Negative electrode material for lithium ion secondary battery, negative electrode sheet for lithium ion secondary battery, and lithium secondary battery

A secondary battery and negative electrode material technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of small capacity and large irreversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

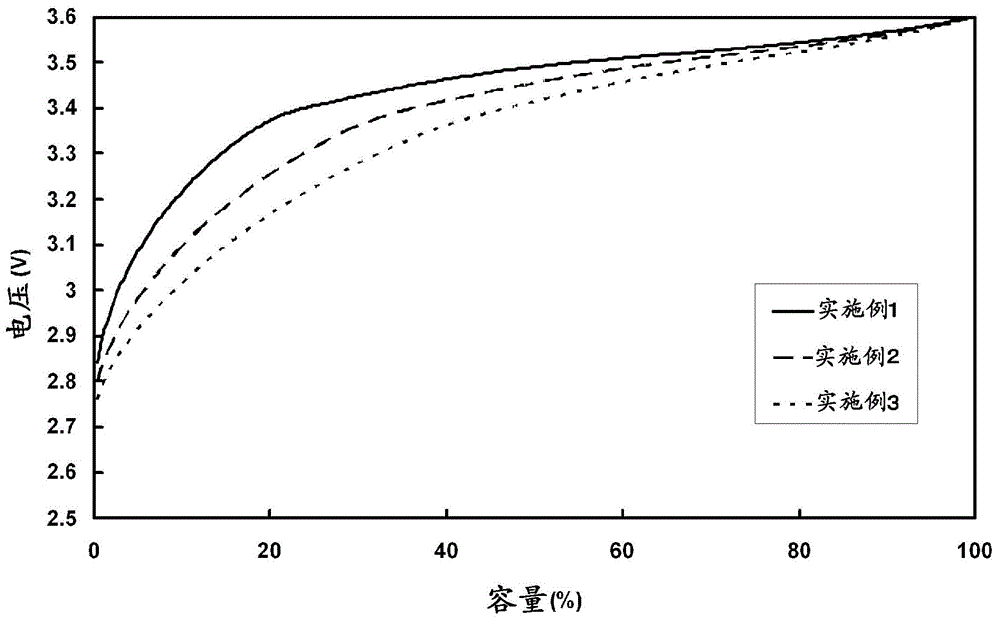

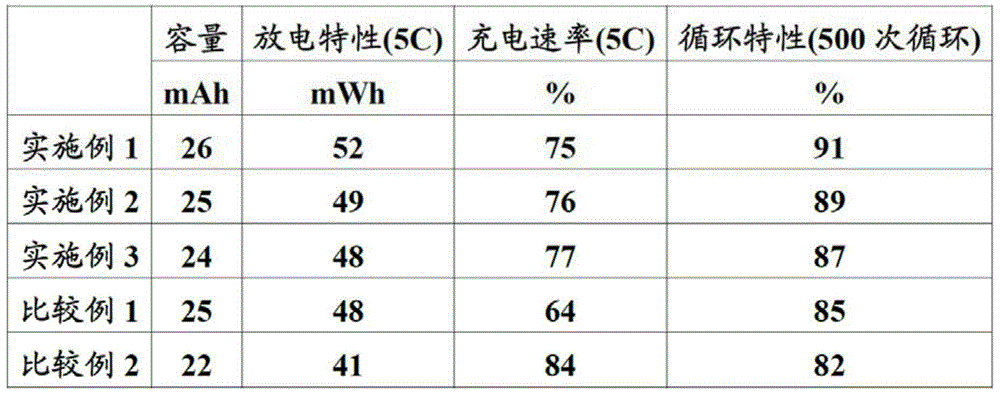

[0147] 70 parts by mass of artificial graphite (A) and 30 parts by mass of carbon material (B) were placed in a high-speed mixer made by Fuji Pandal, and mixed for 5 minutes to obtain a negative electrode material. The obtained negative electrode material has a D50 of 8.2 μm and a BET specific surface area of 2.6 m 2 / g. Electrodes and battery cells were produced using this negative electrode material, and battery characteristics were evaluated. The results are shown in Table 1.

Embodiment 2

[0149] Except changing the amount of artificial graphite (A) to 50 parts by mass, and the amount of carbon material (B) to 50 parts by mass, a negative electrode material, an electrode, and a battery cell were produced in the same manner as in Example 1. The obtained negative electrode material has a D50 of 9.9 μm and a BET specific surface area of 2.6 m 2 / g. The battery characteristics are shown in Table 1.

Embodiment 3

[0151] Except changing the amount of artificial graphite (A) to 30 parts by mass and the amount of carbon material (B) to 70 parts by mass, a negative electrode material, an electrode, and a battery cell were produced in the same manner as in Example 1. The obtained negative electrode material has a D50 of 11.4 μm and a BET specific surface area of 2.5 m 2 / g, the battery characteristics are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com