Continuous steel-strip degreasing method

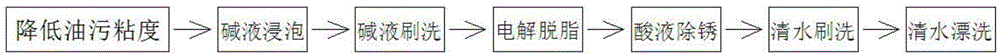

A steel strip and electrolytic degreasing technology, which is applied in the field of steel strip processing, can solve the problems of low continuous degreasing efficiency of steel strips and difficult to achieve steel strips, and achieve the effect of obvious improvement of product quality, improvement of degreasing efficiency and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

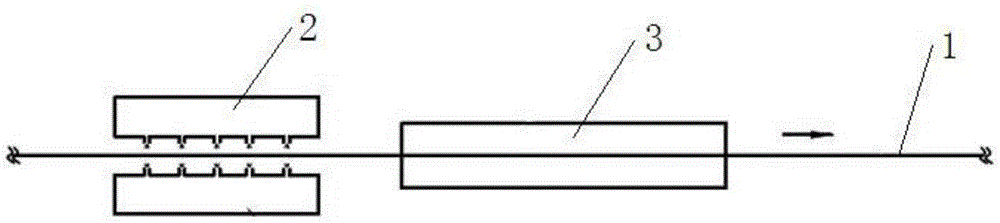

[0020] The steel belt is heated by hot air convection, such as figure 2 As shown: the hot air box 2 for preheating the steel strip 1 is set in front of the steel strip continuous degreasing equipment 3, the steel strip 1 passes through the hot air box 2 and the steel strip continuous degreasing equipment 3 in turn, and the hot air box 2 is set up and down correspondingly, respectively Hot air is sprayed on the upper and lower surfaces of the steel strip 1 to heat the steel strip 1 to 100°C to 120°C, and the heated steel strip 1 enters the steel strip continuous degreasing equipment 3 for degreasing. In this embodiment, hot air is used to preheat the steel strip 1, which has no pollution, high cleanliness and low cost.

Embodiment 2

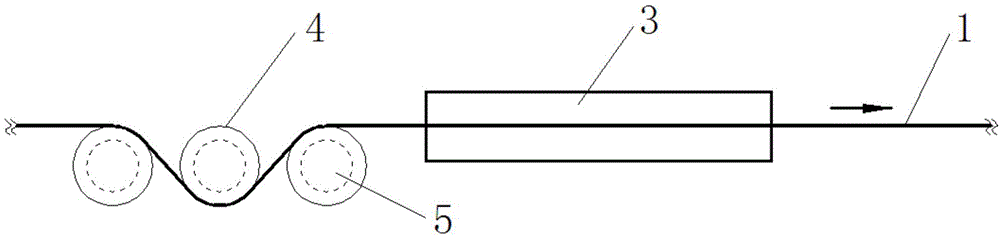

[0022] Using roller contact heating steel belt, such as image 3 Shown: the heating roller 4 used for preheating the steel strip 1 is set in front of the steel strip continuous degreasing equipment 3, there are several sets of heating rollers 4, the steel strip 1 is wound on each heating roller 4 in turn, and the heating roller 4 passes through the set The heating source 5 in the roller raises the temperature of the steel strip 1 to 120° C. to 150° C., and the heated steel strip 1 enters the steel strip continuous degreasing equipment 3 for degreasing. It should be noted that the heating source 5 in this embodiment can be hot exhaust gas, air, or other electric or gas heating devices.

Embodiment 3

[0024] The steel strip is heated by electromagnetic induction, such as Figure 4 As shown: the electromagnetic induction heater 6 for preheating the steel strip 1 is set before the continuous strip degreasing equipment 3, and the steel strip 1 passes through the electromagnetic induction heater 6 and the continuous strip degreasing equipment 3 successively, and the electromagnetic induction heater 6. The steel strip 1 is heated to 110° C. to 140° C., and the heated steel strip 1 enters the steel strip continuous degreasing equipment 3 for degreasing. In this embodiment, an electromagnetic induction coil is used to preheat the steel strip 1 , which has high heating efficiency and is hygienic and clean, and will not have adverse effects on the subsequent degreasing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com