirring paddle for stirring and breaking the tar residue; the grinder 2 in this embodiment is connected to the liquefaction tank 1 through a conveying pipeline, and is used for the tar residue once broken from the liquefaction tank 1. Secondary crushing; the tar residue after secondary crushing is sent to the centrifuge 4 through the conveying pump 3, and the tar and the residue in the tar residue are separated from each other by the centrifuge 4, and the separated tar is sent to the mechanized clarification tank of...

Embodiment 2

[0053] A fully automatic tar residue harmless treatment method of the present embodiment is basically the same as Embodiment 1, and its difference is:

[0054] In step a in this embodiment, the stirring rate of the stirring paddle of the stirring system is 5 minutes per hour; the tar residue is stirred and broken by the stirring paddle in the stirring system, and the larger agglomerates are broken, that is, the tar The slag is crushed once to ensure that the tar residue in the liquefaction tank 1 is fully liquefied and crushed.

[0055] In step b, when the liquid level in the liquefaction tank 1 reaches 3 / 10, the steam purging pipeline is opened, and the tar residue in the pipeline and the tar residue remaining on the pipeline wall are blown into the liquefaction tank 1 .

[0056] In step c, when the liquid level in the liquefaction tank 1 reaches 3 / 5, then the centrifuge 4, the grinder 2 and the transfer pump 3 are turned on in sequence.

[0057] In step e, control the flush...

Embodiment 3

[0059] A fully automatic tar residue harmless treatment method of the present embodiment is basically the same as Embodiment 1, and its difference is:

[0060] In the present embodiment, in step a, the stirring rate of the stirring paddle is controlled to be 8 minutes per hour; in step b, when the liquid level in the liquefaction tank 1 reaches 7 / 20, the pipeline is purged with steam; in step c, the liquefaction tank is When the liquid level in 1 reaches 19 / 30, then turn on the centrifuge 4, the grinder 2 and the transfer pump 3 in turn; in step e, control the washing and cleaning time to be 6 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com