Manual-operated screw type kinetic energy generation device

A manual screw and screw technology, which is applied in the direction of machines/engines, mechanical power generation by physical force, and mechanisms that generate mechanical power, can solve the problems of high cost, need of space, and inability to popularize, and achieve low cost, environmental protection, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] With regard to the structure and composition of the present invention, as well as the functions and advantages that can be produced, a preferred embodiment of the present invention will be described in detail as follows in conjunction with the accompanying drawings.

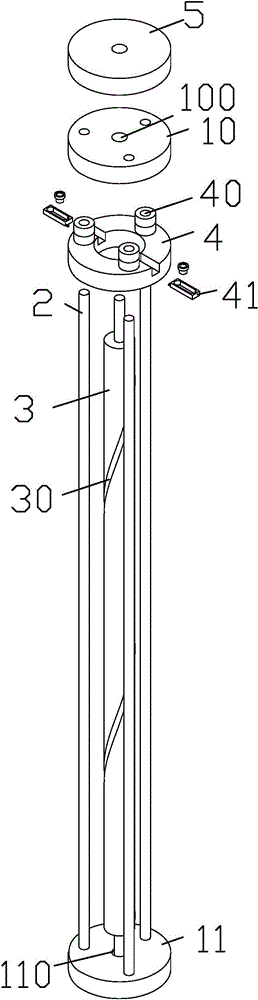

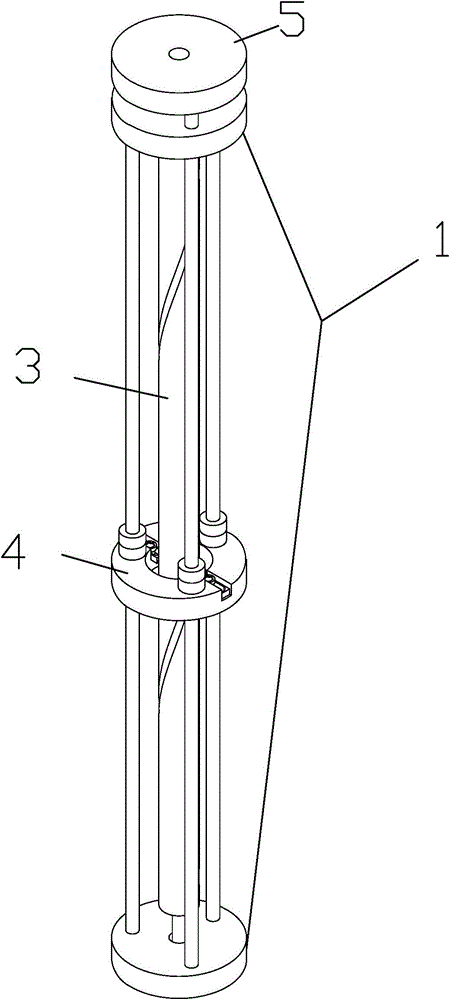

[0027] Please refer to Figure 1 to Figure 3 Shown, show manual screw type kinetic energy production device of the present invention, comprise following element:

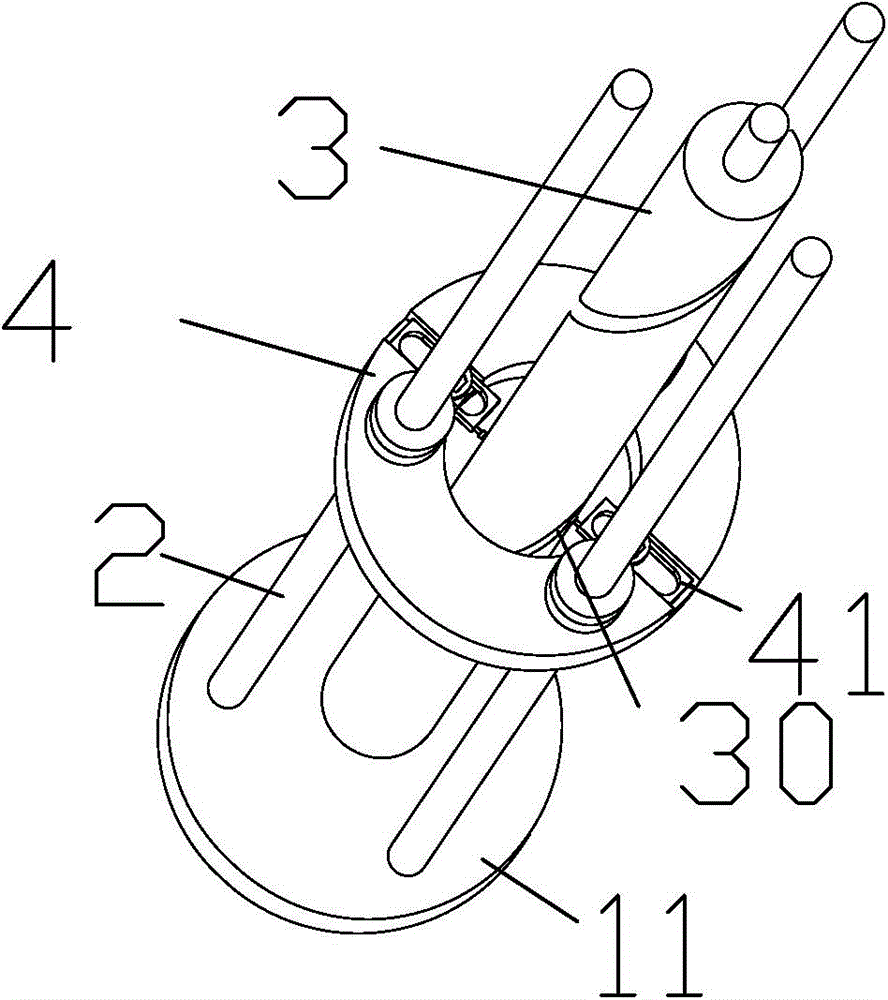

[0028] A body 1 is divided into an upper seat 10 and a lower seat 11 . A through hole 100 is defined in the middle of the upper seat 10 . A concave hole 110 is disposed in the middle of the lower seat 11 .

[0029] At least two guide rods 2, preferably three guide rods 2, are fixedly connected between the upper base 10 and the lower base 11, forming a triangle shape.

[0030] A screw 3 is located between the at least three guide rods 2 . The upper end of the screw rod 3 is rotatably connected with the upper base 10 and extends out of the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com