Rare earth alloying Al-Cu-Mg-Fe-Ni high-strength and heat-resistance aluminum alloy

An al-cu-mg-fe-ni, rare earth alloy technology, applied in the field of non-ferrous metals, can solve the problems of rare earth Nd, such as no related reports, to improve the mechanical properties at room temperature and high temperature heat resistance, excellent comprehensive performance, strong The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

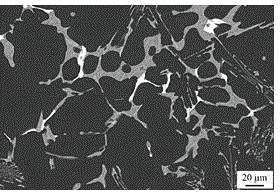

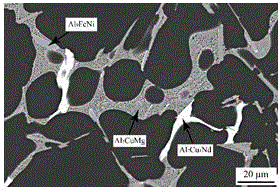

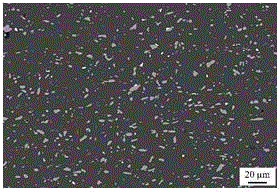

Image

Examples

preparation example Construction

[0014] The preparation methods of the alloys of the examples and comparative examples of the present invention are configured according to the designed alloy components, and the ingots are obtained by smelting in a resistance crucible furnace.

[0015] The mass percent content ranges of each element in the alloy are: Cu 2.6~3.5%, Mg 1.3~1.8%, Fe 0.1~0.8%, Ni 0.1~0.8%, Nd 0.05~0.50%, Mn 0.1~0.25%, Zr 0.1% ~0.25%, and the balance is Al; Fe and Ni elements in the alloy are added in an equal ratio (mass ratio) of 1:1.

Embodiment 1

[0017] The alloy composition is (weight percent): Cu 2.6%, Mg 1.7%, Fe 0.6%, Ni 0.6%, Nd 0.17%, Mn 0.15%, Zr 0.15%, and the balance is Al. The extruded rods were solution treated at 530°C for 1.5 h and then water quenched at room temperature. The quenched samples were immediately aged in an air circulation furnace within 0.5 h to make the alloy reach the peak aging state. The aging system was 195°C× 18 h. The room temperature and high temperature mechanical properties data of the obtained alloy are shown in Table 1.

Embodiment 2

[0019] The alloy composition is (weight percent): Cu 3.0%, Mg 1.65%, Fe 0.80%, Ni 0.80%, Nd 0.20%, Mn 0.15%, Zr 0.15%, and the balance is Al. The extruded rods were solution treated at 535°C for 1 h and then water quenched at room temperature. The quenched samples were immediately aged in an air circulation furnace within 1 h to make the alloy reach the peak aging state. The aging system was 195°C× 20 h. The room temperature and high temperature mechanical properties data of the obtained alloy are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com