Condensing hot water boiler

A hot water boiler and condensing heat exchanger technology, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem that the exhaust gas temperature of condensing hot water boilers cannot be significantly reduced, and the structural design of condensing hot water boilers is not good. Reasonable, heat circulation water loss and other issues, to achieve the effect of lowering the temperature, automatic control, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

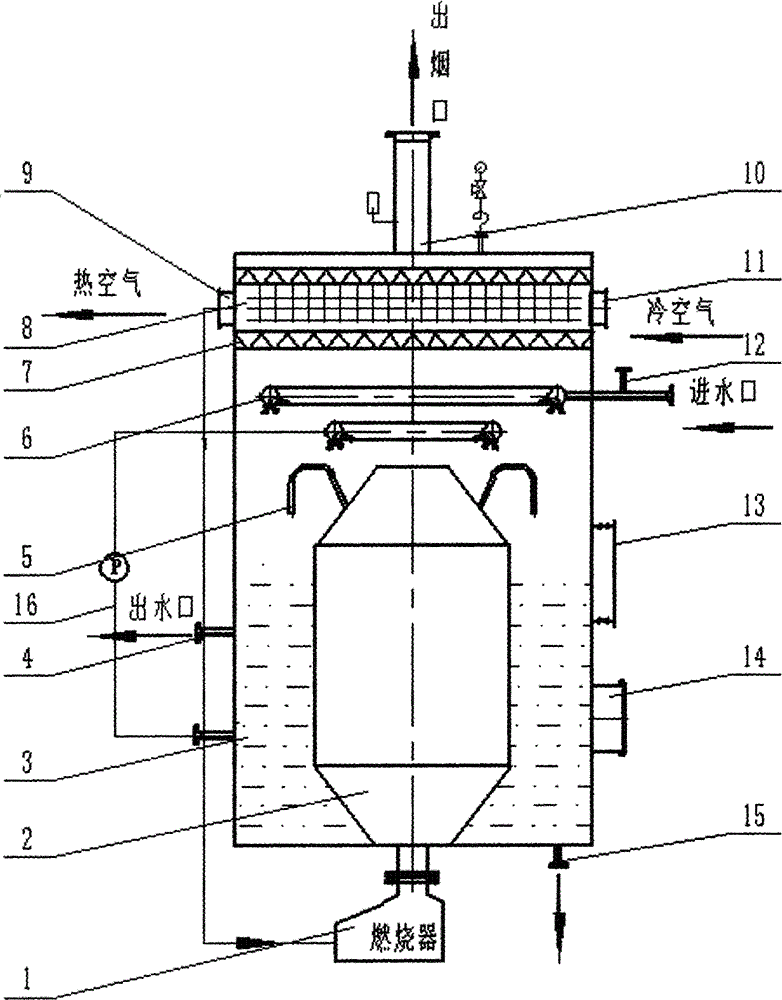

[0018] like figure 1 Shown, the vertical condensing hot water boiler provided by the present invention. It includes a cylindrical combustion chamber 2 and a condensation heat exchanger 3. The cylindrical combustion chamber 2 is placed in the casing of the condensation heat exchanger 3. There is a connecting pipe at the lower end of the cylindrical combustion chamber 2, and the connecting pipe passes through the The casing of the condensing heat exchanger 3 is used to connect with the burner 1; the top cylinder wall of the cylindrical combustion chamber 2 is provided with a smoke outlet, and a smoke guide elbow 5 is connected to the smoke outlet; The center of the top of the condensing heat exchanger 3 is provided with a smoke outlet 10, and a two-stage or multi-stage condensation dehydration device 7 is arranged between the lower part of the smoke outlet and the combustion chamber, and a tubular air preheating device is arranged between the condensation dehydration devices of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com