Maintenance device for bearing grinding wheel grinding spindle

A grinding wheel grinding and spindle technology, which is applied to workbenches, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of reducing the working efficiency of the device, reducing the accuracy of the spindle, and secondary damage to the spindle, reducing shaking and avoiding secondary damage. The effect of secondary damage and increased stress area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

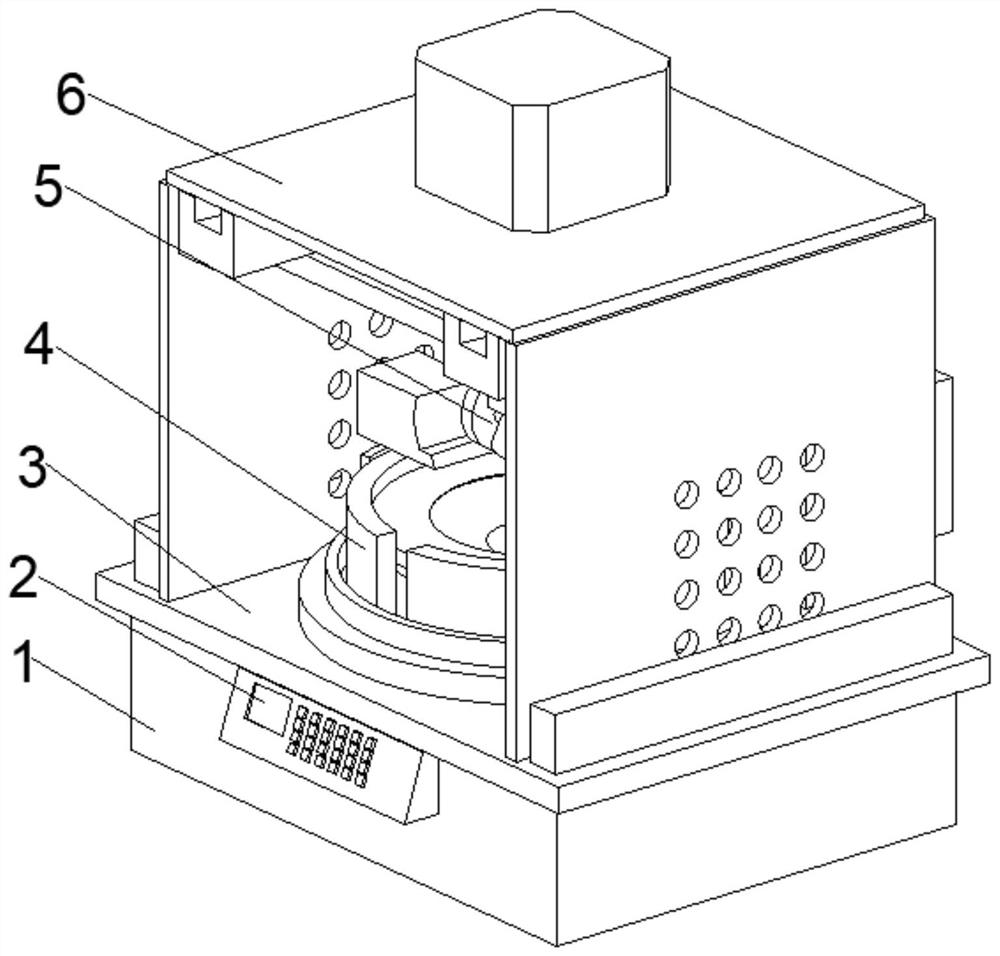

[0042] see Figure 1-6 , the present invention provides a technical solution: a maintenance device for bearing grinding wheel grinding spindle, including a stable base 1, a control panel 2 is fixedly connected to the middle position of the front top of the stable base 1, and a workbench is fixedly connected to the top of the control panel 2 3. A supporting device 4 is provided in the middle of the top of the workbench 3, and a maintenance head 5 is rotatably connected to the middle of the top of the inner cavity of the supporting device 4. A maintenance frame 6 is arranged on both sides of the top of the supporting device 4, and the two sides of the bottom of the maintenance frame 6 are Both sides are fixedly connected with the workbench 3;

