Method for manufacturing three-dimensional member via local etching and positioning tool

A technology of partial etching and positioning fixture, applied in the field of hardware etching, can solve the problems of three-dimensional parts failing to meet the accuracy requirements, cost waste, low pass rate, etc., and achieve the effect of exquisite appearance, strong three-dimensional effect and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

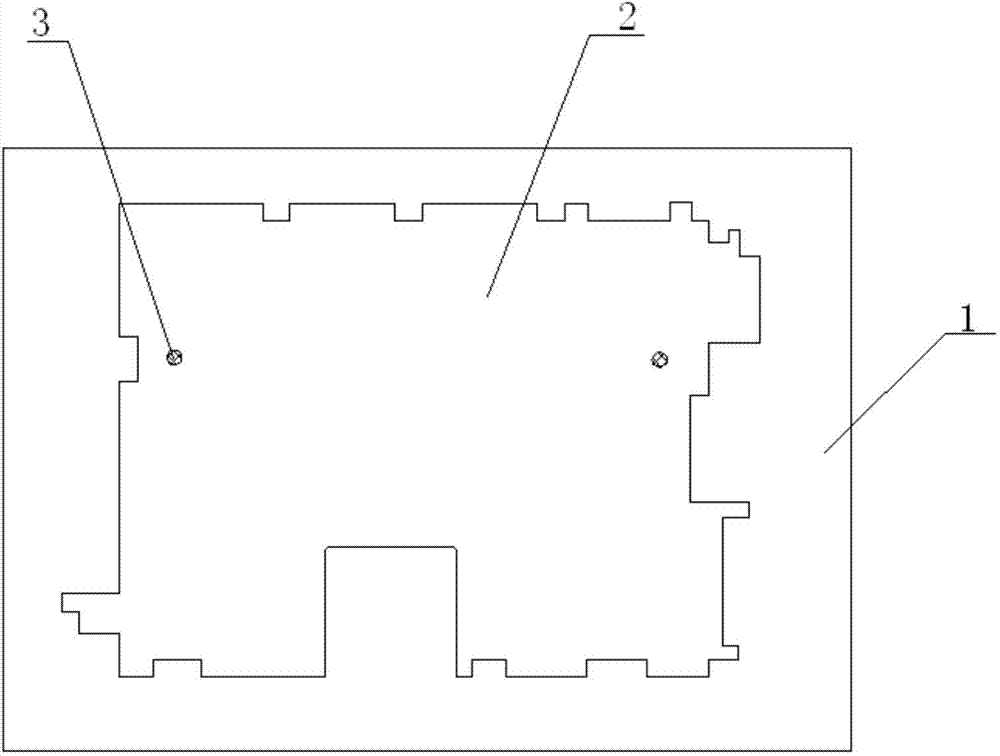

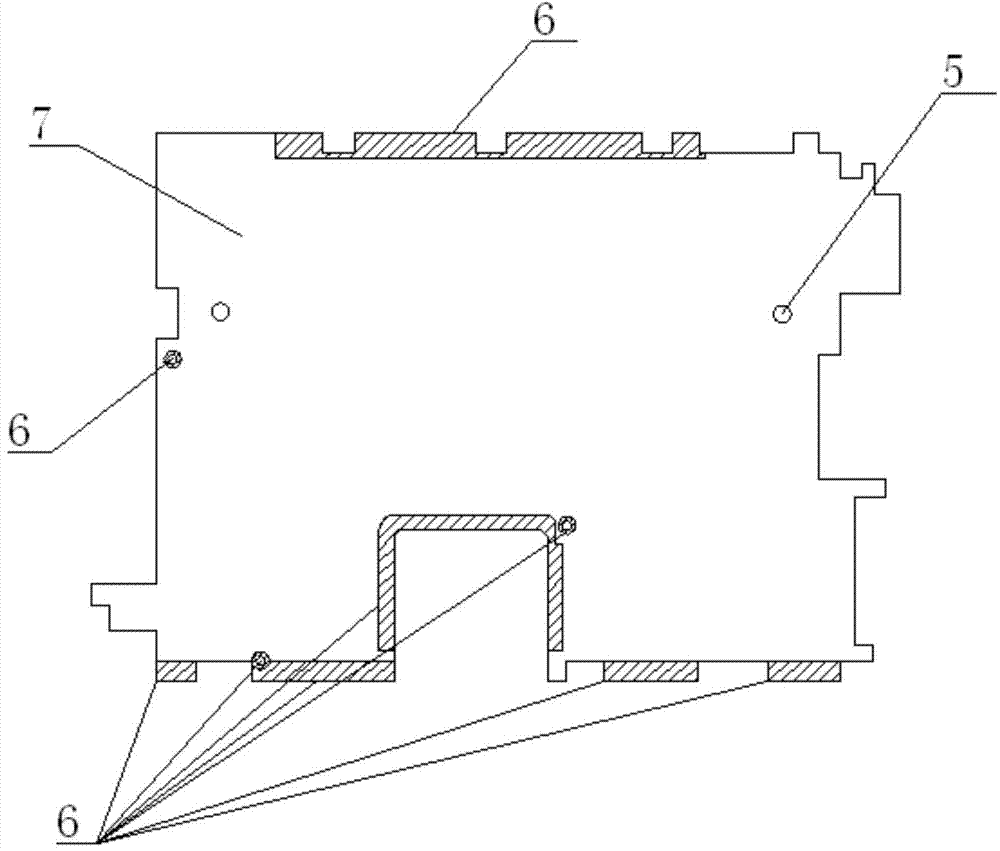

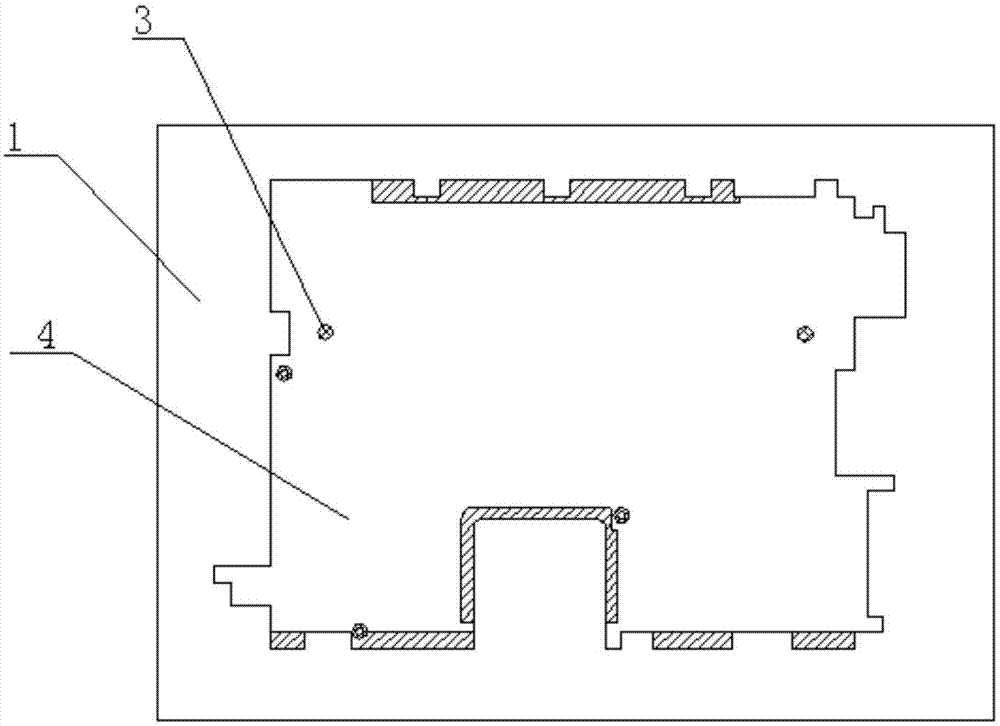

[0026] Such as figure 1 , figure 2 with image 3 Shown, a kind of method for local etching to make three-dimensional piece, comprises the steps:

[0027] a. Make a positioning fixture according to the shape of the three-dimensional part to be etched;

[0028] b. Coating a layer of photosensitive ink on the surface 7 of the three-dimensional part to be etched that needs to be etched by electrophoresis;

[0029] c. Remove the photosensitive ink covering the part 6 that needs to be etched on the surface in step b through the laser engraving process, and expose the part that needs to be etched;

[0030] d, positioning the three-dimensional part to be etched formed in step c on the positioning jig, and putting the positioning jig into an etching machine to etch with a preset corrosion solution to a set depth;

[0031] e. Perform film removal, cleaning and drying on the three-dimensional parts etched in step d.

[0032] Preferably, the three-dimensional element is a metal subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com