Conductive structure and manufacturing method thereof, array substrate, display device

A technology of a conductive structure and a manufacturing method, applied in the field of display devices, conductive structures and manufacturing methods thereof, and array substrates, capable of solving problems such as small protrusions affecting optical inspection of signal line contact conditions, and reducing continuous lengths and small protrusions The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

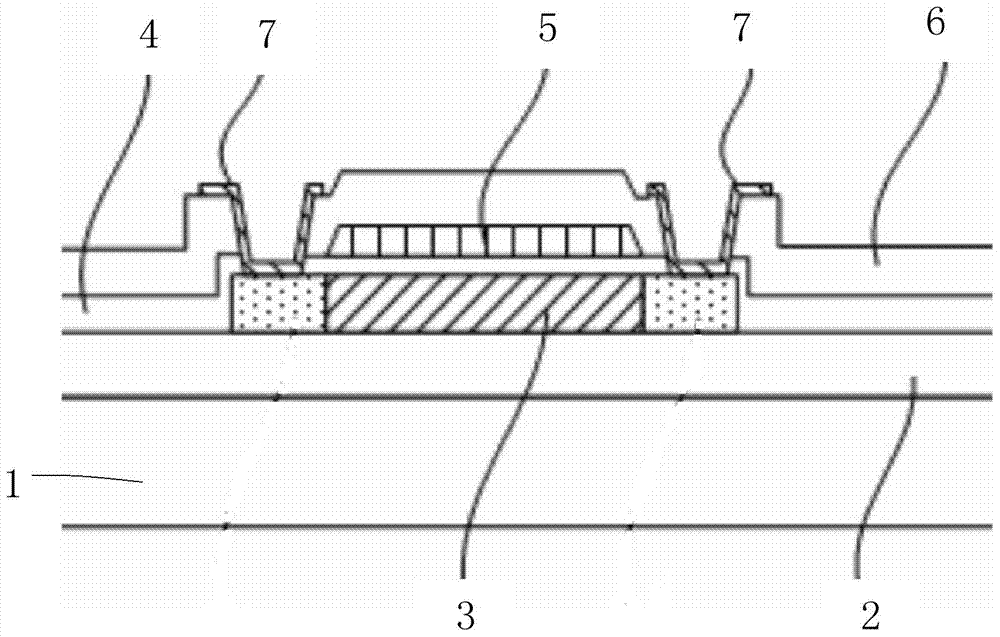

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

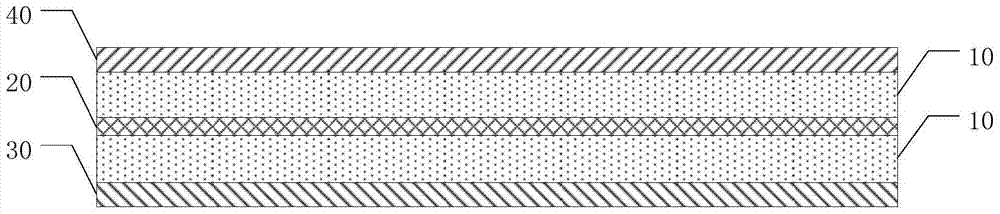

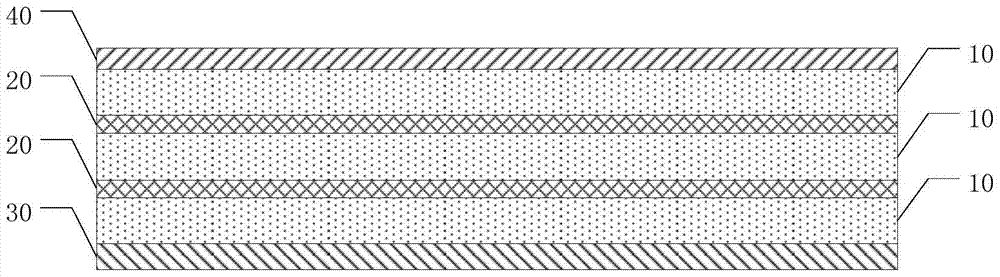

[0025] An embodiment of the present invention provides a conductive structure, the conductive structure includes multiple layers of first metal layers made of aluminum, and a second metal layer is provided between every two adjacent first metal layers, the The second metal layer is made of a metal other than aluminum.

[0026] In the conductive structure provided by the embodiment of the present invention, multiple layers of first metal layers made of aluminum are arranged, and a second metal layer is arranged between every two adjacent first metal layers for barrier, so that the single-layer first metal layer can be reduced. The continuous length of crystal grains in a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com