Automatic separating device for fine-sized slime in tailings conveying manifolds

An automatic separation and fine-grained technology, which is applied to fine-grained grading treatment devices and coarse fields, can solve the problems of endangering the personal and property safety of downstream residents, poor safety and stability of tailings dam body, and inconsistent composition of tailings in storage. Reasonable and other issues, to achieve the effect of improving the tailings gradation in storage, reducing the tailings storage, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with embodiment.

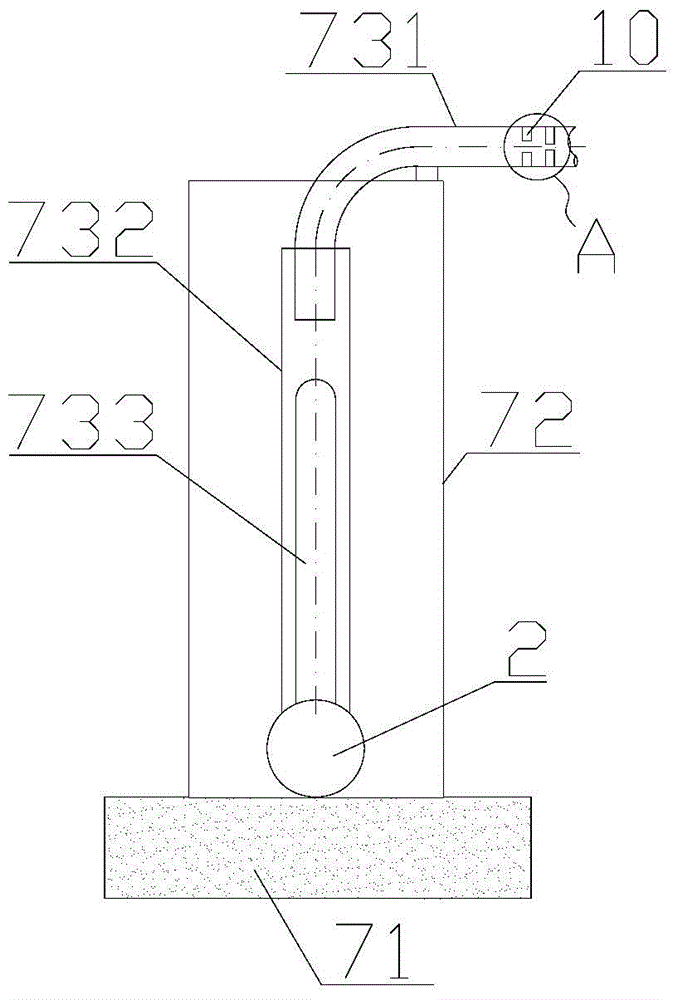

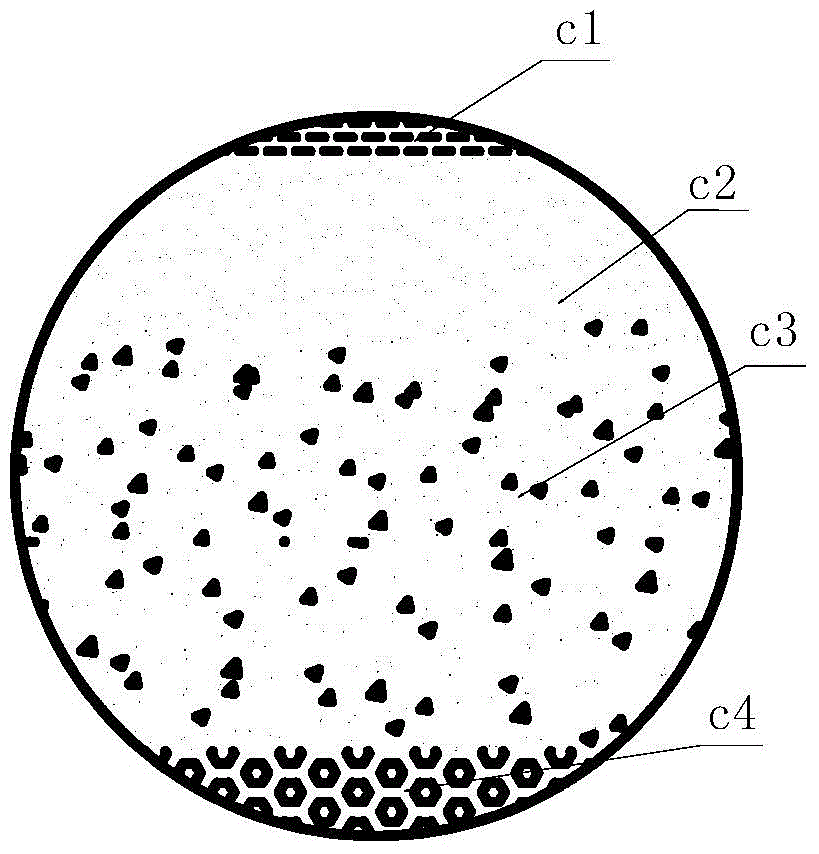

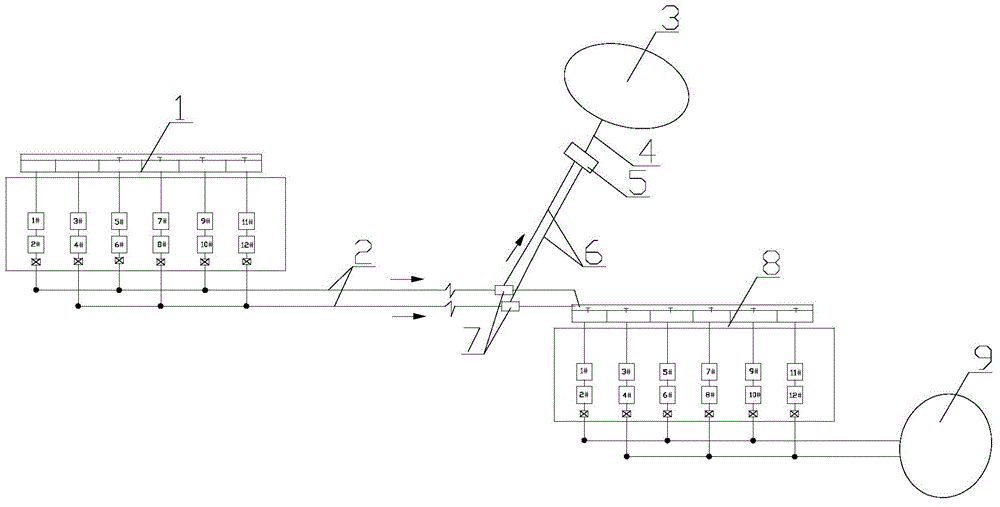

[0017] see Figures 1 to 5 , the fine-grained sludge automatic separation device in the tailings conveying main pipe, including the first-level total sand pumping station 1, the second-level total sand pumping station 8, the tailings pond 9 and the mine pit 3, and the adjacent two-stage total sand pumping station It is connected by a production tailing main pipe 2 and a spare tailing main pipe. The output pipe of the final total sand pumping station is connected with the tailings pond. On the tailing main pipe, there is a door-shaped bracket 72 and a lead-out pipe. The lead-out mechanism 7 composed of the pipe 73 is fixed on the door-shaped bracket, and the lead-out pipe is respectively connected with the tail main pipe and the fine grain conveying pipe 6, and a proportional flow limiting mechanism 10 is set in the horizontal section of the tail of the lead-out pipe; fine grain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com