Yield enhancement (YE) on-line detection management and control method

A detection tube and detection station technology, applied in the direction of semiconductor/solid-state device testing/measurement, etc., can solve the problems of product skipping, low product priority, limited production capacity, etc., and achieve the effect of improving detection efficiency and reducing defect risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

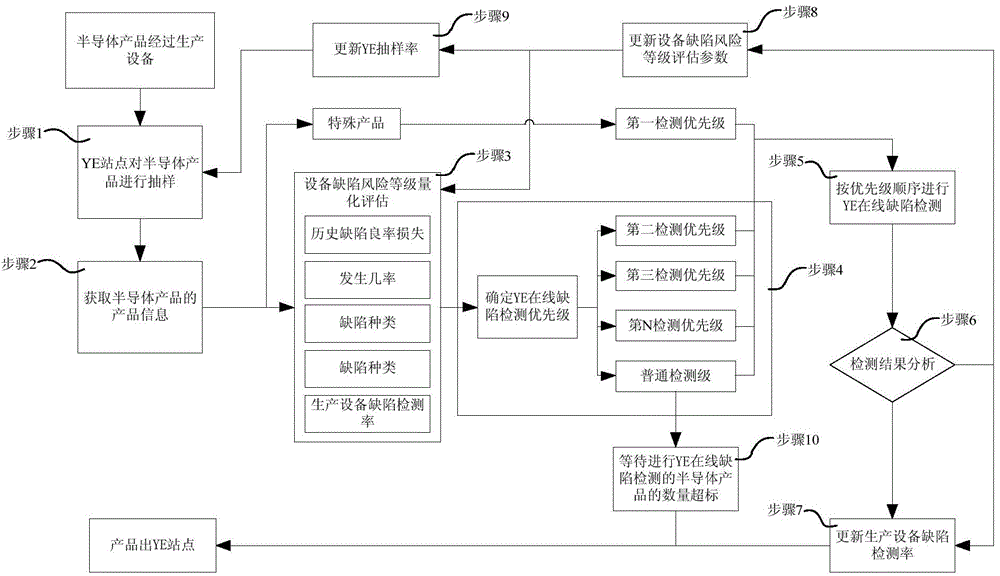

[0035] The main core idea of the present invention is to determine the equipment defect risk level according to the production equipment characteristics and historical defect statistics, and according to the equipment defect risk level, combined with YE online defect detection, determine the YE sampling rate and YE online defect detection priority to achieve optimization The purpose of defect detection sampling in YE online defect detection is to improve the detection efficiency of YE online detection machines and reduce the defect risk of production machines.

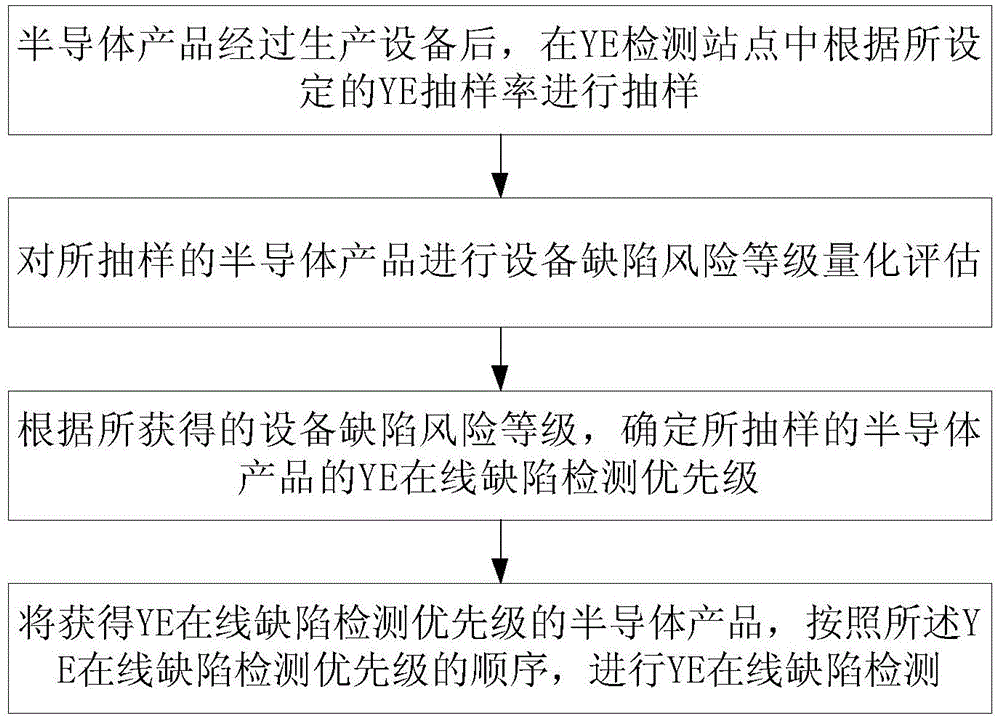

[0036] According to this idea, if figure 1 As shown, the YE online detection and control method embodiment of the present invention includes:

[0037] After semiconductor products pass th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com