Preparation method of filter element

A manufacturing method and filter technology, applied in chemical instruments and methods, separation methods, fixed filter element filters, etc., can solve problems such as affecting the assembly of valve core and valve seat, easy deformation of valve seat, affecting the filtering effect of filter element, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

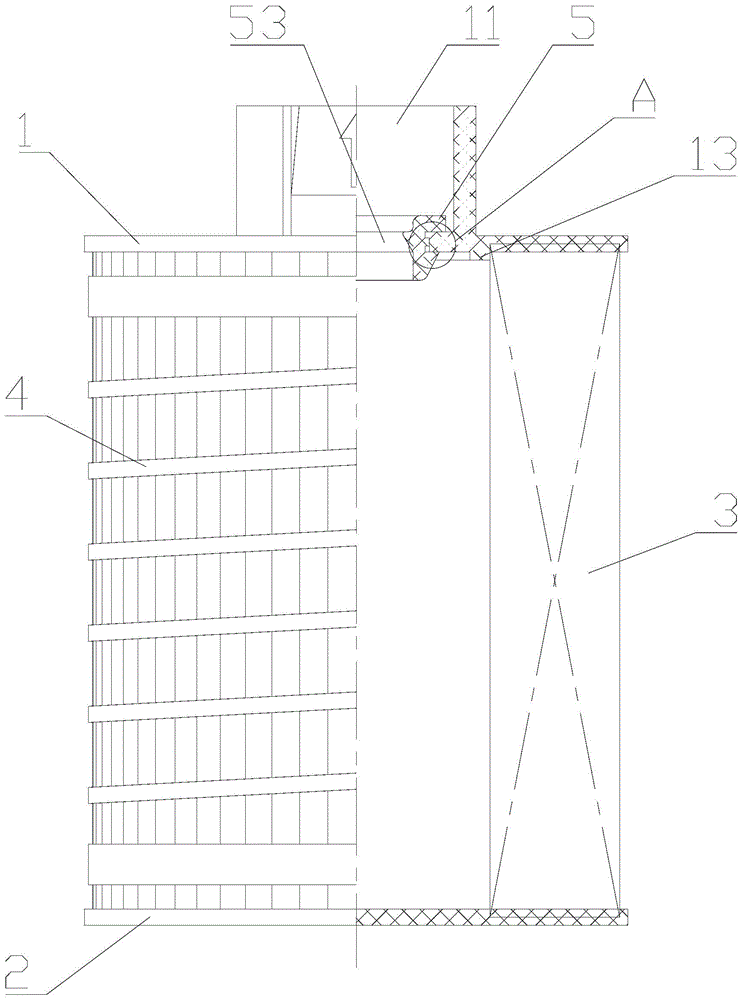

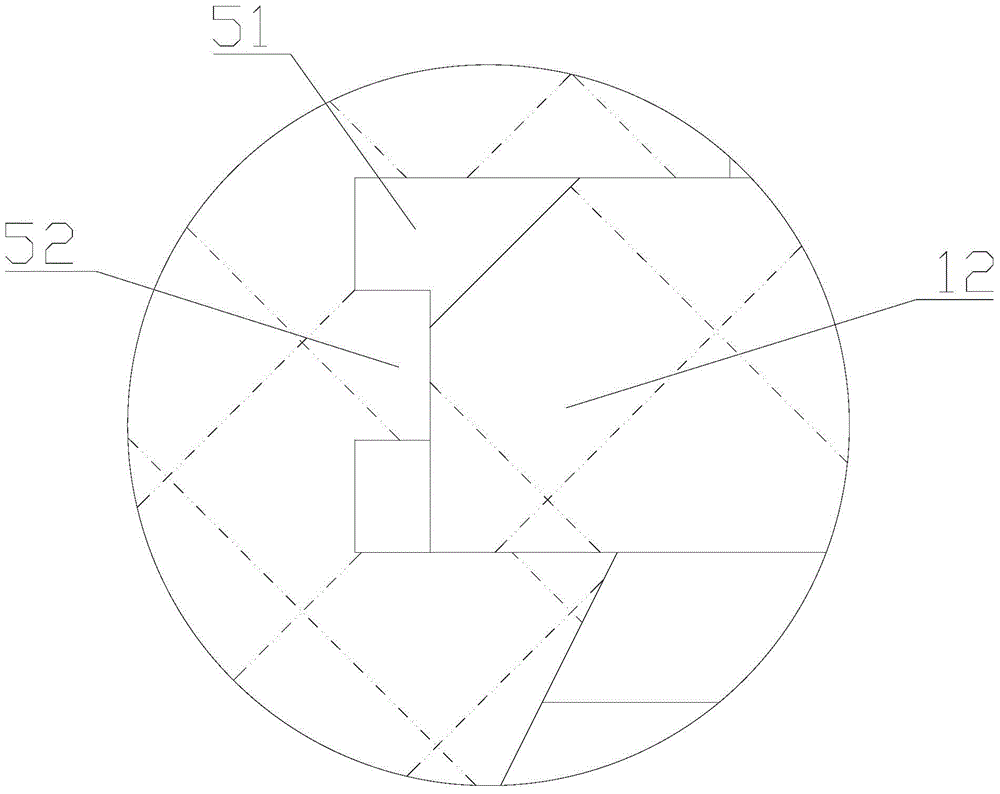

[0014] Such as figure 1 with figure 2 As shown, a method for making a filter element, the filter element includes an upper end cover 1, a lower end cover 2, a paper core 3 and a valve seat 5, and the upper end cover is provided with a first through hole 11, so The valve seat is provided with a second through hole 53 for positioning the valve core, the valve seat is installed in the first through hole of the upper end cover, and the inner side wall of the upper end cover is provided with a radially inward protruding card. Convex 12, the outer wall of the valve seat is provided with a card groove 51 that is engaged with the card convex, the upper end surface of the card convex and the inner wall of the card convex are transitioned through a slope, and the valve seat is located below the card groove The outer wall of the valve seat is inclined and the outer diameter of the lower end surface of the valve seat is smaller than the inner diameter of the card protrusion. The slope o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com