Thermoplastic compositions, methods of manufacture, and articles thereof

A composition and product technology, applied in the field of laser weldable thermoplastic compositions, can solve the problems of reducing the molecular weight of crystalline materials, unstable melt viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

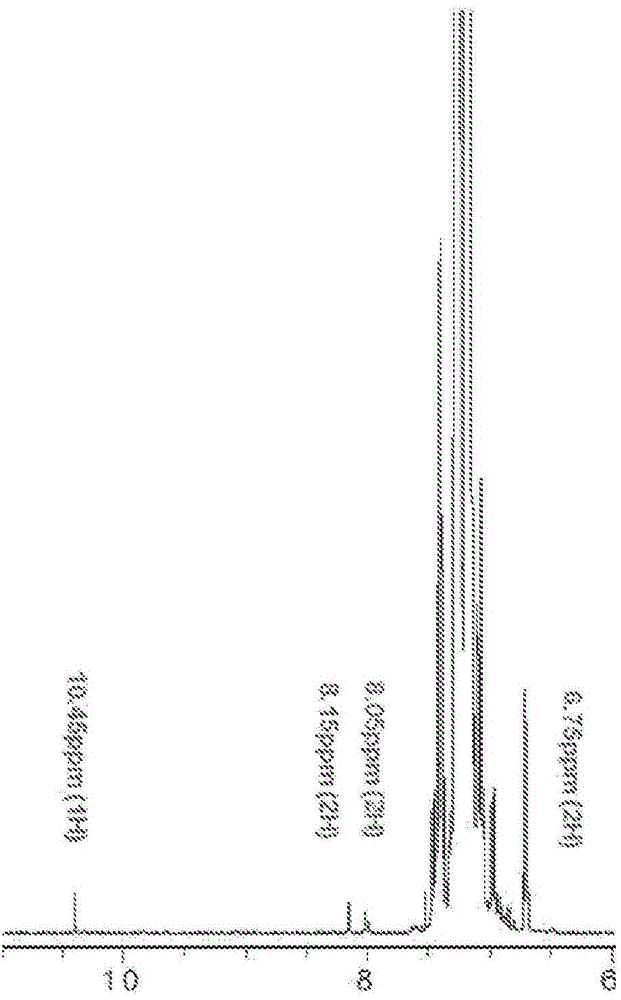

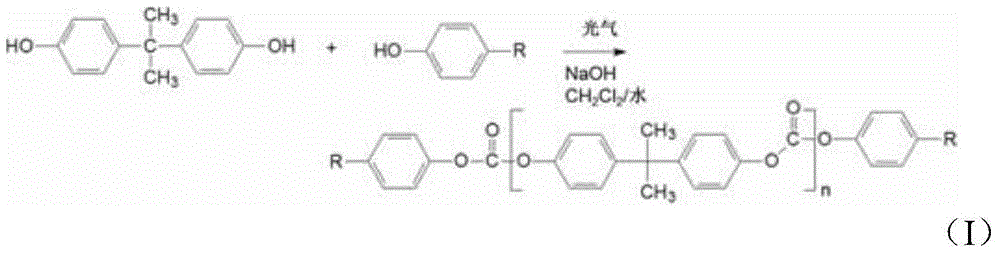

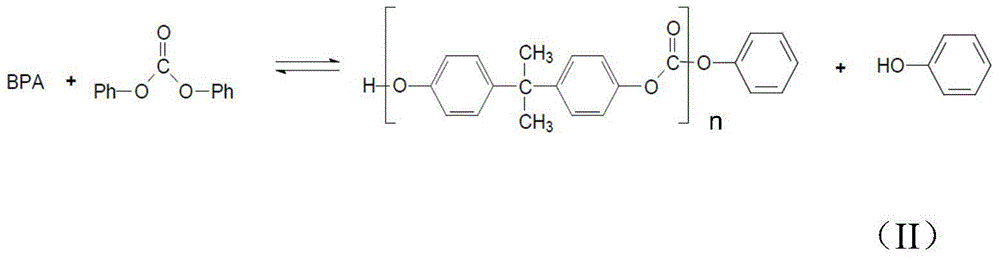

[0071] During the preparation of polycarbonate, the Friesian rearrangement indicated the repeating units present in the polycarbonate with the following formula:

[0072]

[0073] Where R a , R b , P, q, and X a As defined above. R c It can be a hydroxyl group or carbonate or ether. The polymer chain can be formed by carbonate or ether groups. R d It can be hydrogen or substituted aryl groups. The polymer chain can be formed by substituted aryl groups. For example, the following rearrangements can occur (linear fries, branched / ether fries, and acid fries):

[0074] Straight chain fries

[0075] Branched Chain / Ether Fries

[0076] Sour Fries

[0077] During the melt polymerization process, the total amount of branched Friesian rearrangement can be adjusted by changing the temperature and / or the reaction time. This is because the by-products formed at high temperatures include the Friesian rearrangement of carbonate units along the growing polymer chain. The Friesian rearrangeme...

Embodiment approach 1

[0105] Embodiment 1: A composition prepared by a method including melt blending: (a) 10 to 70 weight percent of a partially crystalline polyester component selected from poly(terephthalic acid) Butylene), poly(ethylene terephthalate), poly(butylene terephthalate) copolymer, poly(ethylene terephthalate) copolymer, and combinations thereof; (b) 10 to 60 weight percent of an amorphous polycarbonate, the amorphous polycarbonate having a Friesian rearrangement greater than 150 to 10,000 ppm; (c) 5 to 50 weight percent of filler; and (d) optionally, 0.01 to 10 wt% of antioxidants, mold release agents, colorants, stabilizers, or combinations thereof; wherein the melt blend composition has a polycarbonate aryl hydroxyl end group content of at least 300 ppm; and wherein, when molded When forming a product with a thickness of 2.0 mm, the composition provides a near-infrared transmission greater than 45% at 960 nanometers.

Embodiment approach 2

[0106] Embodiment 2: The composition according to Embodiment 1, wherein, when molded into an article having a thickness of 2.0 mm, based on the average value of samples molded at 70°C and 90°C, the composition provides greater than 48% near infrared transmission.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com