Welding robot

A welding robot and welding mechanism technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low welding forming quality and low degree of automation, and improve welding forming quality and automation intelligence. The degree of transformation and the effect of increasing the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

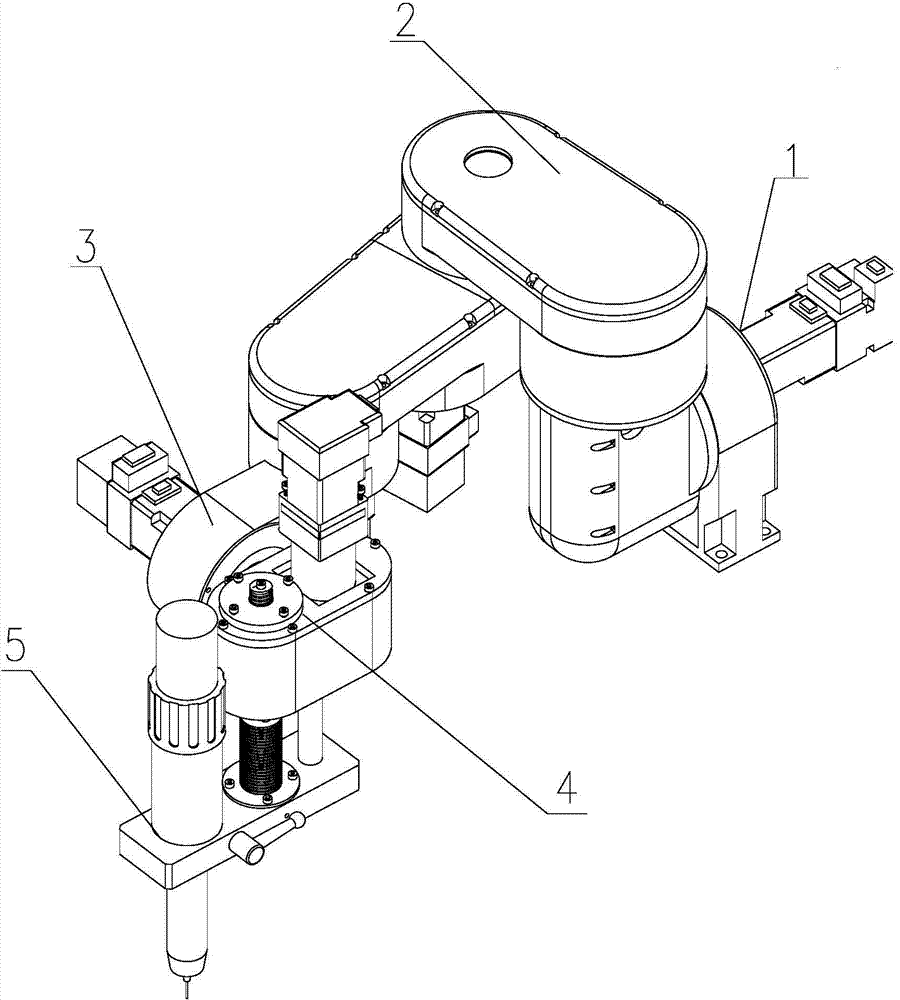

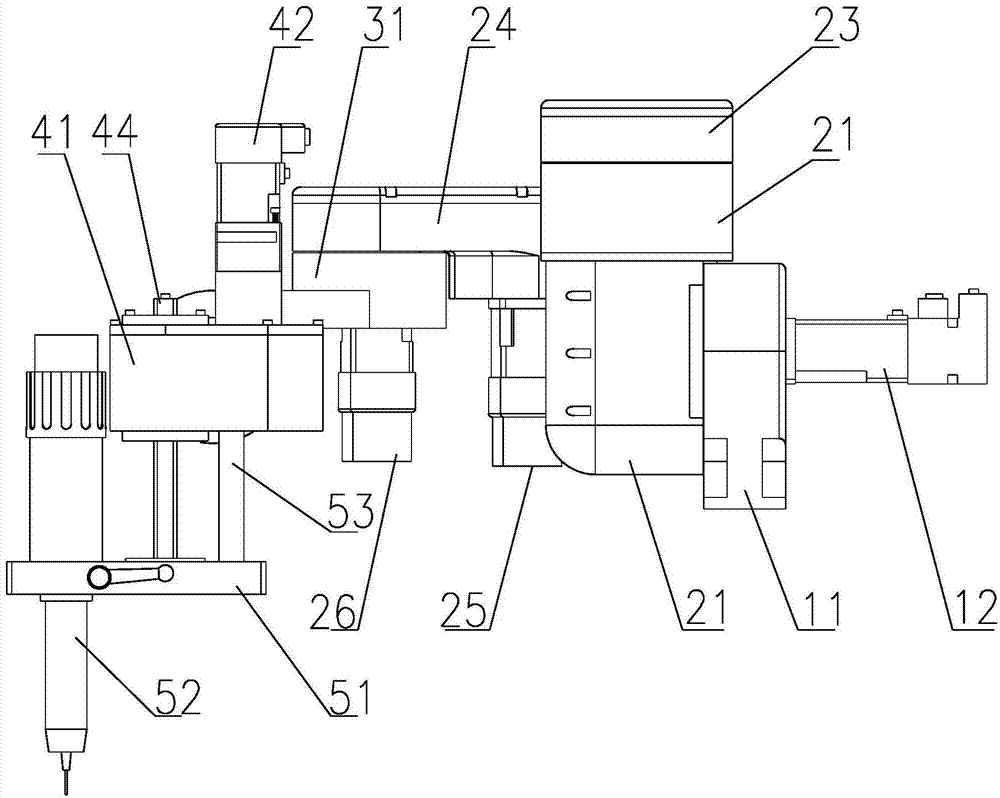

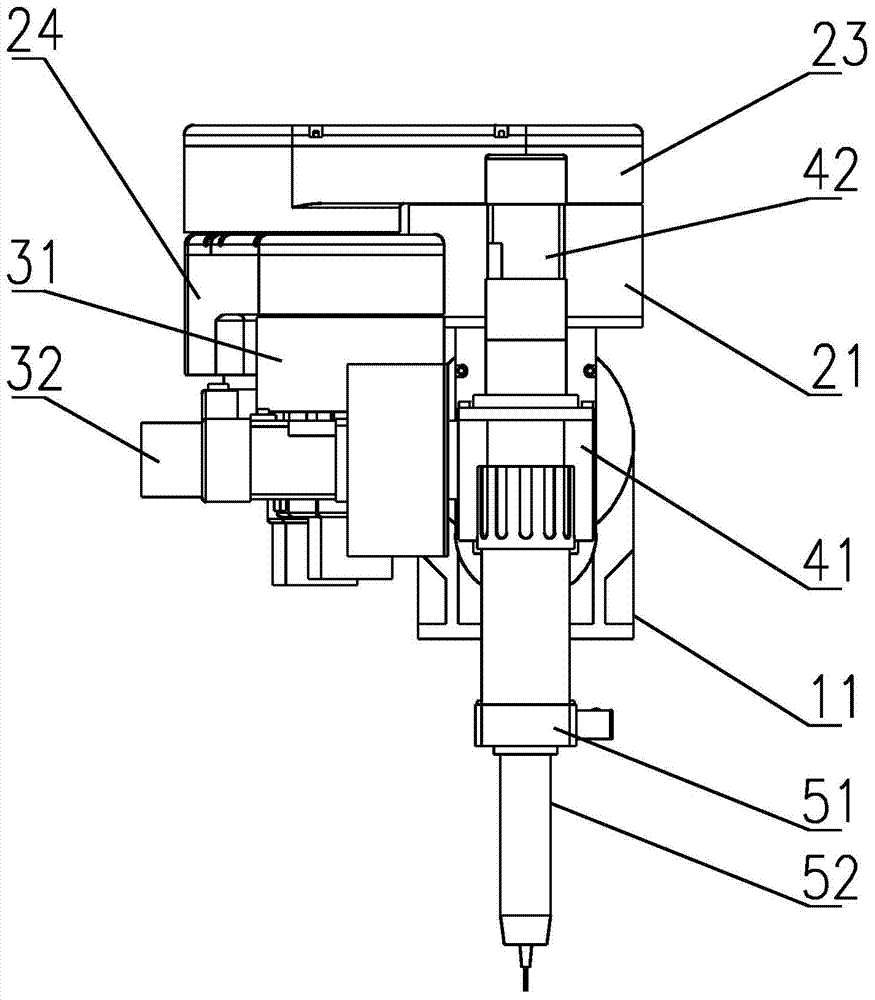

[0024] In order to solve the technical problem that the existing automatic welding machine has a low degree of automation, which will lead to low welding quality, the embodiment of the present invention provides a welding robot. The general idea is as follows:

[0025] The execution terminal of the small multi-axis open chain welding robot provides a larger working range and spatial accessibility for all-position welding of pipelines. The posture of the welding torch is automatically adjusted in real time according to the change of the welding position, thereby improving the performance of all-position welding of pipelines The degree of automation and intelligence improves the quality of welding forming.

[0026] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com