Service life prediction method of high-speed numerical control milling machine cutter on basis of state space model

A technology of high-speed CNC milling machine and state space model, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems that cannot be directly observed, and achieve high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

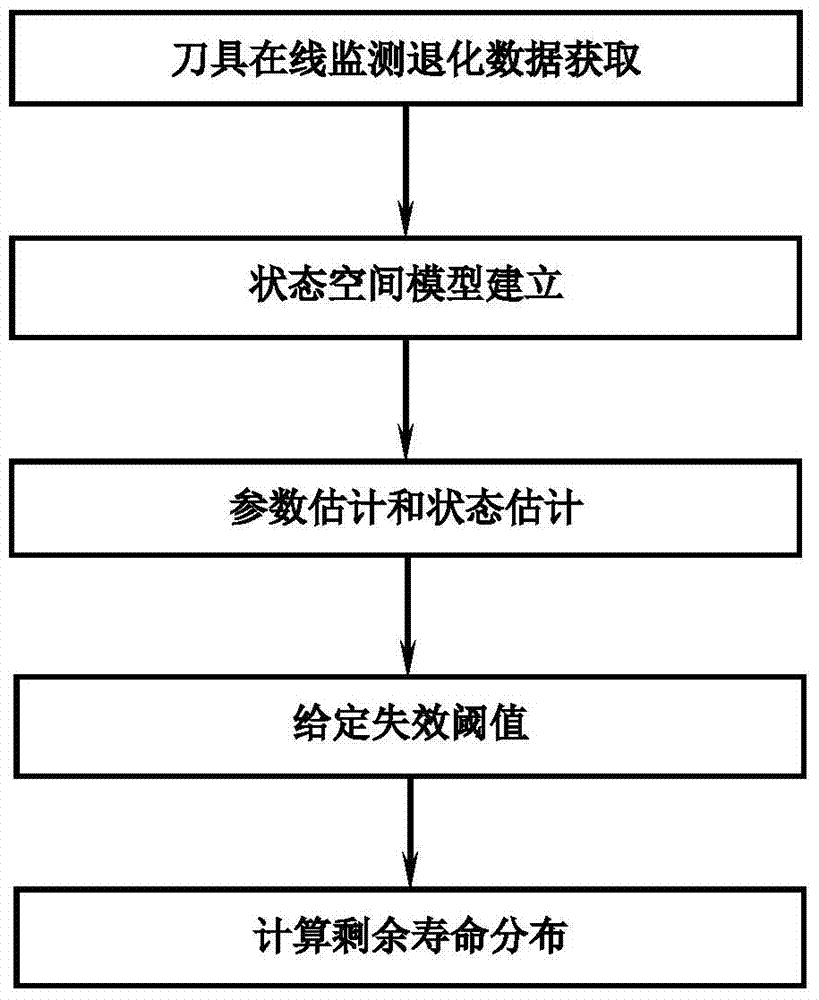

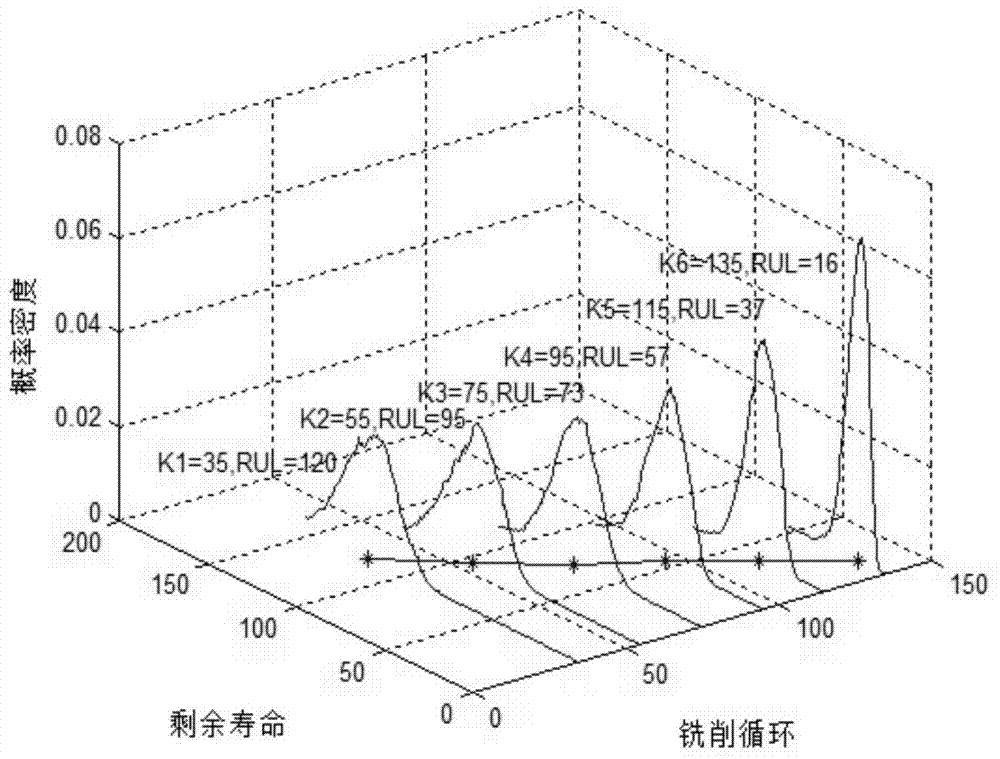

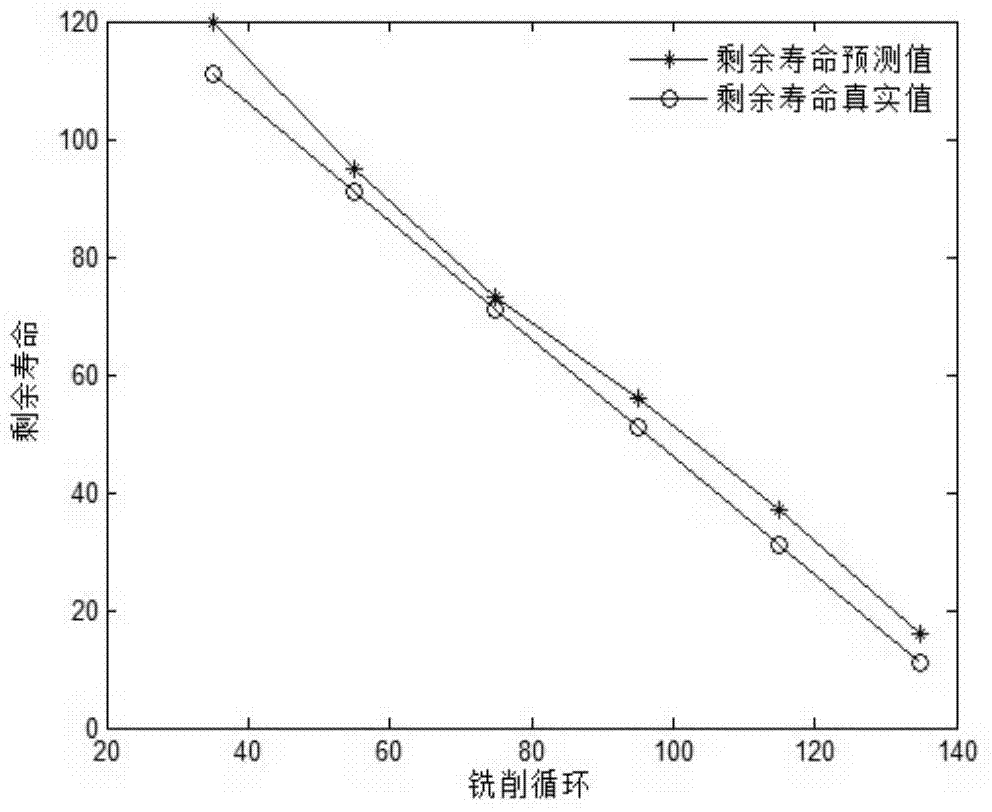

[0021] Now in conjunction with example, accompanying drawing, the present invention is further described: the method for predicting the remaining life of milling machine tools based on online state monitoring comprises the following steps:

[0022] Step 1: According to the structural characteristics of the high-speed CNC milling machine tool, arrange online monitoring equipment and sensing devices to measure the pressure signal, acceleration signal, acoustic emission signal and tool wear signal that can characterize tool degradation. In the example, the tool wear signal is used to estimate; then the collected data is processed to extract the characteristic parameters that can characterize the tool degradation trend. In this example, the root mean square of tool wear is taken as the monitoring time series feature quantity.

[0023] Step 2: Establish the observation equation and the state equation of the state space model according to the relationship between the monitoring sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com