Tin supplementing device and tin supplementing method for junction box

A junction box and tin-filling technology, which is used in tin feeding devices, welding equipment, welding/welding/cutting items, etc., can solve problems such as blockage of lead holes, improve work efficiency, and prevent lead holes of junction boxes from being easily blocked. Conducive to the effect of the tin repairing operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

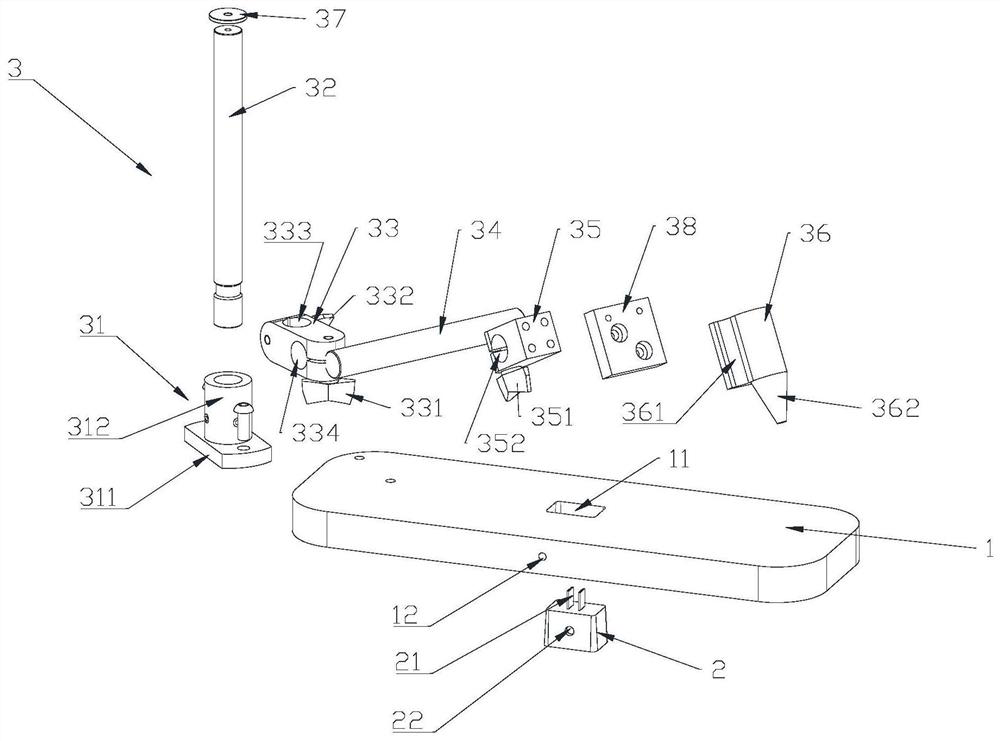

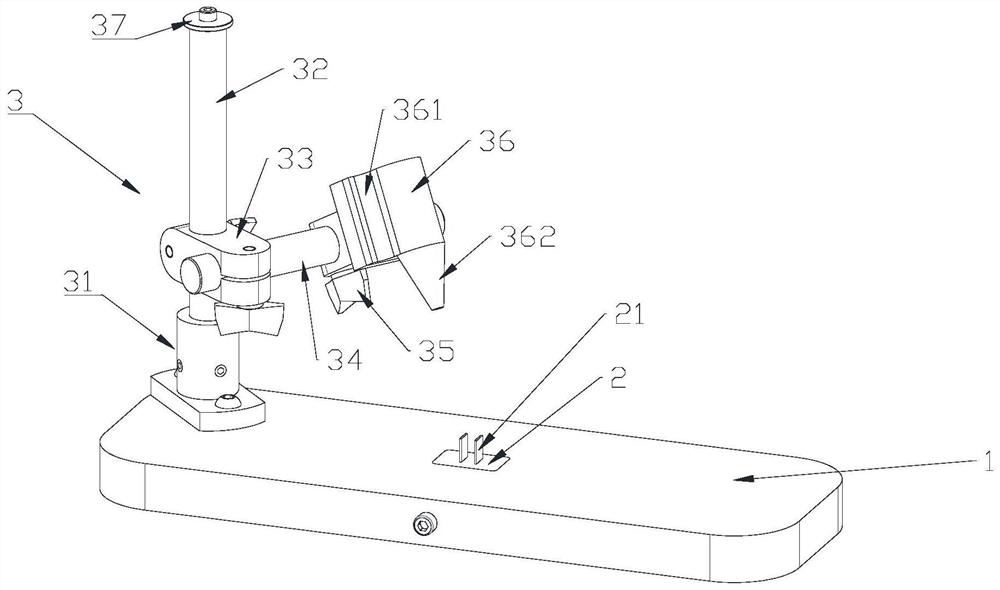

[0035] A specific embodiment of the present invention discloses a junction box filling tin device, such as figure 1 and figure 2 As shown, it includes a base 1, an anti-blocking tin mold 2 and a solder guide assembly 3, wherein the anti-blocking tin mold 2 is installed on the base 1, and the anti-blocking tin mold 2 is used to prevent the lead hole of the junction box from being blocked during the soldering process ; The solder guide assembly 3 is installed on the base 1 for fixing the tin roll and adjusting the position of the welding wire.

[0036] During the use of the junction box, since the thickness of the tin layer is not up to the standard, it is necessary to add tin to the junction box offline to increase the thickness of the tin layer, so that the tensile force when welding with the lead wire is within the standard range. Specifically, the anti-blocking tin mold 2 is installed in the junction box In the lead hole, the anti-blocking tin mold 2 has the same height as...

Embodiment 2

[0059] The present invention also provides a method for replenishing tin in a junction box, the steps comprising:

[0060] Step 1: Assemble the junction box refilling device of Example 1;

[0061] Step 2: Place the tin coil and tin wire;

[0062] Step 3: Melt the tin wire for tin filling.

[0063] details as follows:

[0064] In step 1, the base 1, the anti-blocking tin mold 2, and the solder guide assembly 3 are assembled, wherein the anti-blocking tin mold 2 is installed in the mold through hole 11 of the base 1, and the anti-blocking tin mold 2 and the base 1 are fixedly connected by bolts The support base 31 of the solder guide assembly 3 is fixedly connected with the base 1, and the two-way adjustment lock 33 is installed in the vertical support 32 and the horizontal support 34, the vertical support 32 passes through the vertical through hole 333, and the horizontal support 34 passes through the first Horizontal through hole 334; level adjustment lock 35 is installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com