Cable fixing method and device at connecting position of cable shaft well and cable tunnel

A technology for cable tunnels and cable shafts, applied in the field of fixed devices, can solve the problems of prolonged construction time, thicker cable diameters, and large height differences of cable tunnels, so as to improve the convenience, safety and reliability of construction and improve safety and reliability. , Solve the effect of inconvenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the fixed medium is an elongated fixed medium with a square cross section as an example to describe the following, wherein the fixed medium may be a long strip tube with a square cross section.

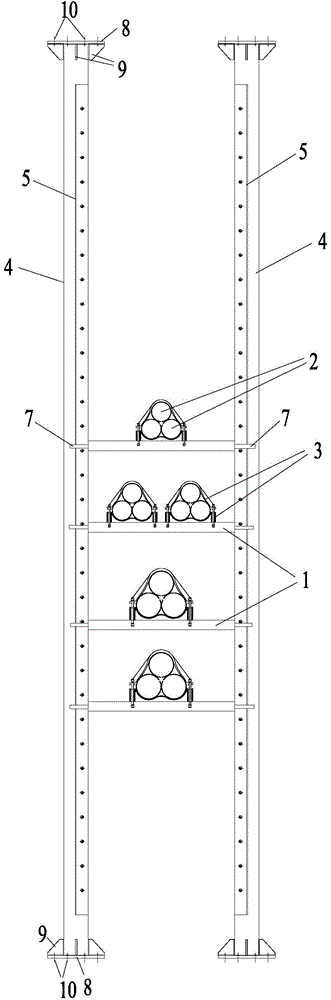

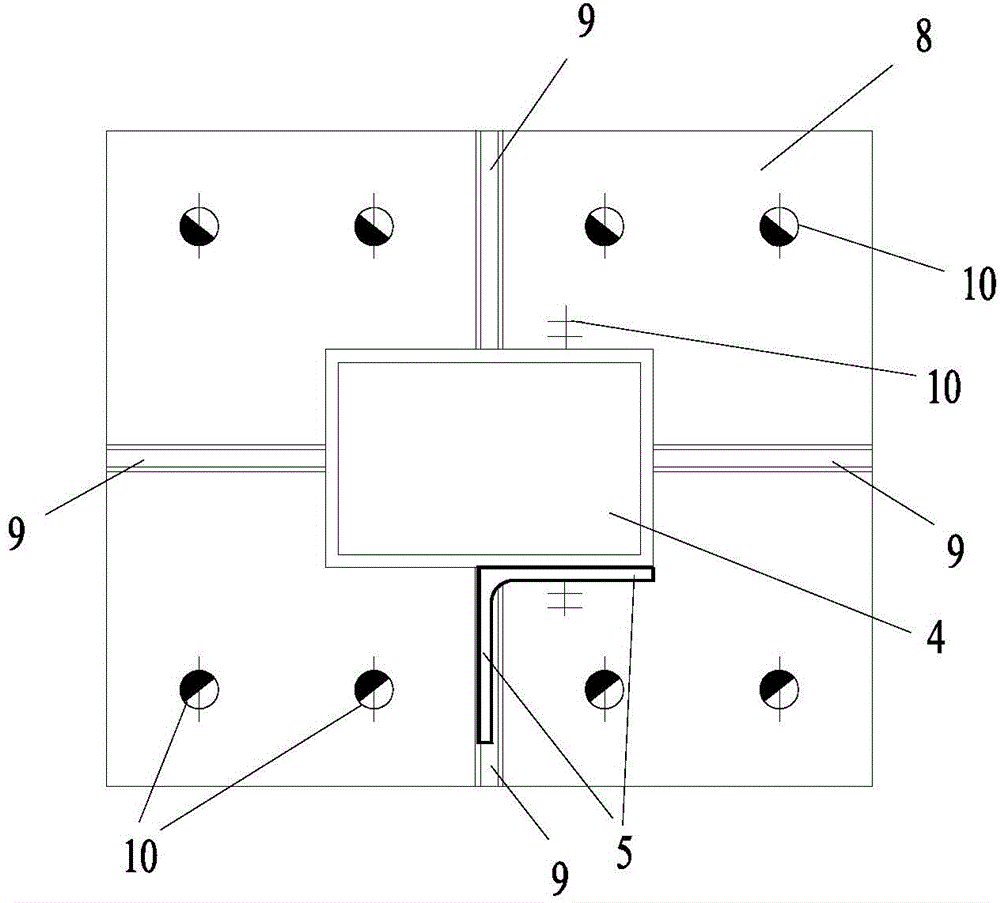

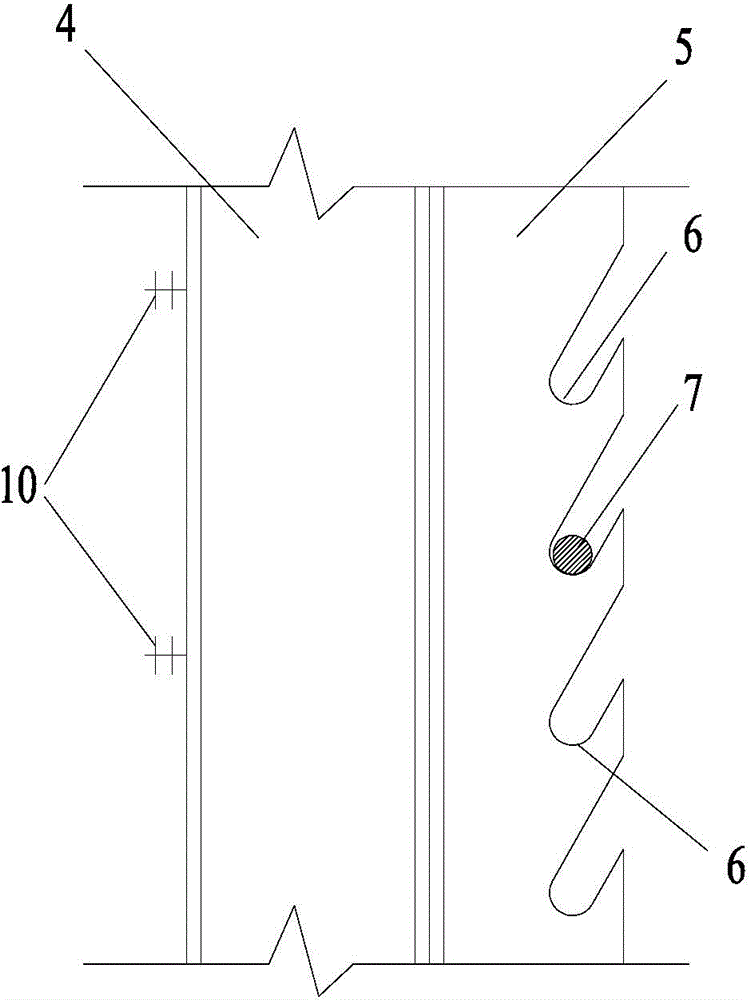

[0036] like Figure 1 to Figure 3As shown, the cable fixing method at the junction of the cable shaft and the cable tunnel of the present invention, at first, the cable 2 is passed through the cable shaft and the cable tunnel in turn, and at this time, the placement plane of the cable 2 is inclined at an angle θ with the horizontal plane; then, through Adjust the supporting plane of the fixing medium 1 to realize the fit between the supporting plane and the laying plane of several cables 2 to fix the cables 2, so as to avoid the large bending and uneven force of the cables 2; among them, the cables 2 are suspended in the air Cables in the transition area, the transition area refers to the turning area at the junction of the cable shaft and the cable tunnel; ...

Embodiment 2

[0050] The difference between the first embodiment and the second embodiment is that the fixed medium can be a fixed medium with a polygonal cross-section such as a triangle, a pentagon or a hexagon, and other structures of this embodiment are consistent with the first embodiment.

[0051] In this embodiment, according to the construction requirements, the situation requirements of the turning joints of the cable shaft and the cable tunnel, and the cable laying situation, etc., the fixed medium can be set to have a polygonal cross section, by having at least three supporting planes and being arranged in the transition area. The cables are matched and fitted, and cable clamps are used to fix the cables, thereby improving construction efficiency and quality, and reducing construction costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com