Flax splitting machine

A beam splitter and flax technology, applied in mechanical processing, fiber mechanical separation, textile and paper making, etc., can solve the problems of high labor intensity, monotonous repetitive work, and low work efficiency, and achieve simple overall structure, convenient use, and maintenance convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings of the specification, but the present invention is not limited to the following embodiments.

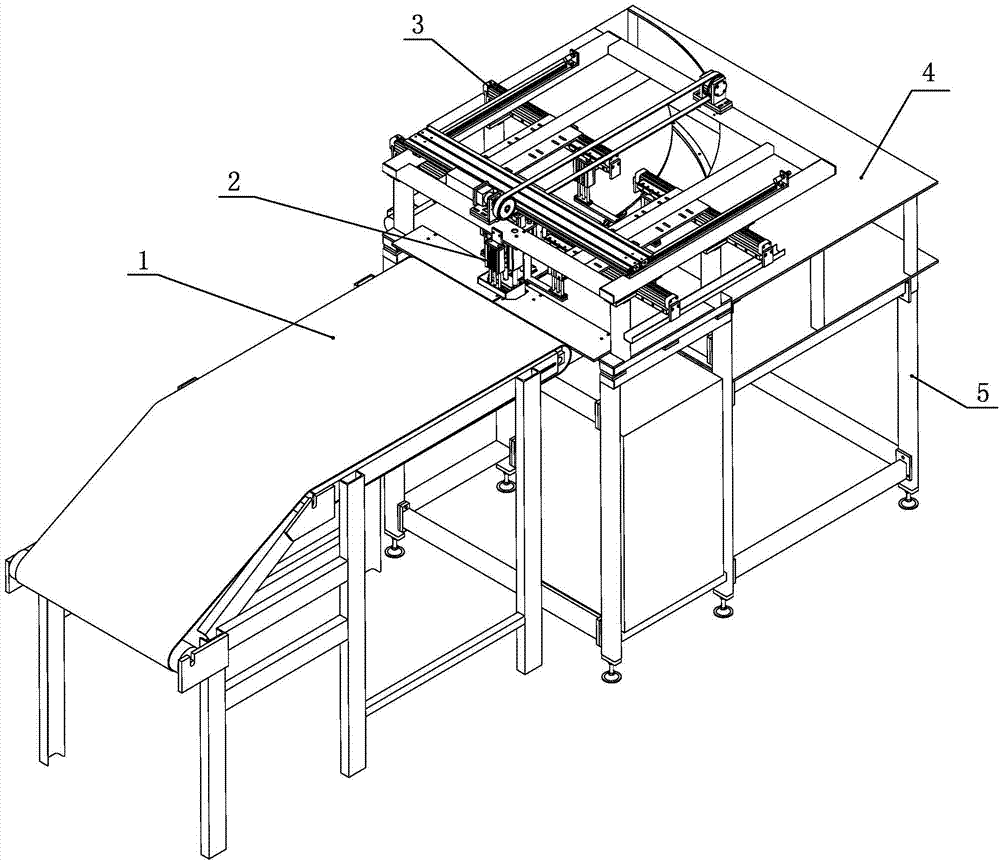

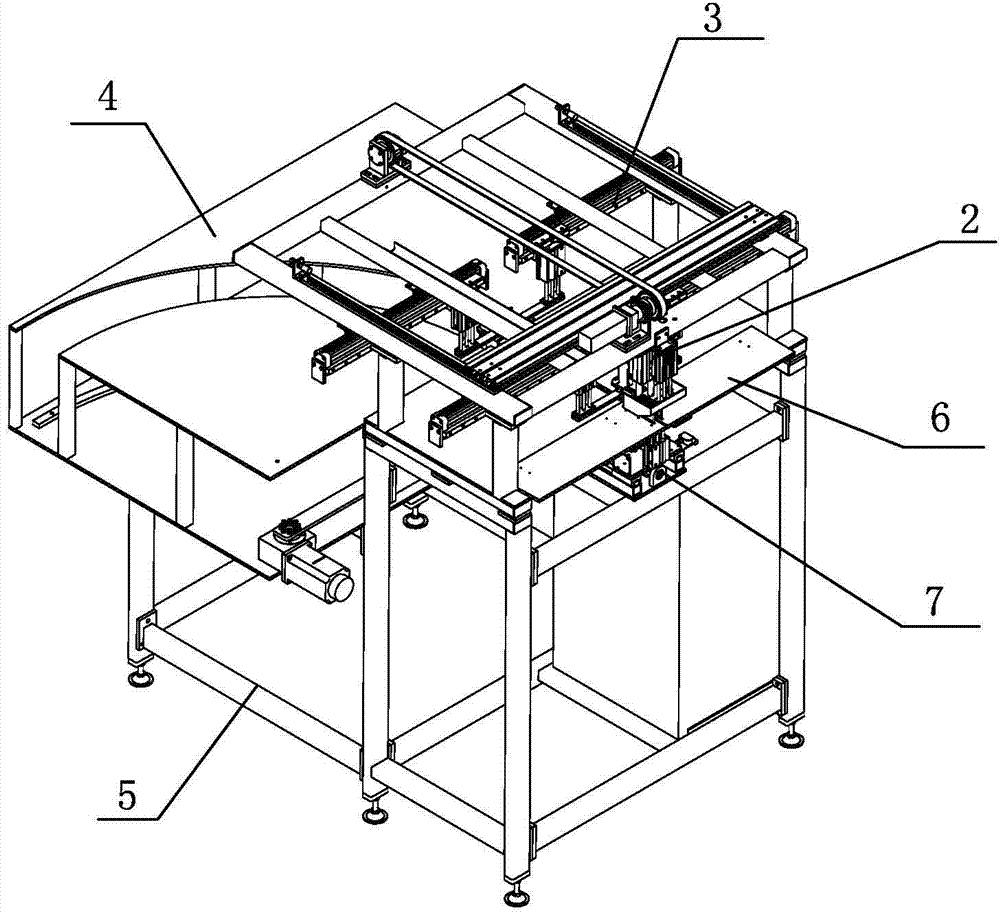

[0027] Such as figure 1 , figure 2 As shown, the flax splitting machine of the present invention is characterized in that it includes a feeding conveyor belt that