Non-supported insect-resistant flooring

A supported, keelless technology, used in pest control measures, local raised floors, building components, etc., can solve the problems of insect repellants easily dispersed in the air, affecting installation operations, and poor insect control effects, saving wood. , easy operation, high support strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

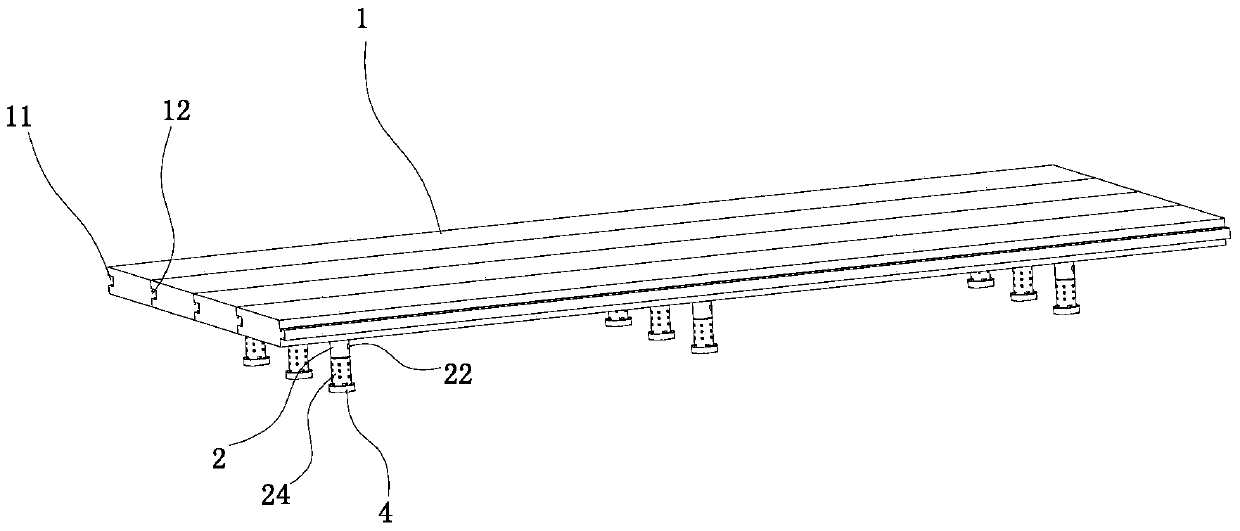

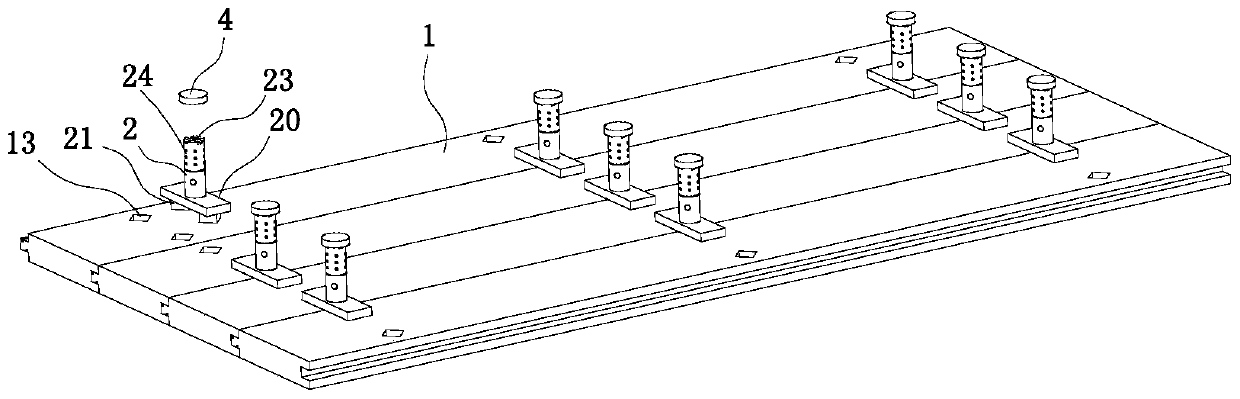

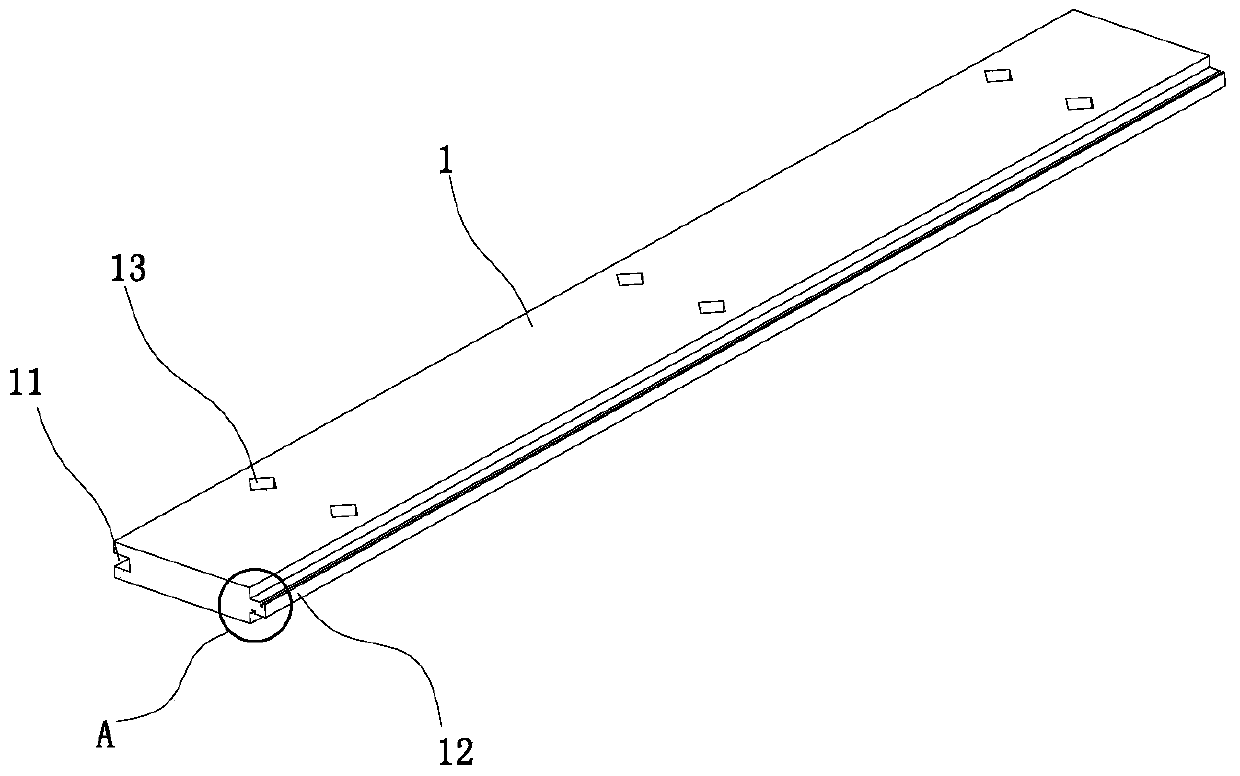

[0026] Such as figure 1 ,Such as figure 2 As shown, the non-keel support type insect-proof floor of this embodiment includes a floor body 1, and the lateral sides of the floor body 1 have convex strips 11 and grooves 12, and the adjacent floor bodies 1 pass through the convex strips 11 and the grooves. 12, it also includes a support column 2 installed under the floor body 1. The upper end of the support column 2 has a support block 20, and the support block 20 has a mounting groove 13 on the lower surface of the adjacent floor body 1. Protrusion 21, also has radial through-hole 22 on the supporting column 2; The lower end of supporting column 2 is screw-mounted column 24, and insect repellant is placed in the central cavity of column 24, and the side wall of column 24 has ventilation hole 241 . The columns 24 are evenly distributed bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com