Swinging device for uniformly mixing liquid

A swing mechanism and drive motor technology, applied in the field of biochemical instruments, can solve the problems of reliability, control precision, large difference between vibration and noise, unstable quality of supporting equipment, etc. and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

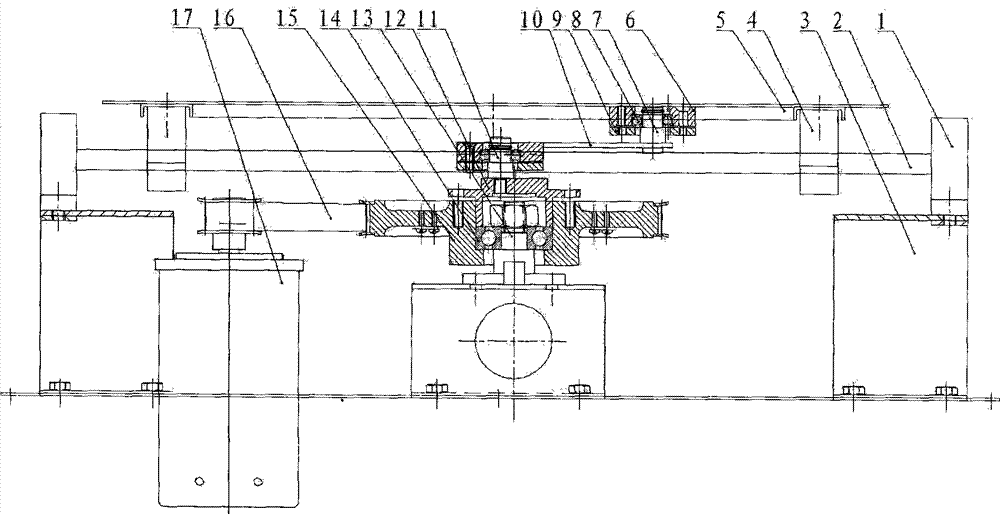

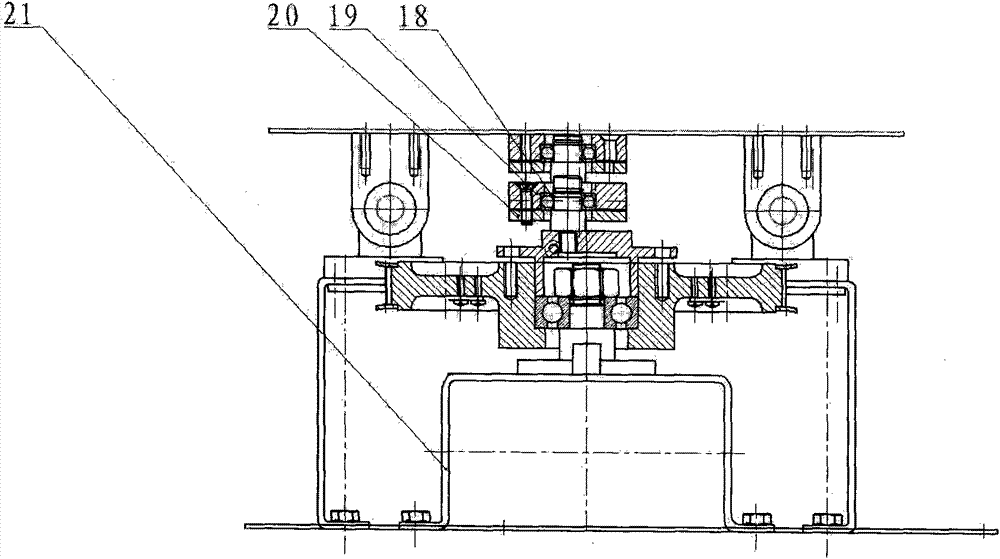

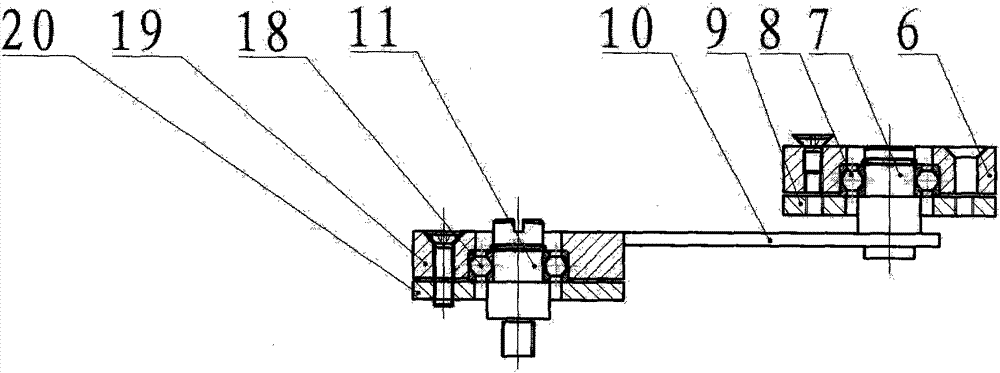

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0032] The present invention will be described in further detail below in conjunction with embodiment accompanying drawing:

[0033] Referring to the accompanying drawings, the driving motor (17) is connected with the speed change pulley (15) through the synchronous belt (16), and the speed change pulley (15) is positioned and installed on the support center shaft (13) after tight fitting with the support center shaft bearing (14) Go up, support central shaft bearing (14) with nut positioning simultaneously, support central shaft (13) be fixed on the variable speed pulley support (21) with screw. The eccentric wheel (12) is fixed on the variable speed pulley (15), the eccentric wheel shaft (11) is fixed on the eccen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com