Corncob modified material and preparation method and application thereof

A technology of modified materials and corncobs, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., to achieve strong selectivity and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of corn cob modified material

[0032] S1: After removing the surface dirt from the corncobs, vacuum-dry them at 60°C for 24 hours until constant weight, take them out, pulverize them, and sieve them to obtain dry corncob powder with a particle size of 90 mesh.

[0033] S2: Weigh 10g of corn cob powder into a beaker, add 100mL (0.5mol / L) NaOH solution, soak at room temperature for 24h, then vacuum filter and wash with deionized water repeatedly until the filtrate is neutral, then drain Obtain filter residue. Then add the obtained filter residue into 100mL (0.5mol / L) HNO3 solution, soak again at room temperature for 24h, vacuum filter and wash with deionized water repeatedly until the filtrate is neutral, then pump dry again and dry to constant weight Obtain pretreated corncob flour.

[0034] S3: Take 1 g of pretreated corncob powder into a three-neck flask, add 50 mL of deionized water and soak until all the corncob powder settles to the bottom of the ...

Embodiment 2~5

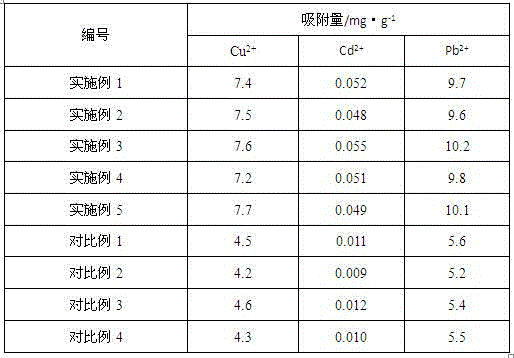

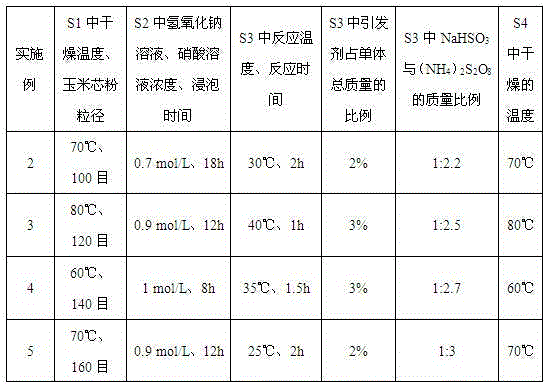

[0045] The main steps of Examples 2-5 are the same as those of Example 1, the difference lies in the process conditions of steps S1-S4, the specific parameters are shown in Table 1, and the experimental results are included in Table 3.

[0046] Table 1

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap