Photovoltaic solar cell composite backboard, preparation method and assembly thereof

A technology for solar cells and back sheets, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the problems of weather resistance of solar cell back sheets, weak water vapor barrier insulating back sheet strength, etc. Achieve the effect of high bond strength, lower production cost, and reduced use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

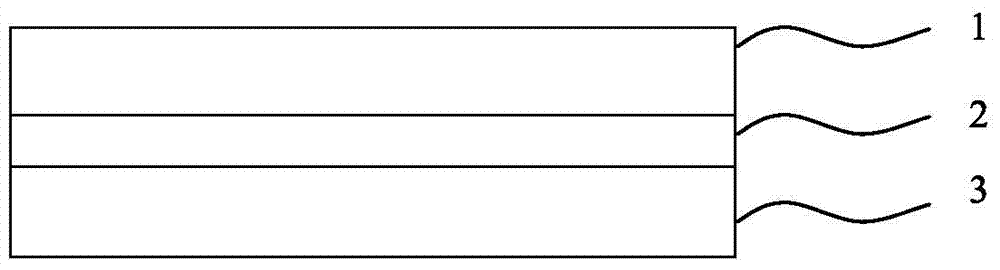

[0037] Such as figure 1As shown, this embodiment provides a photovoltaic solar cell composite back sheet, including an outer polyethylene terephthalate (PET) and polyester coextrusion layer 1, an intermediate adhesive layer 2, an inner layer of poly Ethylene (PE) and olefin polymer co-extrusion layer 3; the thickness of the outer polyethylene terephthalate and polyester co-extrusion layer 1 is the same as that of the inner layer polyethylene and olefin polymer co-extrusion The thickness ratio of the exit layer 3 is 1:5˜16:1. The outer coextruded layer is mainly polyethylene terephthalate (PET) and coextruded with various polyesters, and the inner coextruded layer is mainly polyethylene (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com