Array substrate, manufacturing method of array substrate and display device

A technology of an array substrate and a manufacturing method, which is applied in the field of display, can solve problems such as poor display, poor overlap, and affecting the aperture ratio of a display device, and achieve the effects of reducing the probability of poor display, increasing the aperture ratio, and optimizing connection conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

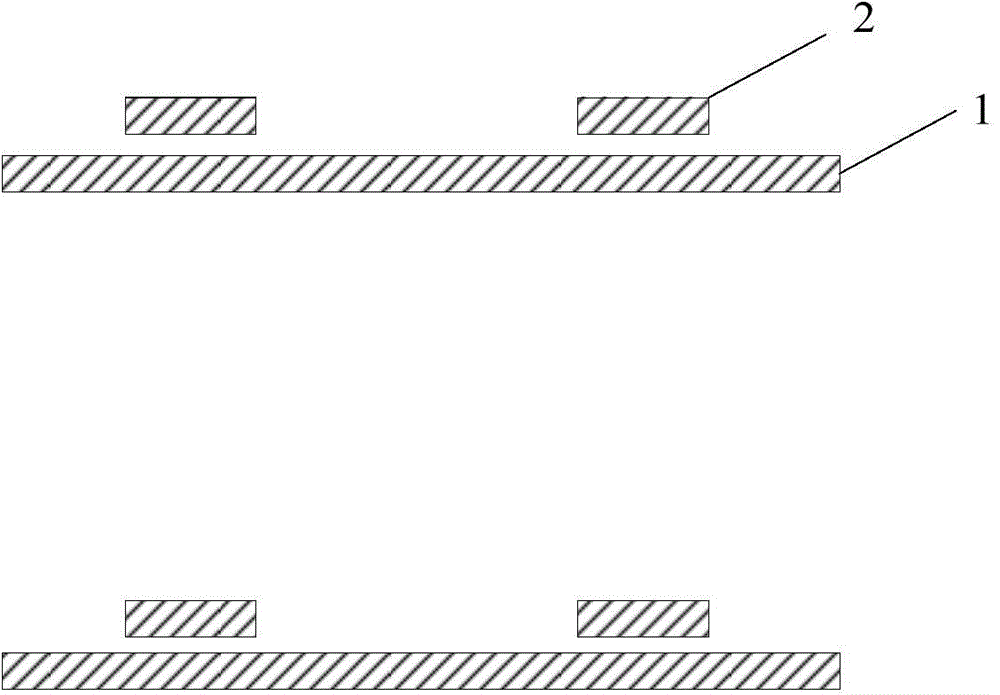

[0044] This embodiment provides an array substrate, including a gate electrode, a gate line, a gate insulating layer, a source electrode, a drain electrode, a data line, a common electrode and a common electrode line formed on the base substrate, wherein the common electrode The wire is directly connected to the common electrode.

[0045] The common electrodes of the array substrate in this embodiment are directly connected to the common electrode lines instead of through via holes, so there is no need to provide via holes for connecting the common electrode lines and common electrodes, which can improve the aperture ratio of the display device, and the common electrode The direct connection with the common electrode line can optimize the connection between the common electrode and the common electrode line, and reduce the probability of poor display.

[0046] In a specific embodiment, the common electrode line and the source electrode, the drain electrode, and the data line a...

Embodiment 2

[0053] This embodiment provides a display device, including the above-mentioned array substrate. The display device can be any product or component with a display function such as a liquid crystal panel, a liquid crystal TV, a liquid crystal display, a digital photo frame, a mobile phone, a tablet computer, a navigator, and an electronic paper.

Embodiment 3

[0055] This embodiment provides a method for fabricating an array substrate, the array substrate comprising a gate electrode, a gate line, a gate insulating layer, a source electrode, a drain electrode, a data line, a common electrode and a common electrode line formed on a base substrate, Wherein, the preparation method includes:

[0056] A directly connected common electrode line and common electrode are formed.

[0057] The common electrodes formed in this embodiment are directly connected to the common electrode lines, rather than through via holes, so there is no need to provide via holes for connecting the common electrode lines and the common electrodes, and the aperture ratio of the display device can be improved. The direct connection of the common electrode lines can optimize the connection between the common electrodes and the common electrode lines and reduce the probability of poor display.

[0058] In a specific embodiment, the manufacturing method includes:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com