Polyamide acid solution, polyimide film, preparation method and application method

A technology of polyimide film and polyamic acid is applied in the field of preparation of ultra-thin polyimide film, which can solve the problems of difficulty in developing ultra-thin polyimide film and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

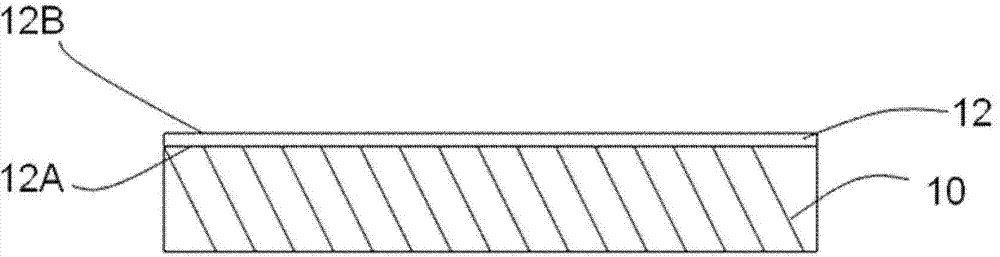

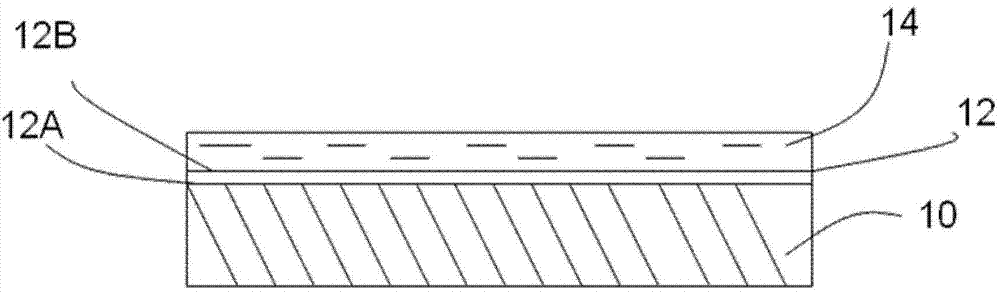

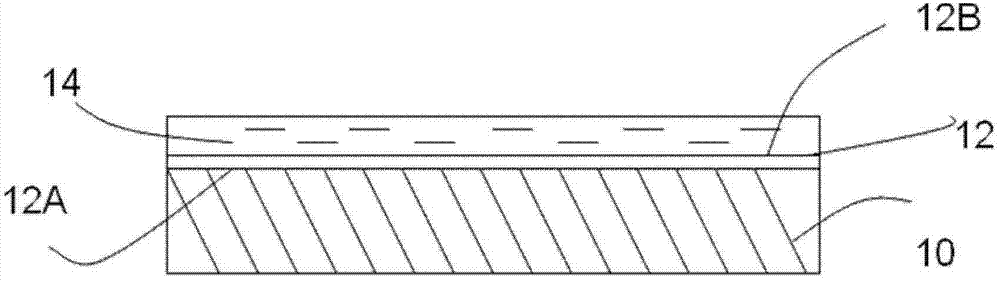

[0040] For the preparation method of the polyimide film containing siloxane of the present invention, please refer to image 3 As shown, it includes the following steps:

[0041] Prepare a peelable base layer 10, which includes polyimide and siloxane structure, the siloxane structure is

[0042]

[0043] The n is a repeating unit, the silicon atom accounts for 1-12% of the total weight of the peelable base layer, and the Y is a diamine or a dianhydride. In addition, the polyimide can further include an R, which is an aliphatic group with 1-10 carbons, such as methyl, ethyl or propyl, or aromatic, to form the following structure

[0044] and

[0045] Coating a polyamic acid solution on the peelable base layer 10; heating the polyamic acid solution to form a polyimide layer 12 on the peelable base layer.

[0046] In addition, the peelable base layer 10 can be in a liquid state, and the polyamic acid system is heated together with the liquid peelable base layer, and baked...

Embodiment 1

[0063] Preparation of the first polyamic acid solution

[0064] Put 44.31 grams of ODA and 400 grams of solvent DMAc into a three-neck flask, stir at 30°C until completely dissolved, then add 5.89 grams of siloxane (PDMS), and then add 49.05 grams of PMDA after it is evenly mixed. , the monomer accounts for 20wt% of the total weight of the reaction solution. Then, the first polyamic acid solution was obtained by continuously stirring and reacting at 25° C. for 25 hours.

[0065] Preparation of the second polyamic acid solution

[0066] Put 47.85 grams of ODA and 400 grams of solvent DMAc into a three-neck flask, stir at 30°C until completely dissolved, then add 51.37 grams of PMDA, wherein the monomer accounts for 20wt% of the total weight of the reaction solution, and then continue stirring at 25°C And react for 25 hours to obtain the second polyamic acid solution.

[0067] Preparation of ultrathin polyimide film

[0068] Coat the obtained first polyamic acid solution on ...

Embodiment 2

[0070] The steps of Example 1 were repeated, but the components of the first polyamic acid solution were changed to 42.13 grams of ODA, 9.53 grams of PDMS, and 48.1 grams of PMDA. In this example, the monomers accounted for 20 wt% of the total weight of the reaction solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com