Detachable flexible water-proof casing pipe device

A casing device, flexible waterproof technology, applied in the direction of pipes, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of difficult disassembly and assembly of pipes, inability to resist earthquakes, damage, etc., to reduce construction costs and practicability. Strong, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

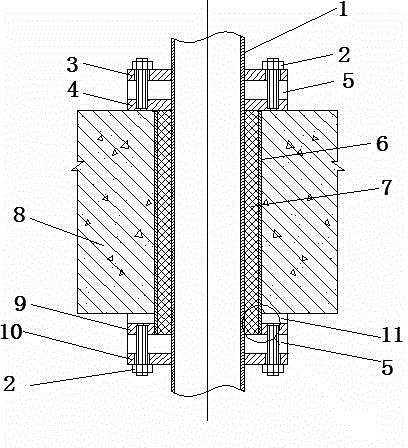

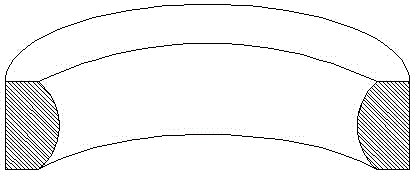

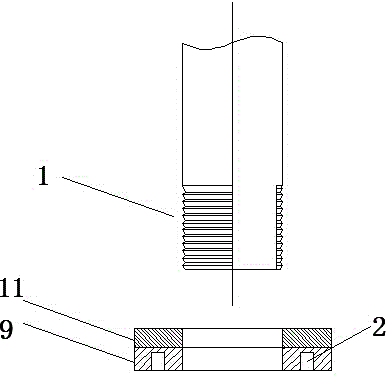

[0012] In the figure, the detachable flexible waterproof sleeve device of the present invention is mainly composed of inner tube 1, screw 2, upper flange 3, lower flange 4, waterproof rubber ring 5, sealing sleeve 6, polymer filler 7, wall 8. A flange with internal thread 9, a lower flange 10, and a shock-absorbing rubber ring 11 are composed.

[0013] The inner pipe 1 and the lower flange 10 are connected by threads, the lower flange 10 and the flange 9 with internal threads are connected by screws 2, the flange 9 with internal threads is connected with the sealing sleeve 6, and the sealing A polymer filler 7 is arranged inside the sleeve 6, the lower flange 4 is fixedly connected to the sealing sleeve 6, and the lower flange 4 and the upper flange 3 are connected by screws. The lower end of the inner tube 1 is provided with threads, and the central hole of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com