Construction technology of point-type glass curtain wall with stable glass panel connection

A glass panel and glass curtain wall technology, which is applied to the processing of walls, building materials, and building components, can solve the problems of insufficient close fit, easy to cause danger, and unstable connection between glass panels and connecting parts, etc., to achieve installation Convenient and fast, easy installation and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

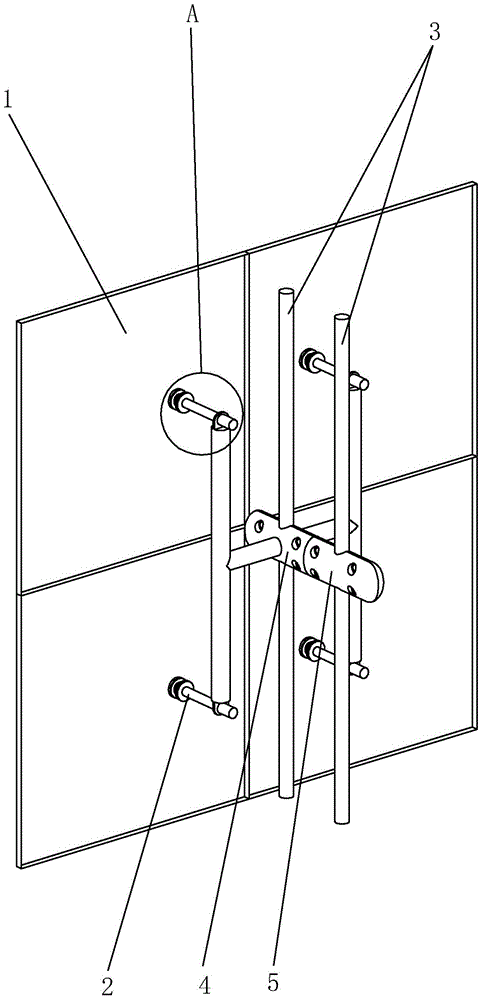

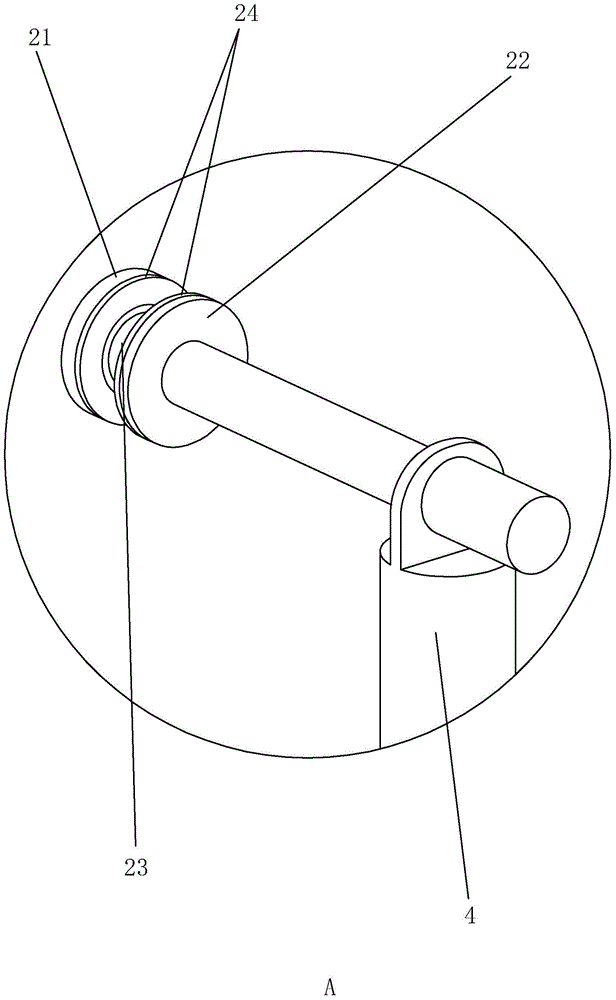

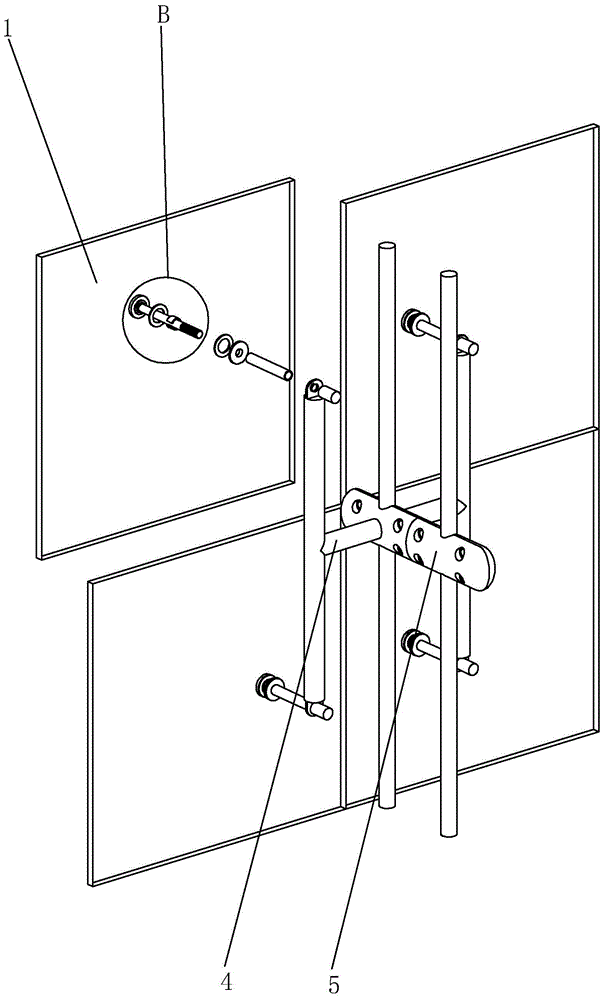

[0026] The embodiment of the construction process of the point-type glass curtain wall with stable connection of glass panels of the present invention will be further described with reference to the accompanying drawings.

[0027] A construction process for a point-type glass curtain wall in which glass panels 1 are connected stably, comprising the following process steps: processing of materials and installation of a point-type glass curtain wall;

[0028] The processing of the material includes the processing of the glass panel 1. The specific steps are: the cutting machine cuts the glass panel 1, and then the glass panel 1 is drilled, that is, the fixing hole is processed, and then the glass panel 1 is tempered and heat-preserved. Afterwards, the glass panel 1 is mechanically ground and chamfered, and then laminated;

[0029] The material processing also includes the processing of the connecting assembly 2 used to fix the glass panel 1 and the connecting piece, and the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com