Dedusting device for down-hole hammer drilling machine

A technology of dust removal device and down-the-hole hammer, which is applied in construction and other directions, and can solve problems such as polluting the environment, affecting the power of internal combustion engines, and damaging human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

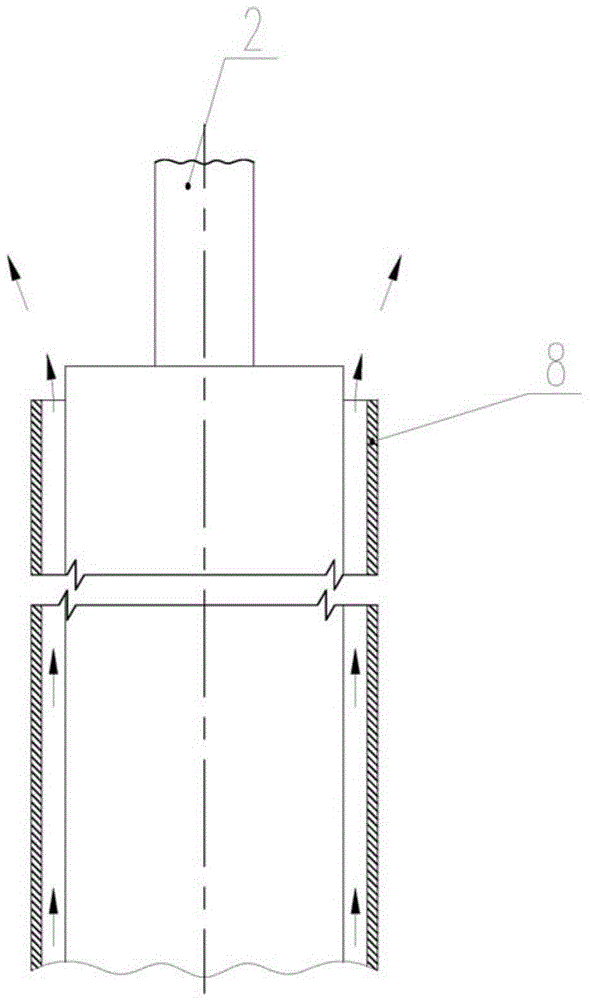

[0016] see figure 1 At present, during the working process of the down-the-hole hammer drilling rig, the airflow carrying rock powder and sludge moves upwards from the annular gap between the drill pipe 2 and the casing 8, and finally directly discharges into the air at the casing 8 orifice.

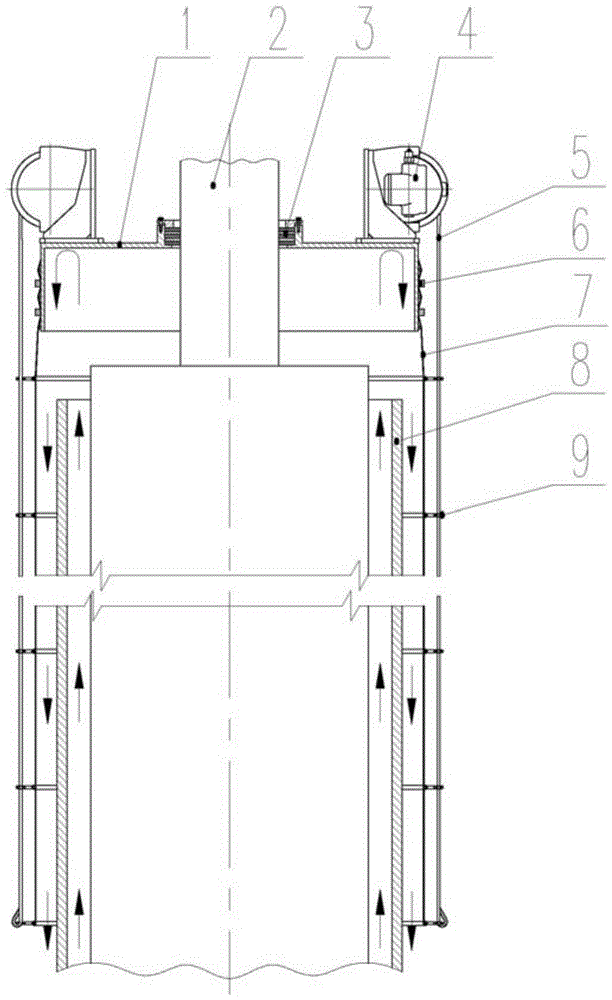

[0017] see figure 2 , the dust removal device for down-the-hole hammer drilling rigs provided by the present invention includes a circular top cover 1, the circular top cover 1 is provided with a sealing ring 3 assembled with the drill pipe 2, and the sealing ring 3 can be replaced with different specifications to adapt to different diameters A hoist 4 is installed on the round top cover 1, and the upper end of a cylindrical cord 7 that can cover the casing 8 is bundled and installed on the round top cover 1, and the cylindrical cord 7 is axially spaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com