Device for cutting braid electronic component

A technology for electronic components and cutting devices, which is applied in the direction of electrical components, electrical components assembling printed circuits, printed circuits, etc., which can solve the problem that the position of the cutter and electronic components cannot be guaranteed, the electronic components are prone to wear, and the feeding of electronic components is not smooth And other problems, to achieve the effect of good cutting effect, smooth feeding, and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

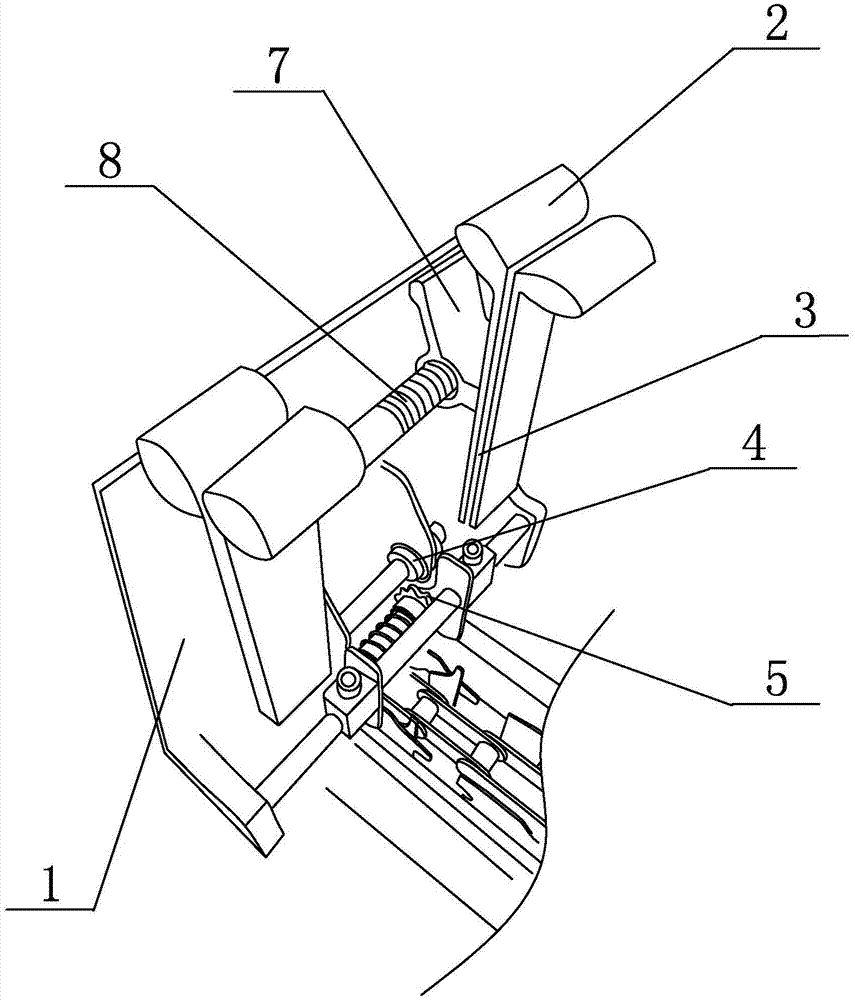

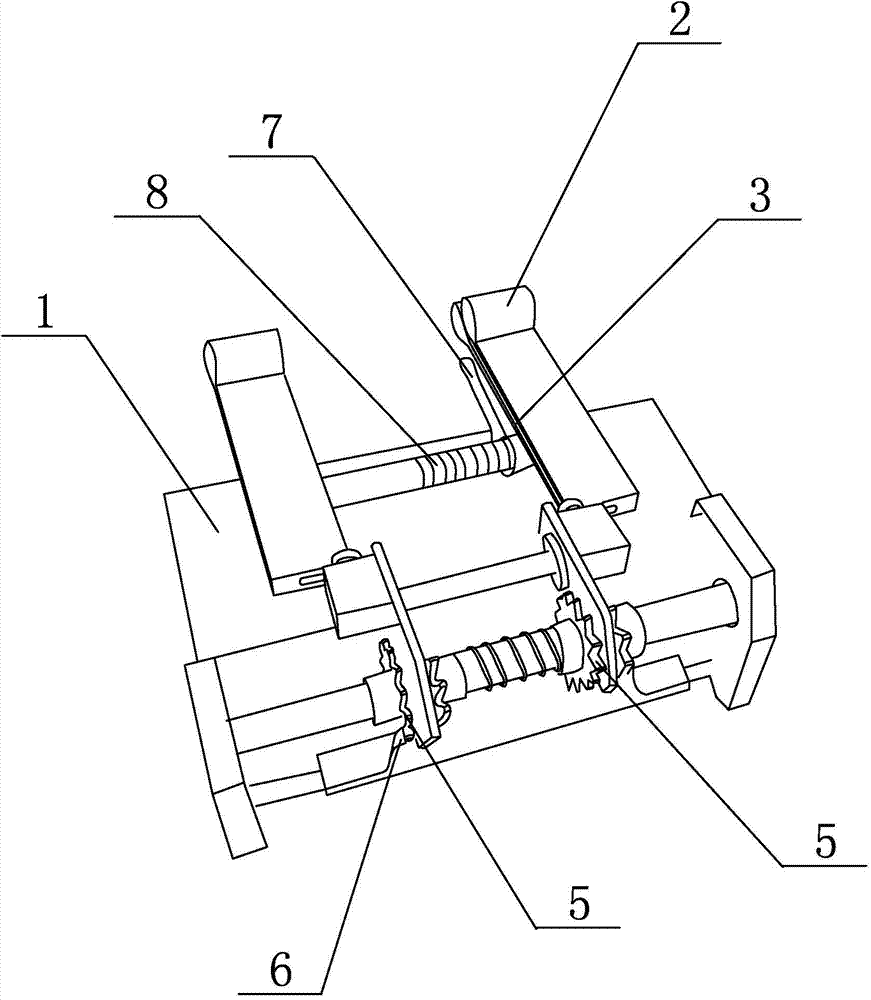

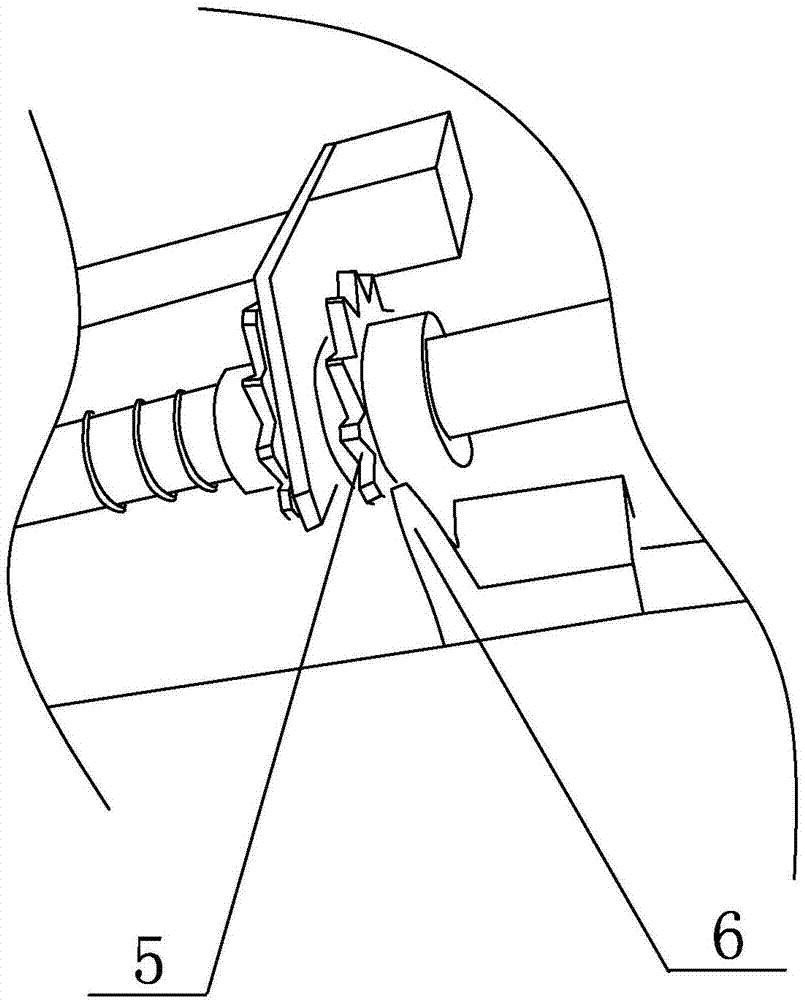

[0016] like figure 1 , figure 2 , image 3 As shown, a cutting device for braiding electronic components according to the present invention includes a fixed seat 1 and a motor erected above the transmission track, and two splints 2 are symmetrically arranged on the fixed seat 1, and the inside of the splint 2 Oppositely, there is an insertion gap 3 that allows the braided electronic components to enter the cutting device. Below the insertion gap 3, there are positioning wheels 4 and transmission teeth 5 fixed on the fixed seat 1, and the motor drives the transmission teeth. 5 rotates, and described positioning wheel 4 is staggeredly arranged on the top of transmission tooth 5, and the outer side of transmission tooth 5 is provided with cutter 6, and positioning wheel 4 assists transmission tooth 5 to make the braiding electronic element between the gear teeth be positioned at cutter 6 Realize cutting.

[0017] The distance between the two splints 2 is adjustable. The splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com