Shock absorber for energy recovery by converting mechanical energy into electric energy and recovery method thereof

An energy recovery and mechanical energy technology, applied in shock absorbers, springs/shock absorbers, mechanisms that generate mechanical power, etc., can solve the problems of short service life of shock absorbers, low energy utilization rate, etc. The effect of strong impact resistance and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

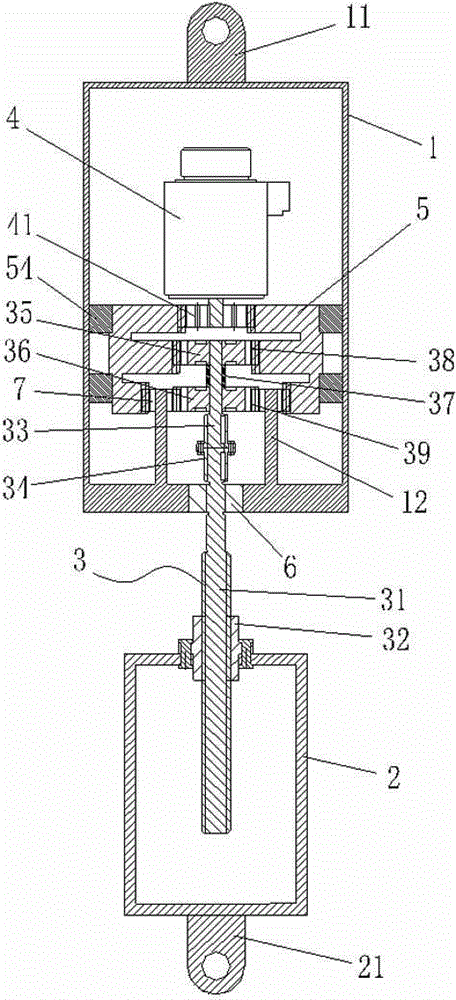

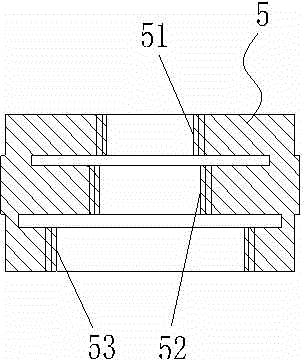

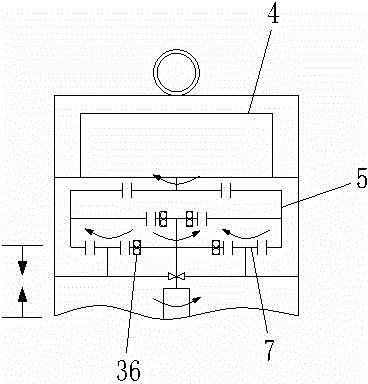

[0029] Embodiment one: if Figure 1~2 As shown, an energy recovery shock absorber that converts mechanical energy into electrical energy includes an upper box body 1 and a lower box body 2, and a ball screw pair 3 is arranged in the middle of the top of the lower box body 2, and the ball screw pair 3 includes The nut 32 fixed on the top of the lower box body 2, the screw rod and the ball in the nut are set. In order to avoid excessive torque, the screw rod is composed of a connecting rod 33 and a screw shaft 31, and the connecting rod 33 is connected with the overrunning clutch. , the screw shaft 31 is matched with the nut 32, the connecting rod 33 and the screw shaft 31 are connected through a coupling 34, and the top of the connecting rod 33 is provided with a reversely installed top overrunning clutch 35, a bottom Overrunning clutches 36, top center gears 38 and bottom center gears 39 are set on the outer walls of the two overrunning clutches, a generator 4 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com