Automatic clamping pulley inspection machine

A clip-on, inspection machine technology, applied in the mechanical field, can solve the problems of no detection pulley quality, low detection efficiency, poor detection reliability, etc., and achieve the effect of intuitive inspection, good working stability and fast loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

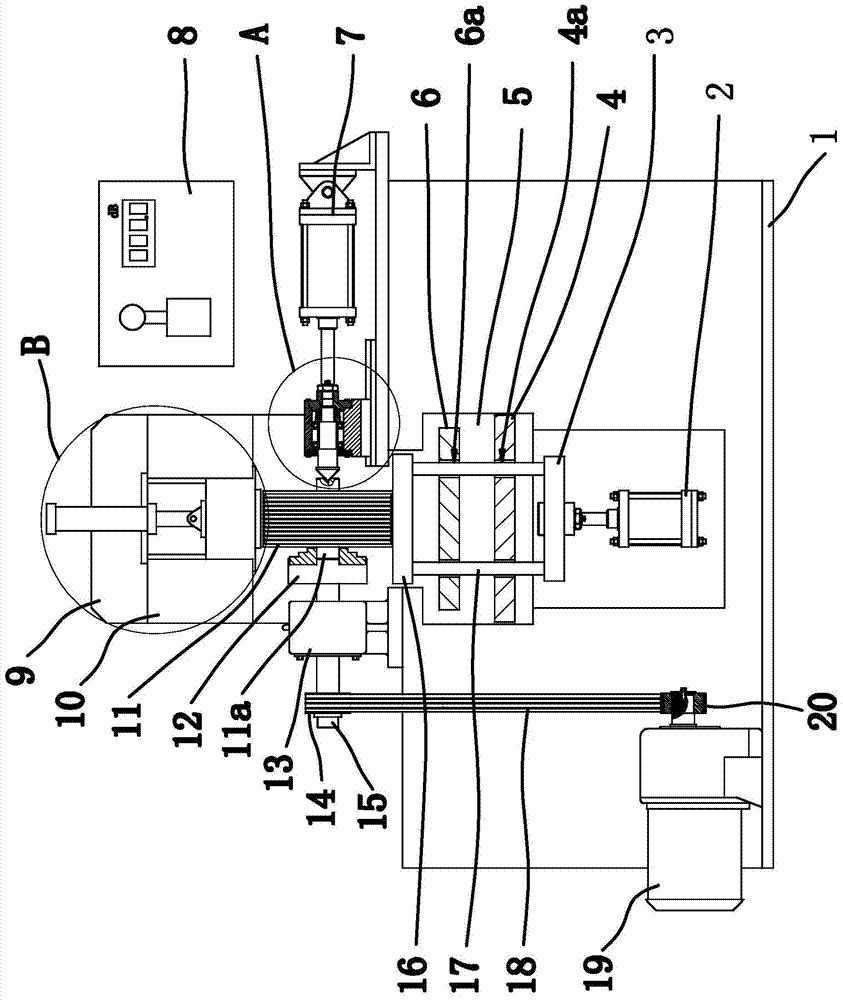

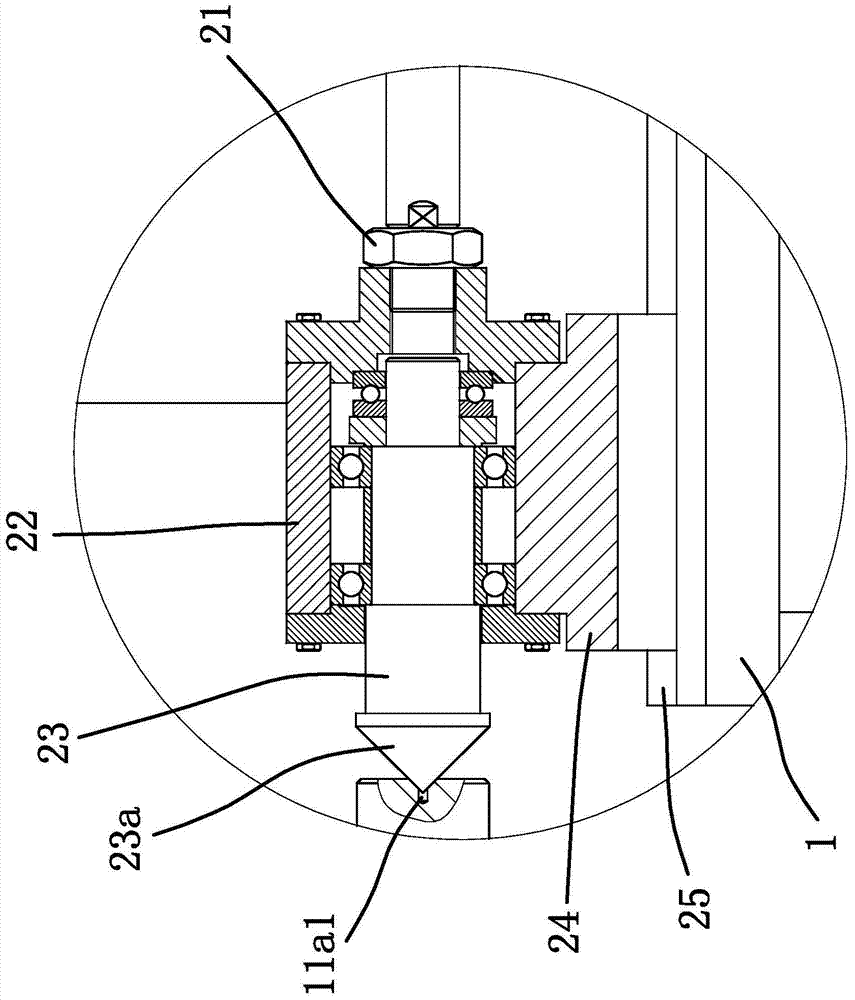

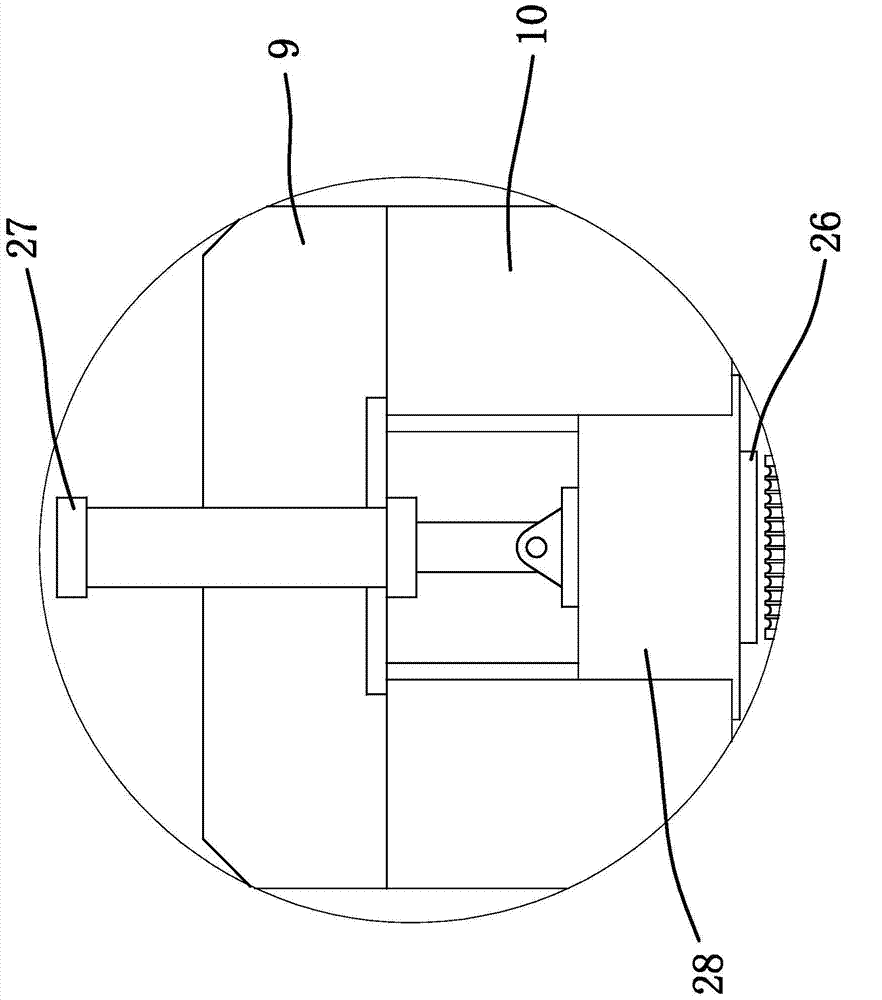

[0038] Such as figure 1 , figure 2As shown, in the automatic clamping pulley inspection machine, the middle part of the pulley 11 has a pulley shaft 11a, and the two ends of the pulley shaft 11a have a central hole 11a1; the automatic clamping pulley inspection machine includes a workbench 1 with a gap in the middle of the workbench 1, A positioning platen 16 is arranged in the gap, and the lower part of the positioning platen 16 is connected with a lower lifting and positioning structure that can drive it up and down and position it; the positioning platen 16 is fixed with a positioning block 29 that is used to contact the pulley 11 wheel surface , the positioning block 29 is fixed on the positioning platen 16 by means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com