Movable hot blast heater

A hot stove, mobile technology, applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as trouble, hot stove can not be moved, labor intensity, etc., to achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

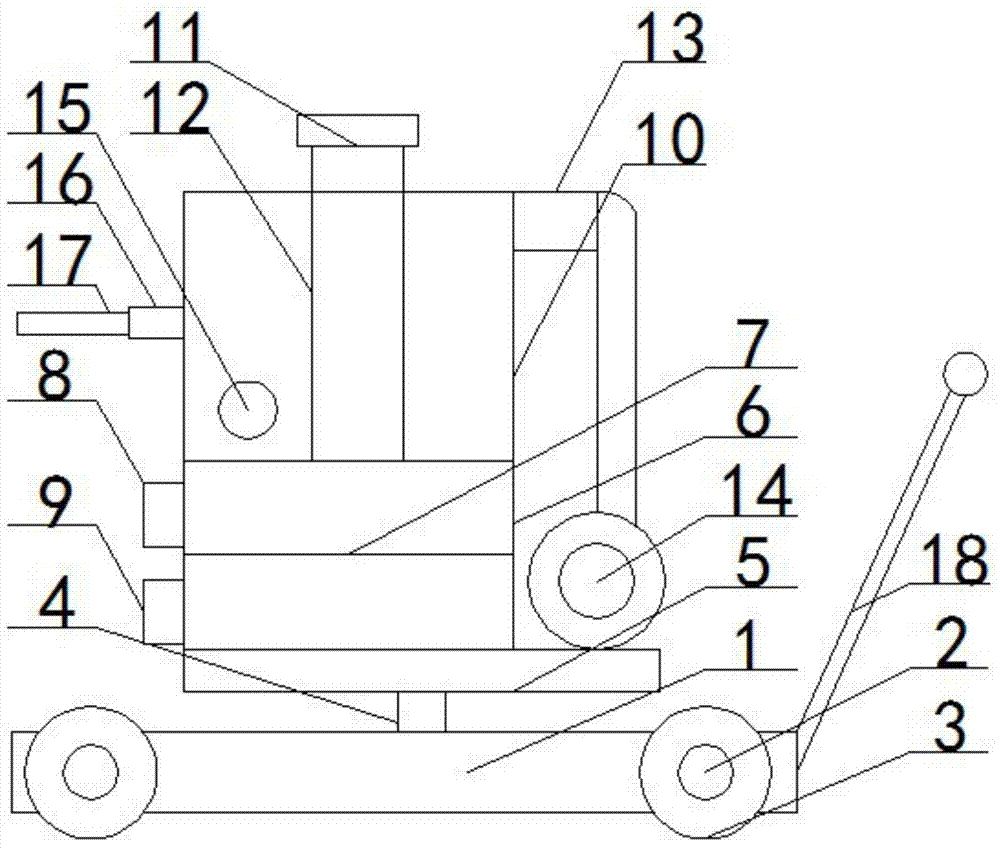

[0010] Such as figure 1 As shown, the present invention discloses a mobile hot blast stove, comprising: a base 1, a roller 2, a roller 3, a rotating shaft 4, a turntable 5, a combustion chamber 6, a metal grid 7, a coal filling port 8, and a slag removal port 9 , heating chamber 10, exhaust pipe 11, heat pipe 12, air inlet pipe 13, cold air blower 14, air outlet pipe 15, rotating sleeve 16, wooden handle 17, handle 18, the front and rear ends of the base 1 pass through The bearings are respectively equipped with a roller 2, the two ends of the roller 2 are respectively fixed with a roller 3, the rotating shaft 4 is vertically installed on the base 1 through the bearing, and the rotating disk 5 is welded on the upper end of the rotating shaft 4 , the combustion chamber 6 is welded on the turntable 4, a metal grid 7 is welded horizontally inside the combustion chamber 6, the coal filling port 8 is welded on the upper part of the combustion chamber 6, and the coal filling port 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com