Oil injector sealing gasket of internal combustion engine

A fuel injector and gasket technology, applied in the direction of engine sealing device, machine/engine, fuel injection device, etc., can solve the misalignment between the nozzle gasket and the center of the fuel injector, increase the maintenance cost, and the plane sealing effect Easy to fail and other problems, to achieve good sealing effect and reliability, ensure assembly and work reliability, improve positioning and sealing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

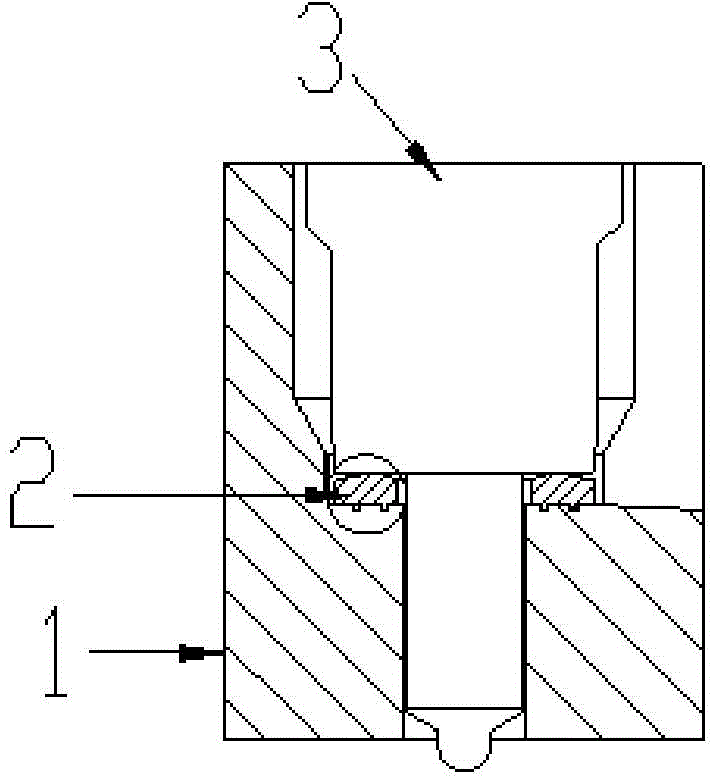

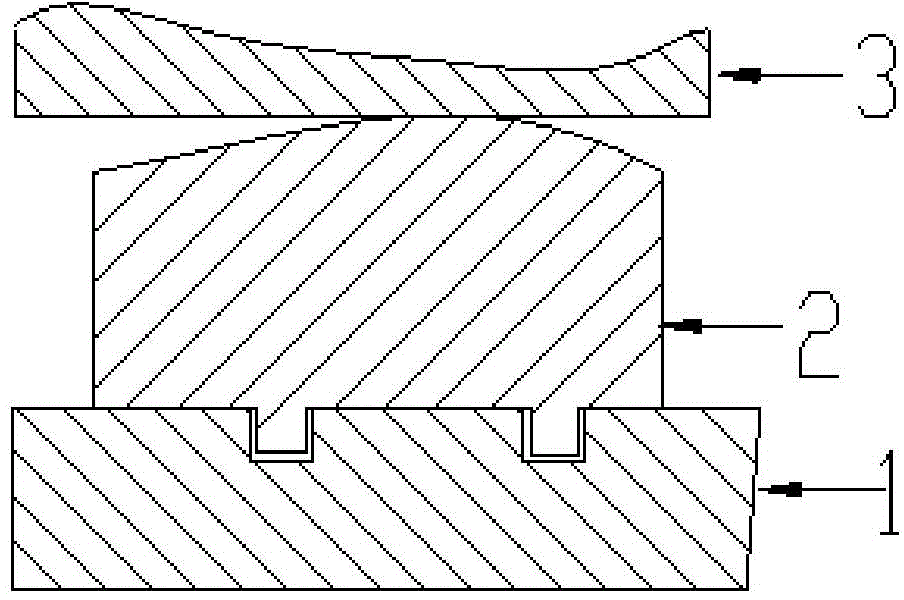

[0024] A fuel injector gasket 2 of an internal combustion engine, the lower surface of the fuel injector gasket 2 has two annular protrusions, the lower surface of the fuel injector gasket 2 is in contact with a cylinder head 3, and the plane of the cylinder head 3 has two annular grooves, Cooperate with the protrusion of the fuel injector gasket 2; the upper surface of the fuel injector gasket 2 is arched and contacts the fuel injector 1.

[0025] The height of the annular groove of the cylinder head 3 and the protrusion of the injector gasket 2 is 2mm, and the width of the groove and the protrusion is 1.5mm. Before the pre-tightening force is applied, the matching clearance between the groove of the cylinder head 3 and the protrusion height and radial direction of the injector gasket 2 is 0.1mm. The fuel injector gasket 2 on the contacting side of the fuel injector 1 is planarly designed with an arched protrusion, and the height of the arched protrusion is 0.3mm. The fuel i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com