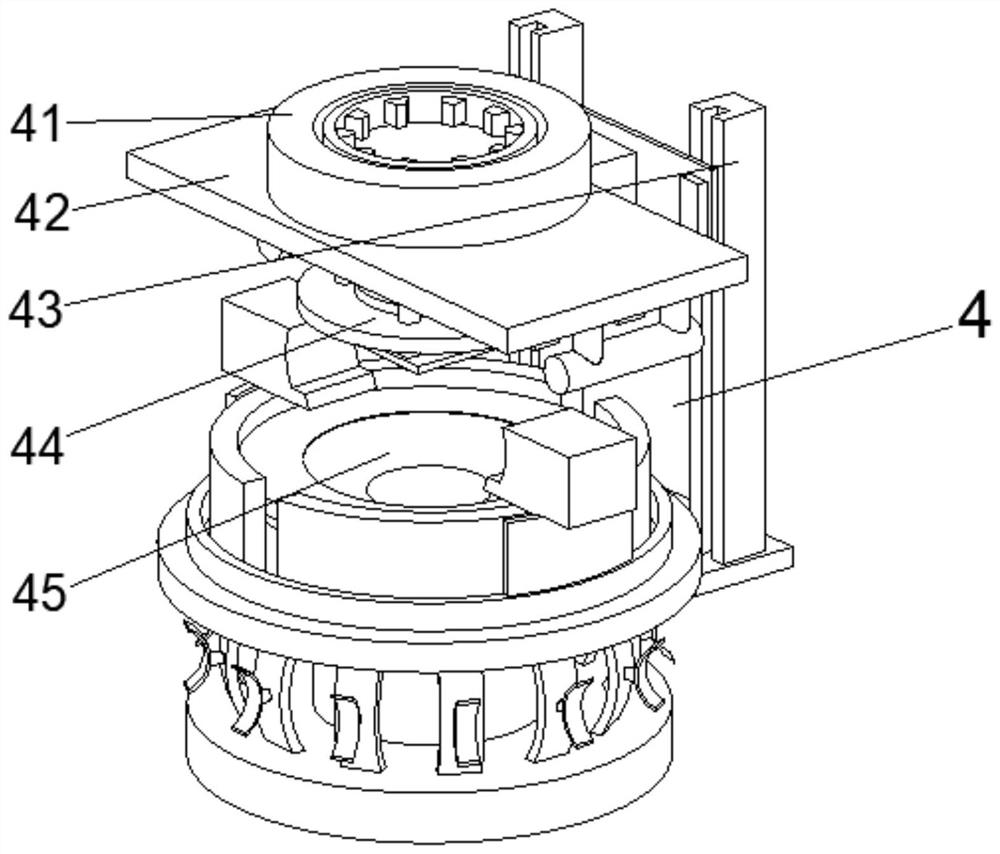

[0043] The support device 4 includes a partition plate 42, the top middle position of the partition plate 42 is rotatably connected with a transmission body 41, the surface both sides of the partition plate 42 is slidingly connected with ...

Embodiment 2

[0049] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using a maintenance device for a grinding wheel bearing grinding spindle, step 1: install and fix the equipment, and connect the workbench 3 with the stable base 1 Fixed connection, the support device 4 is fixedly connected to the workbench 1 to support and limit the internal working space, and the support device 4 is connected to the maintenance head 5 in rotation;

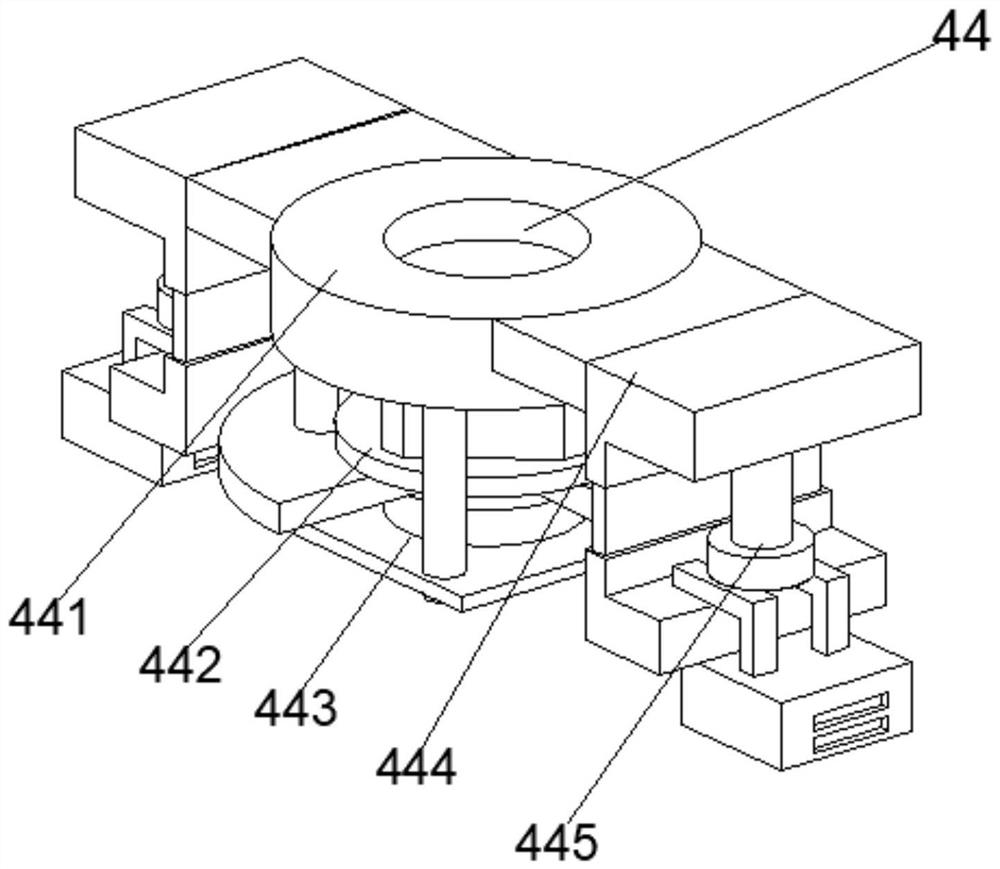

[0050] Step 2: Carry out multi-angle repair of parts through the processing cavity generated by the partition plate 42 and the placement device 45, and adjust the position of the transmission body 41 by driving the linkage device 44 to adjust the position of the partition plate 42 and the support connecting frame 43 Make a sliding connection to enable vertical lifting work;

[0051] Step 3: Use the telescopic frame 442 to drive the limit auxiliary frame 443 to carry out intermittent lifting an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com