Fuel cell cooling system utilizing phase change cooling

A fuel cell and heat dissipation system technology, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problems of large coolant flow, large parasitic power of auxiliary systems, etc., and achieve small cooling flow and small parasitic power , the effect of maintaining temperature balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

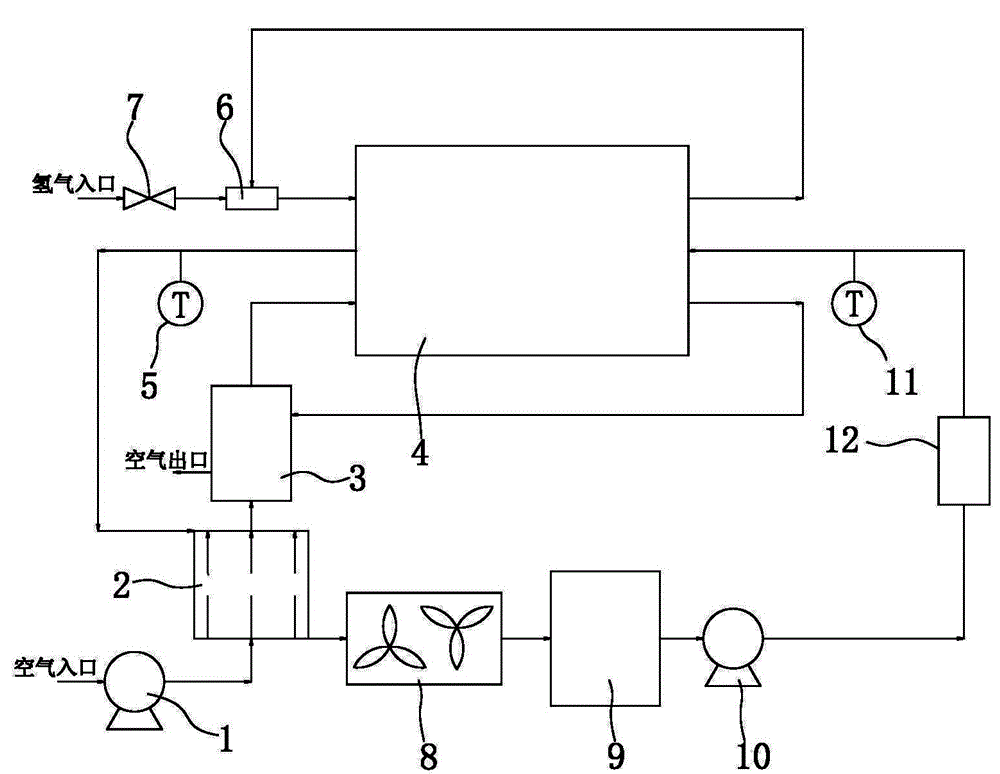

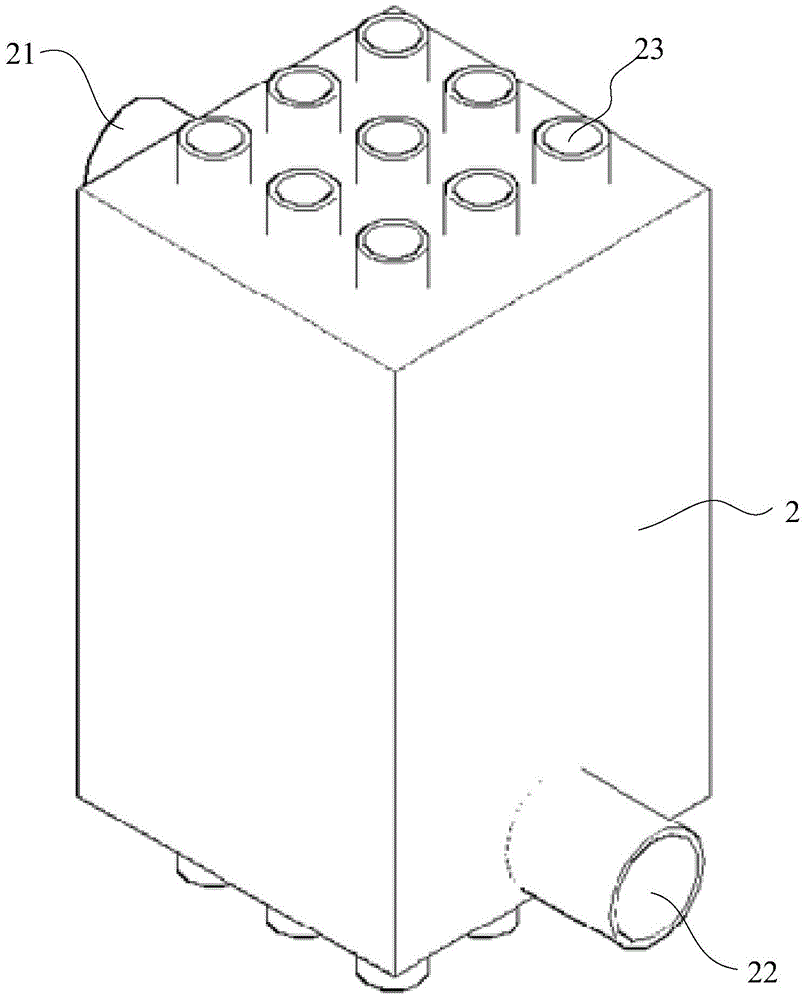

[0023] Such as Figures 1 to 2 As shown, a fuel cell cooling system utilizing phase change cooling includes an electric stack 4, a cathode air supply module connected to the electric stack 4 and used to supply air to the electric stack 4, and also includes a cathode air supply module for cooling the electric stack 4. The electric stack 4 is also a coolant circulation module capable of preheating the air in the cathode air supply module. The fuel cell heat dissipation system using phase change cooling uses the coolant circulation module to cool the inside of the stack, and circulates the heat-absorbed coolant to the air during the cooling of the stack, and the air that will enter the stack Pre-heating is carried out to improve rapid response and efficiency, and maintain the temperature balance in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com