continuously feeds flax 1, a material shifting device that pushes the flax backwards, and a receiving device that pushes the flax The splitting device 2 for dividing the flax into single bundles and the discharging device 4 for sending out the single bundle of flax; the feeding conveyor belt is located at the forefront, the beam splitting device is located at the back of the feeding conveyor belt, and the shifting device is located below the beam splitting device , The discharging device is located behind the beam splitting device.

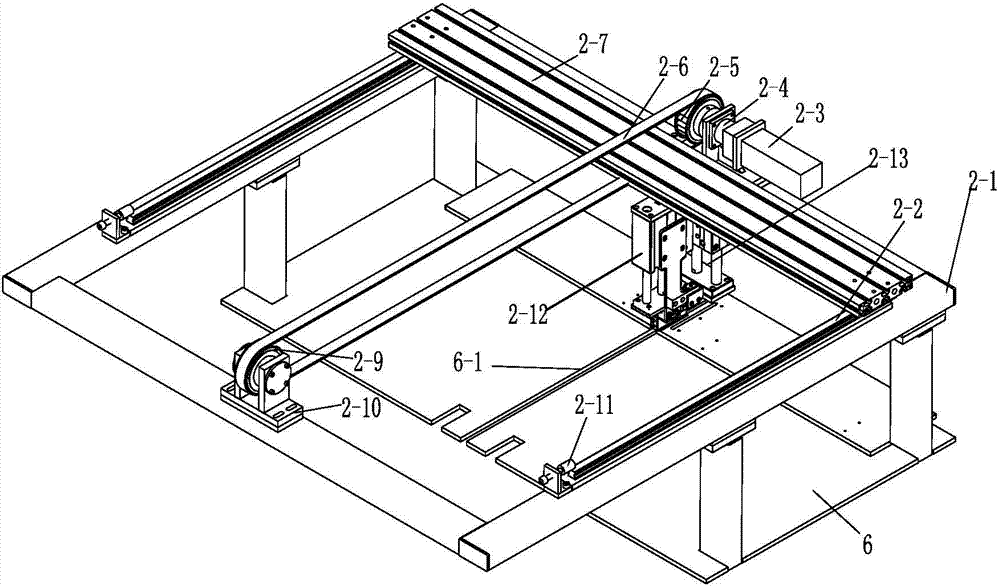

[0028] Such as Figure 3 to Figure 8 As shown, the beam splitting device includes a beam s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com