Humic acid organic-inorganic complex water flush fertilizer production line

A humic acid, production line technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of high labor intensity, low efficiency, poor product quality, etc., to improve mixing uniformity, improve working environment, and prevent dust from spreading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further clearly and completely described in conjunction with the accompanying drawings in the embodiments of the present invention, and the described embodiments are only some of the embodiments of the present invention, not all of them.

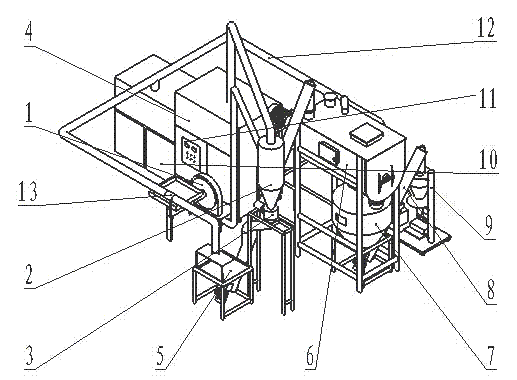

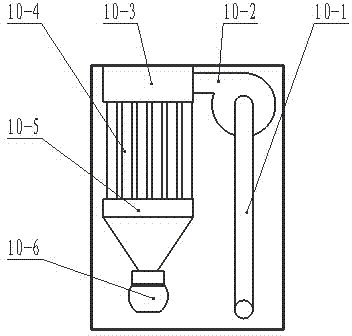

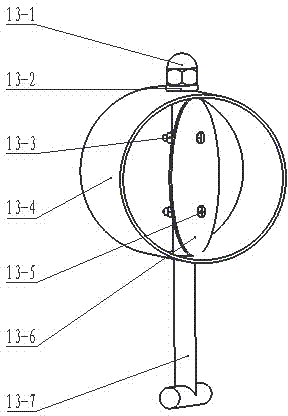

[0034]An organic-inorganic compound fertilization production line, including crushing equipment, a first feeding machine 5, a mixer 6, a buffer hopper 7, a second feeding machine 8, a quantitative powder packaging machine 9, a dust removal device 10 and a control system 11, Wherein the pulverizing equipment is used for pulverizing the raw materials that need to be pulverized, and the pulverizing equipment has a bag filter 4; the first feeder 5 is connected with the pulverizing equipment, and is used to transport the pulverized raw materials and the raw materials that do not need pulverizing; the mixer 6 has The material inlet 6-1 and the material outlet 6-6, the material inlet 6-1 is connected with the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com