Pesticide composition containing halosulfuron-methyl, aminopyralid and nicosulfuron

A technology of pyridoxine and chlorpyrifosulfuron is applied in the field of pesticides, which can solve the problems of weeds in corn fields that are prone to produce drug resistance and control effects, and achieve the effect of expanding the herbicidal spectrum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

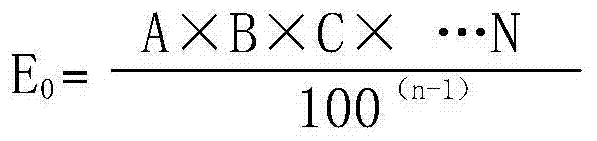

Method used

Image

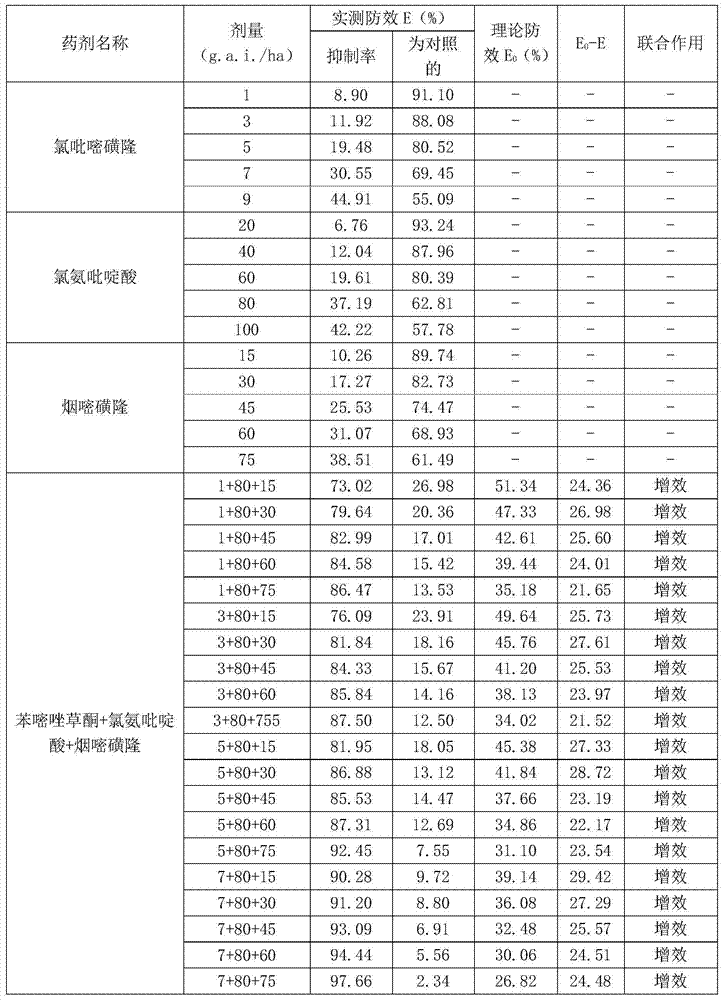

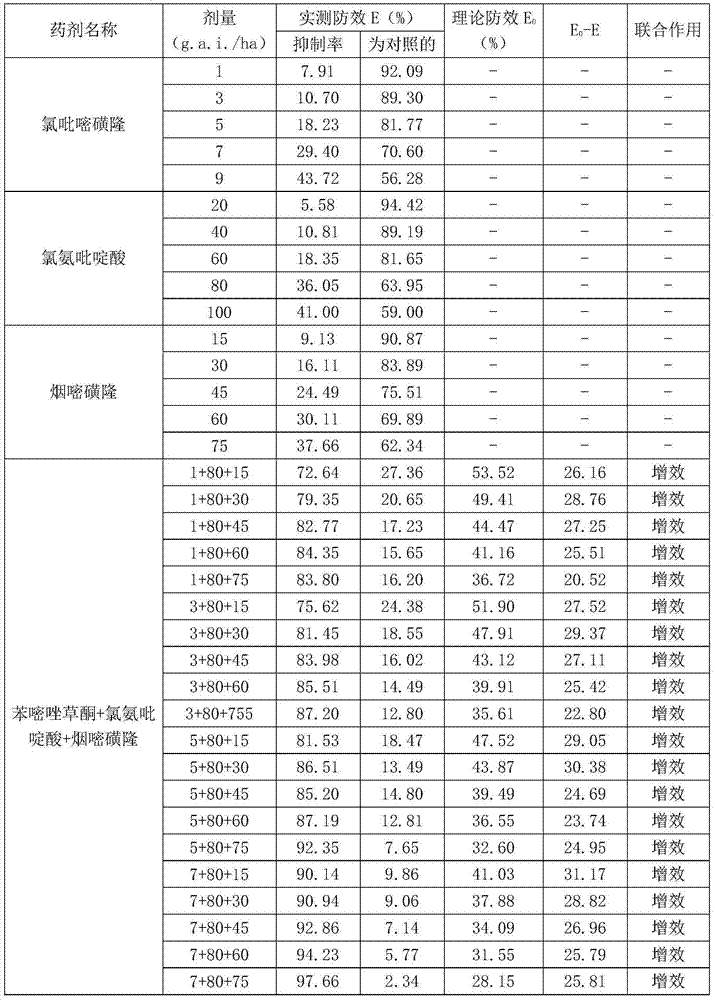

Examples

Embodiment 1

[0031] Formulation example 1: 27% chlorpyrazosulfuron-aminopyralid-nicotinesulfuron water-dispersible granules.

[0032]

[0033] Put the above materials together into the conical mixer and mix them evenly, and then crush them through the jet mill, and then mix the crushed materials through the conical mixer. Knead into a plastic material, and finally put the material into an extrusion granulator to extrude and granulate. After granulation, it is dried and sieved to obtain 27% chlorpyrazosulfuron-aminopyralid-nicotine Longshui dispersible granules.

Embodiment 2

[0034] Formulation example 2: 30% chlorpyrazosulfuron-aminopyralid-nicotinesulfuron wettable powder.

[0035]

[0036] Add the above materials together into a conical mixer and mix them evenly, then pulverize them through a jet mill, and then mix the pulverized materials through a conical mixer. The fineness of the mixed materials is 98% and passes through a 600-mesh standard sieve to obtain 30% Clopyrazosulfuron, aminopyralid, nicosulfuron wettable powder.

Embodiment 3

[0037] Formulation example 3: 20% chlorpyrazosulfuron-aminopyralid-nicotinesulfuron suspension concentrate.

[0038]

[0039] The above formula is pre-pulverized according to the proportion, then put into a sand mill for grinding, and then prepared after high-shear mixing to obtain 20% chlorpyrazosulfuron-aminopyralid-nicotinesulfuron suspension concentrate.

[0040] Formulation example 4: 23% chlorpyrazosulfuron·aminopyralid·nicotinesulfuron oil suspension.

[0041]

[0042] Put the above materials (except organic bentonite) into the reaction kettle mixer together, stir for 2 hours, open the feed valve at the bottom of the kettle, inject the materials into the multi-stage sand mill for grinding, and the fineness of the ground materials is 98% through 1- After 5um, the material is discharged, and the material is put into a high-shear emulsification kettle together with the pre-dissolved organic bentonite. After emulsification, it can be made into 23% chlorpyrazosulfuron-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com