A kind of styrene cross-linked polymer particles loaded with fat-soluble sunscreen and preparation method thereof

A technology of cross-linked polymers and sunscreens, which is applied in pharmaceutical formulations, cosmetic preparations, toiletry preparations, etc., to achieve high embedding rate, reduce absorption and irritation, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

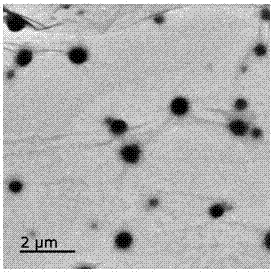

Image

Examples

Embodiment 1

[0040] A styrene crosslinked polymer microparticle loaded with a fat-soluble sunscreen, the raw materials used in the preparation process are calculated in parts by weight, and the composition and content of the raw materials are as follows:

[0041] Surfactant 20.0 parts

[0042] 65 parts of deionized water

[0043] 3 parts fat-soluble sunscreen

[0044] 6 parts styrene

[0045] 0.6 parts of divinylbenzene

[0046] 0.81 parts of initiator;

[0047] Described tensio-active agent is anionic surfactant sodium lauryl sulfate;

[0048] Described fat-soluble sunscreen is ethylhexyl salicylate;

[0049] The initiator is a water-soluble initiator, and the water-soluble initiator is a redox initiation system mixed with potassium persulfate and sodium bisulfite, calculated by mass ratio, wherein potassium persulfate: hydrogen sulfite Sodium is 4:3;

[0050] The concrete steps of its preparation process are as follows:

[0051] (1) First, dissolve 20.0g of surfactant in 65g of d...

Embodiment 2

[0057]A styrene crosslinked polymer microparticle loaded with a fat-soluble sunscreen, the raw materials used in the preparation process are calculated in parts by weight, and the composition and content of the raw materials are as follows:

[0058] Surfactant 12.5 parts

[0059] 65 parts of deionized water

[0060] 3 parts fat-soluble sunscreen

[0061] 6 parts styrene

[0062] 0.6 parts of divinylbenzene

[0063] 0.81 parts of initiator;

[0064] Described tensio-active agent is anionic surfactant sodium lauryl sulfate;

[0065] Described fat-soluble sunscreen is ethylhexyl salicylate;

[0066] The initiator is a water-soluble initiator, and the water-soluble initiator is a redox initiation system mixed with potassium persulfate and sodium bisulfite, calculated by mass ratio, wherein potassium persulfate: hydrogen sulfite Sodium is 4:3;

[0067] The concrete steps of its preparation process are as follows:

[0068] (1) First, dissolve 12.5g of surfactant in 65g of de...

Embodiment 3

[0074] A styrene crosslinked polymer microparticle loaded with a fat-soluble sunscreen, the raw materials used in the preparation process are calculated in parts by weight, and the composition and content of the raw materials are as follows:

[0075] Surfactant 20.0 parts

[0076] 65 parts of deionized water

[0077] 3 parts fat-soluble sunscreen

[0078] 6 parts styrene

[0079] 0.6 parts of divinylbenzene

[0080] 0.81 parts of initiator;

[0081] Described tensio-active agent is anionic surfactant sodium lauryl sulfate;

[0082] Described fat-soluble sunscreen is ethylhexyl salicylate;

[0083] The initiator is a water-soluble initiator, and the water-soluble initiator is a redox initiation system mixed with potassium persulfate and sodium bisulfite, calculated by mass ratio, wherein potassium persulfate: hydrogen sulfite Sodium is 4:3;

[0084] The concrete steps of its preparation process are as follows:

[0085] (1) First, dissolve 20.0g of surfactant in 65g of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com