Improved swing disc reducer

A reducer and improved technology, applied in mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the complex processing technology of cycloidal gear tooth profile, the gear surface is easily worn, and the noise of the reduction gear increases, etc. problems, to achieve the effect of improving mechanical transmission efficiency, improving product accuracy, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

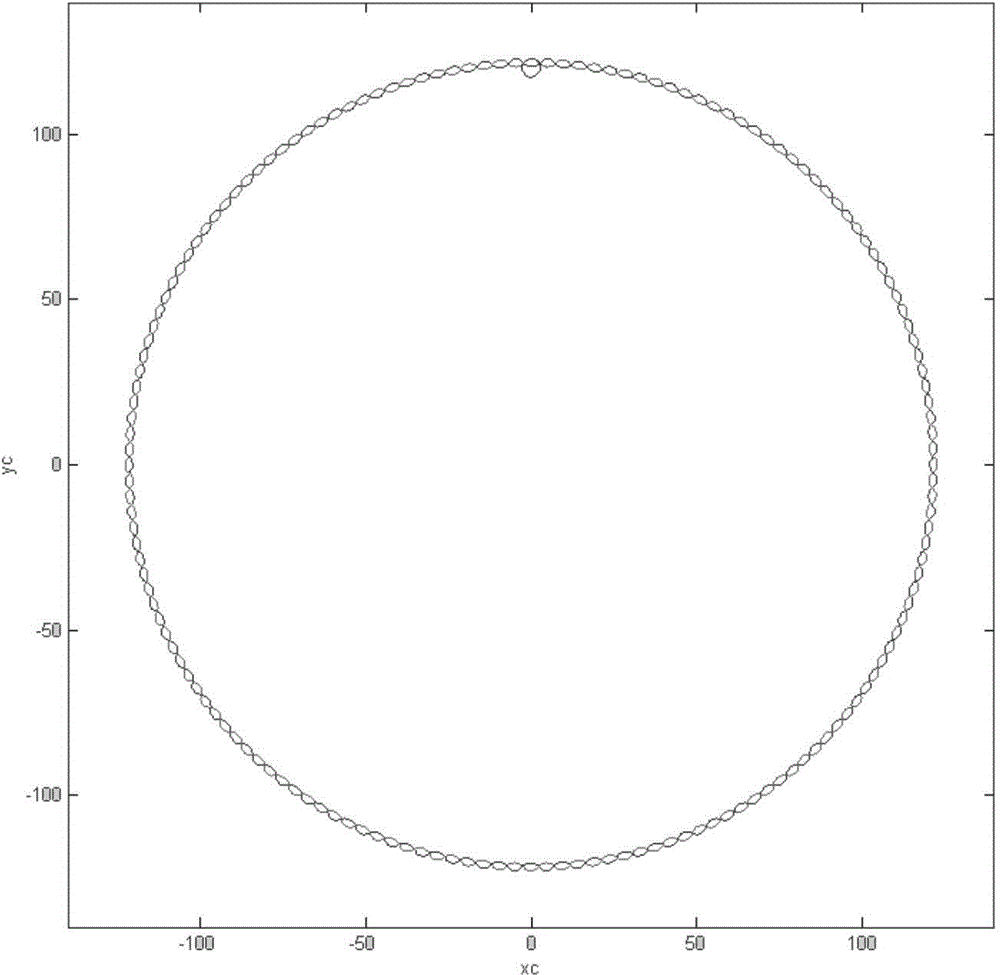

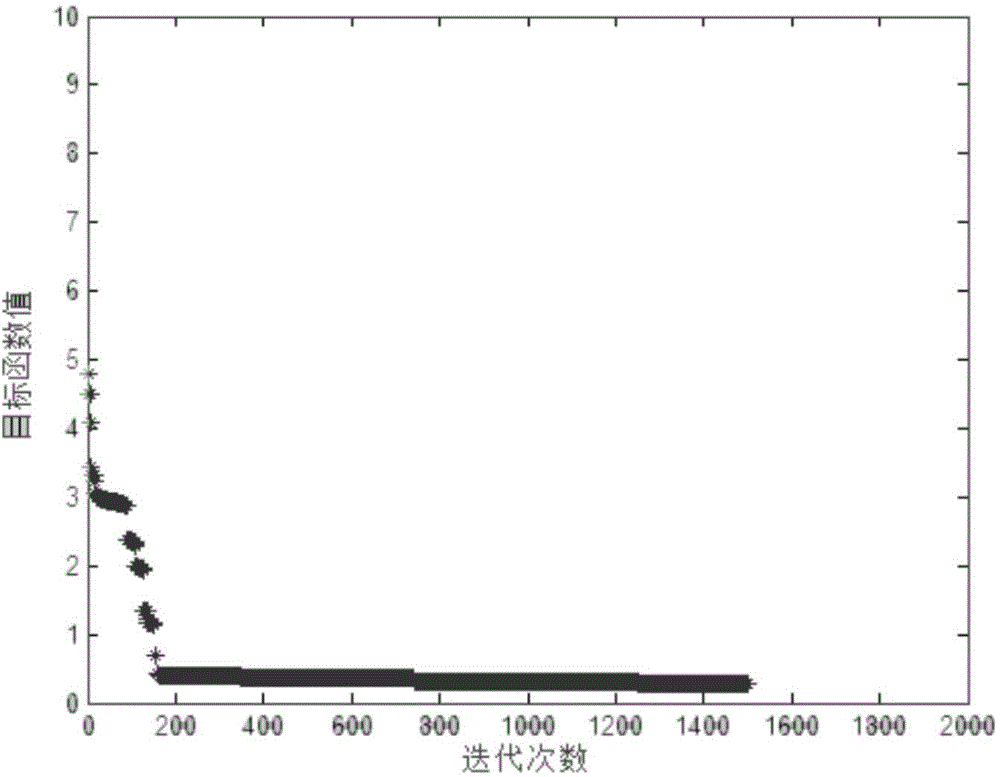

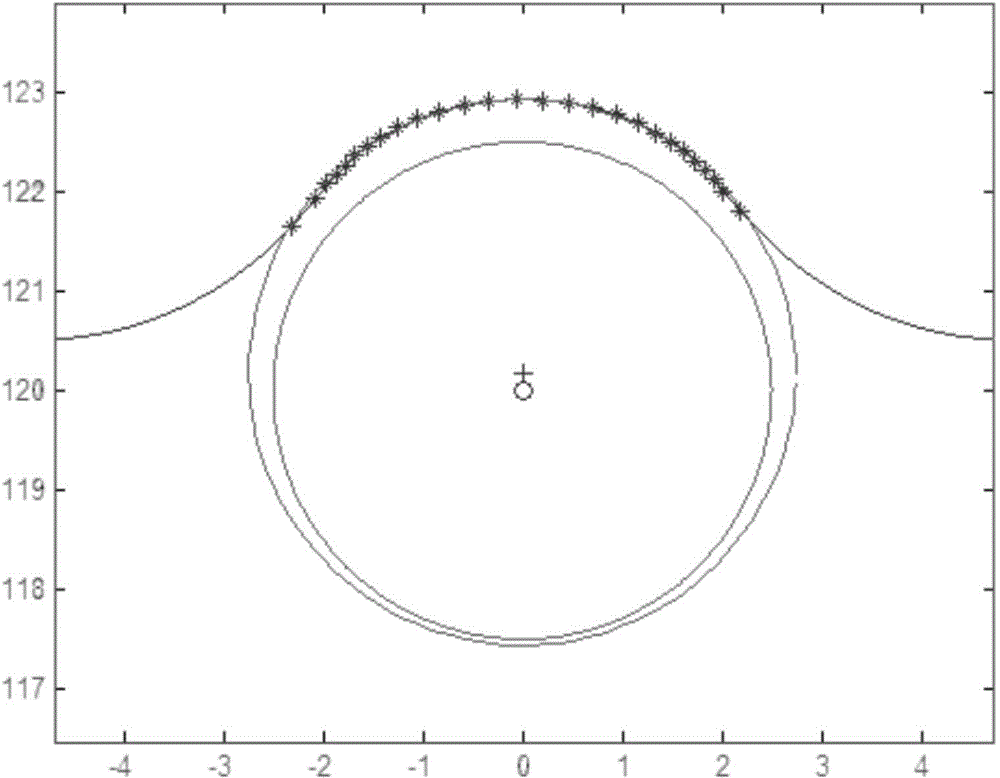

[0041] refer to Figure 1-Figure 6 , an improved wobble reducer provided by the present invention includes a housing 101, an input shaft 102 and an output shaft. The input shaft 102 outputs the power of the motor, and after being decelerated by the improved wobble reducer, the power is output by the output shaft.

[0042] The improved wobble reducer also includes an input mechanism, a reduction mechanism and an output mechanism. The reduction mechanism includes a first inner needle roller 104 , a first toothed disc 105 and an outer needle roller 131 . A plurality of outer needle rollers 131 are arranged circumferentially along the inner wall of the housing 101 . The first toothed disc 105 is rotatably disposed in the housing 101 , and the edge of the first toothed disc 105 is provided with a plurality of first grooves 106 along the circumferential direction, and the first grooves 106 are arranged at equal intervals. The first inner needle roller 104 is embedded in the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com