Preshrinking machine with Modbus frequency conversion speed regulation system

A technology of variable frequency speed regulation and variable frequency speed governor, which is applied in the control system, AC motor control, electrical components, etc., can solve the problems of inconvenient control, scattered location, limited application scope, etc., and achieves a high degree of automation, simple wiring, and maintenance. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0018] The specific implementation is as follows:

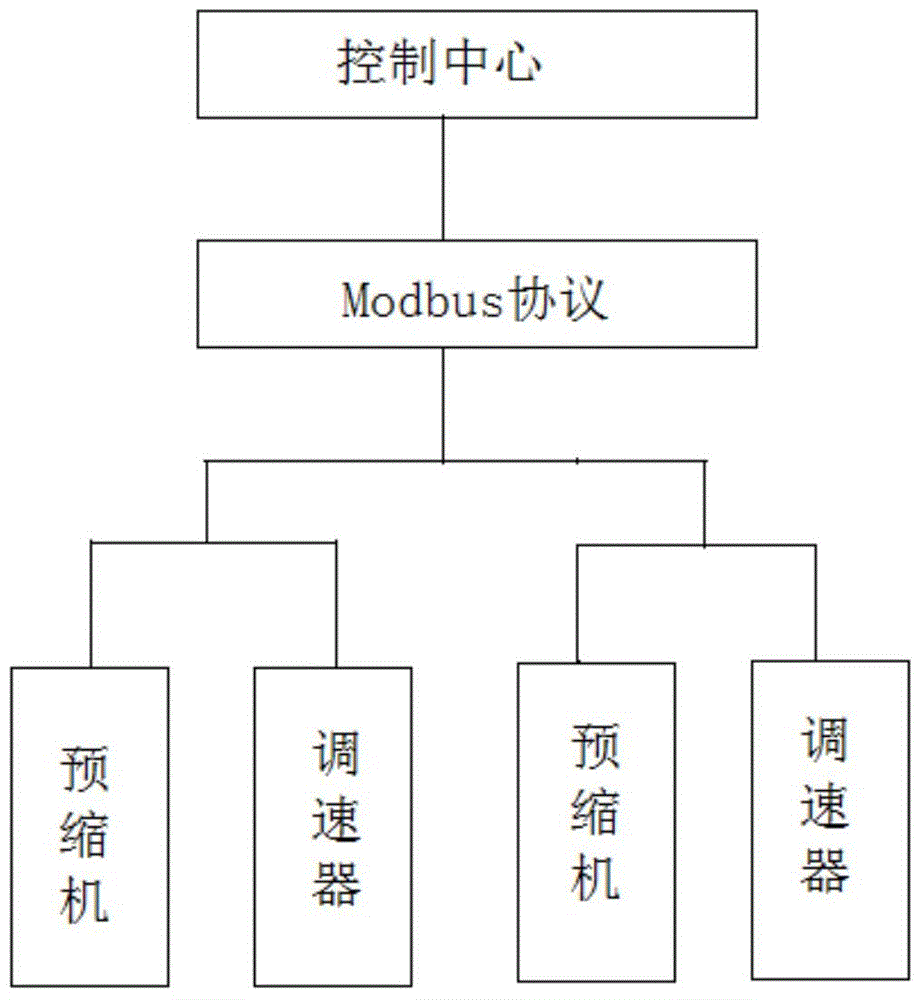

[0019] like figure 1 As shown, a pre-shrinking machine with a Modbus frequency conversion speed control system includes a control center and a plurality of pre-shrinking machines connected to it through the Modbus protocol, and each pre-shrinking machine is provided with a frequency conversion speed regulator. The frequency conversion speed regulator includes a detection module, a control module, a human-computer interaction module, a three-phase power supply, a phase-shifting transformer, and a five-level inverter. The three-phase power supply, a phase-shifting transformer, a five-level inverter and a pre-shrink The machines are connected in sequence, and all are connected with the detection module; the detection module, the control module, and the human-computer interaction module are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com