Active energy ray curable offset ink composition

An active energy ray and composition technology, applied in printing, ink, printing device and other directions, can solve the problems of inability to show, low migration performance, insufficient drying, etc., and achieve the effect of low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

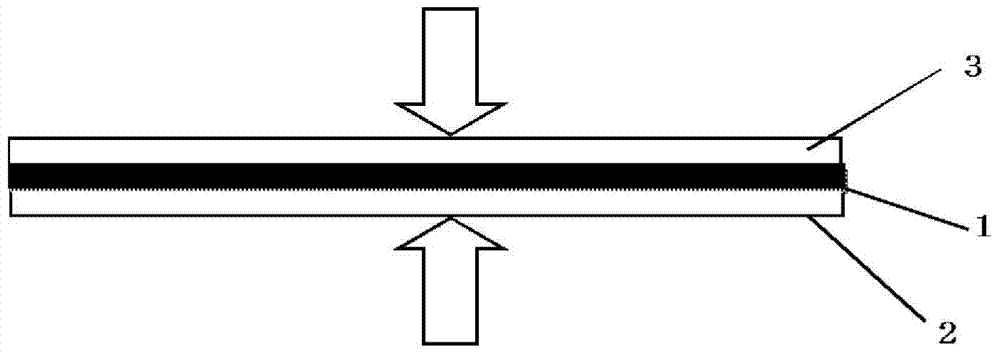

Image

Examples

Embodiment

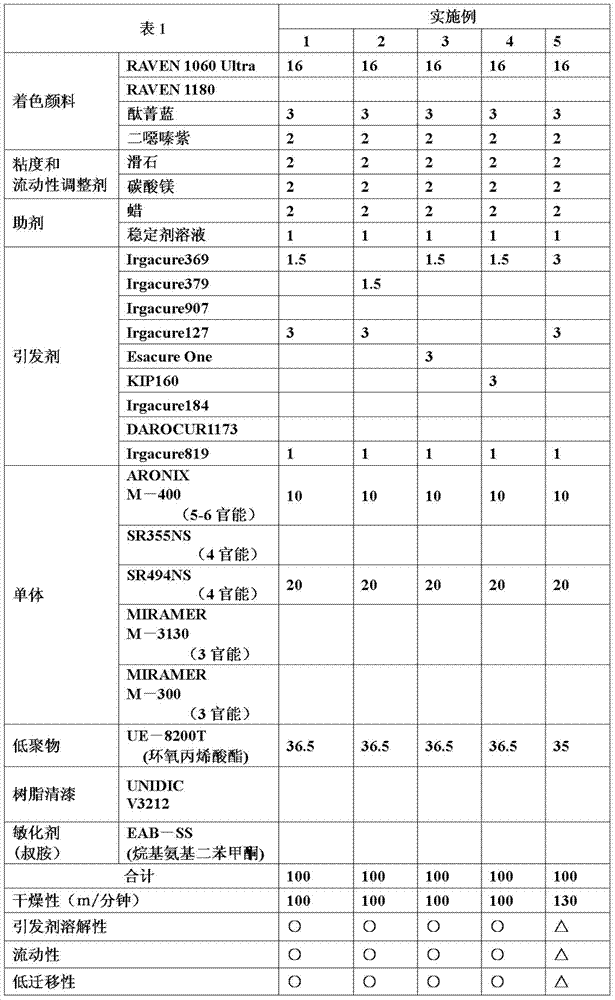

[0044] Hereinafter, the present invention will be specifically described using examples.

[0045] [Manufacturing method of ink composition]

[0046] According to the compositions in Tables 1 to 3, the inks of Examples 1 to 13 and Comparative Examples 1 to 8 were ground with a three-roll mill to obtain various ultraviolet curable ink compositions.

[0047] It should be noted that in all examples, 16% by weight of carbon black as a color material was added (as carbon black, RAVEN 1060 Ultra was used in Examples 1 to 12, and RAVEN 1180 was used in Example 13) and 3% by weight of phthalocyanine blue and 2% by weight of dioxazine violet (21% by weight of color materials) as complementary color components, 2% by weight of talc and 2% by weight of magnesium carbonate as viscosity and flow modifiers (4% by weight in total) ), 2% by weight of wax as other auxiliary agents and stabilizer solution (the mixture of 10% by weight of p-methoxyphenol and 90% by weight of ethylene oxide modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com