Yielding anchor cable

An anchor cable and cable body technology, applied in the field of yield anchor cable, can solve the problems of high material ductility requirements, low bearing capacity, non-constant resistance, etc., and achieve the effects of large controllable range, high bearing capacity and stable resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

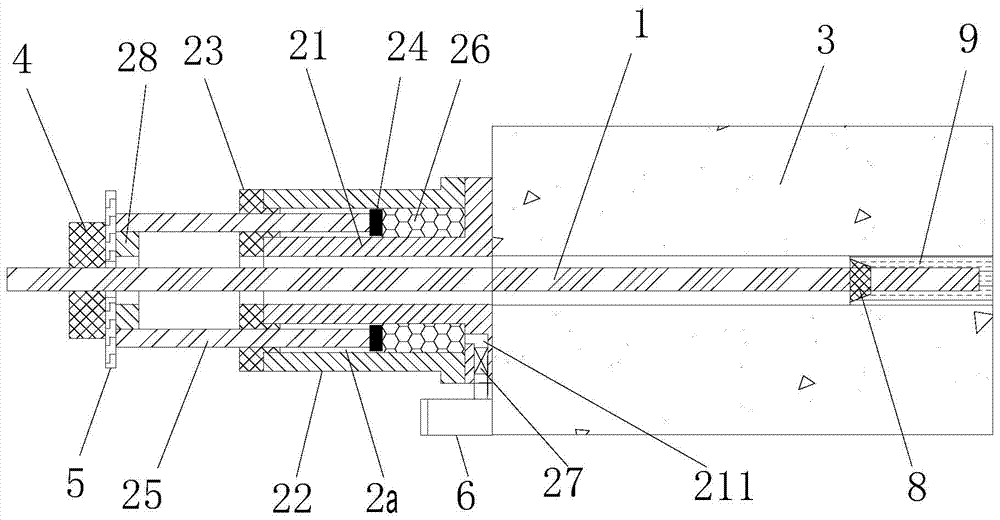

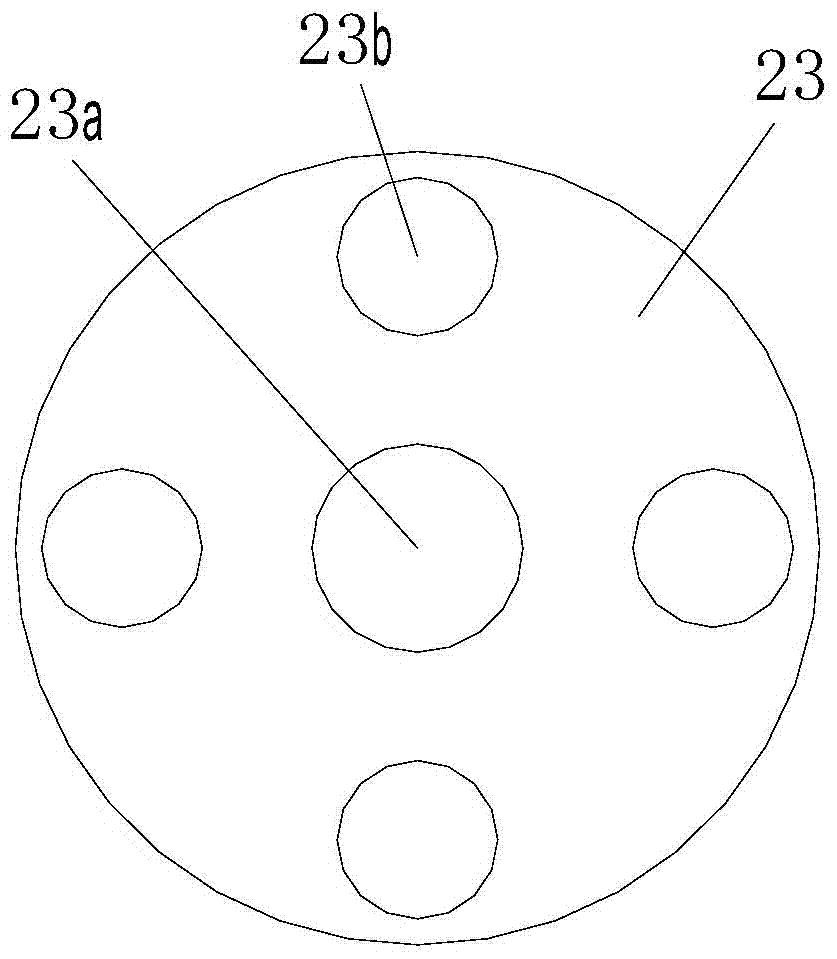

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a top view of the cylinder head of the present invention, as shown in the figure: the yield anchor cable of the present embodiment includes a cable body 1 made of steel strands and a pressure relief mechanism arranged on the cable body 1 for pressure relief. Described letting pressure mechanism is compression cylinder structure and comprises inner cylinder body 21, outer cylinder body 22, cylinder cover 23, piston ring 24 and piston rod 25; Described inner cylinder body 21 is a hollow cylinder body, and described cylinder cover 23 is set There is a central hole 23a and a rod hole 23b matched with the piston rod 25. The cable body 1 passes through the hollow part of the inner cylinder body 21 and the central hole 23a of the cylinder head 23 and is linked with the piston rod 25; the inner cylinder body 21. The outer cylinder body 22 and the cylinder head 23 form a working chamber 2a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com