Full-automatic device for machining inner and outer peripheries of reversers

A processing device and fully automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as high labor intensity, difficulty in meeting the standard requirements of the commutator, and many commutator waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

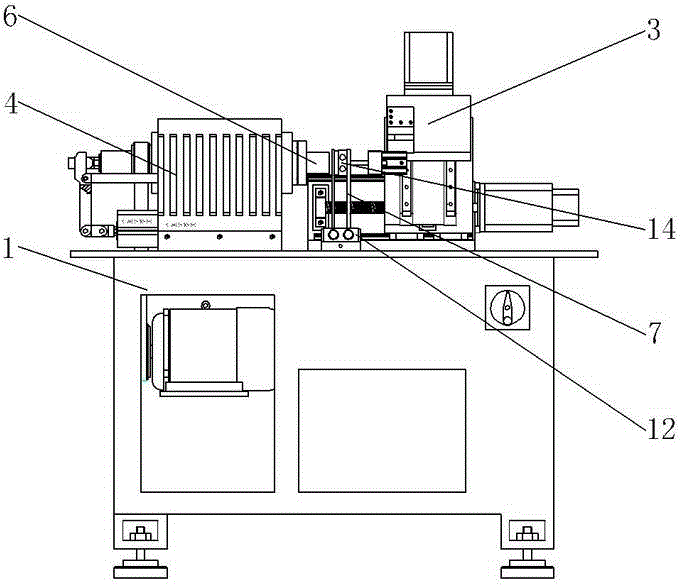

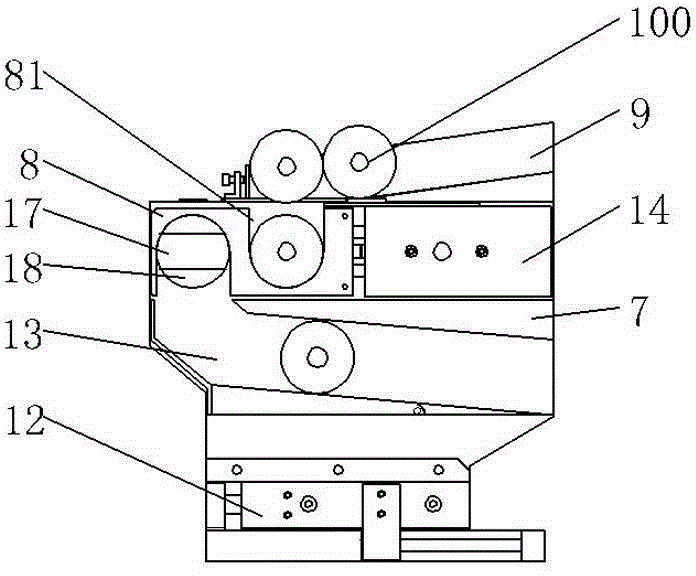

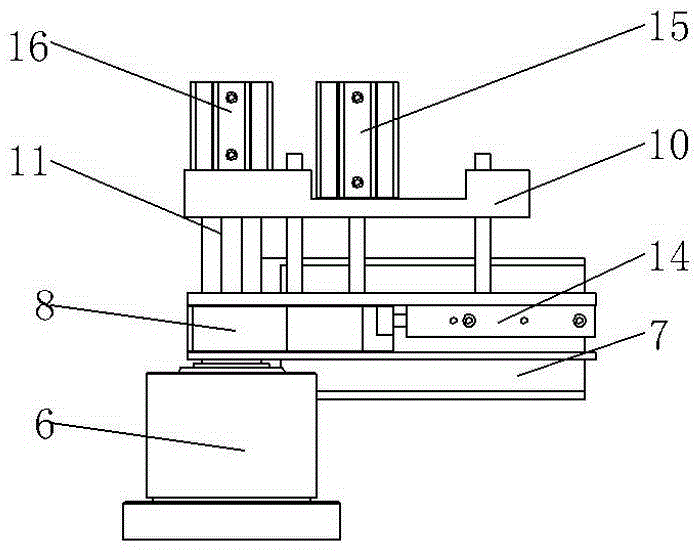

[0016] 1. If figure 1 , 2 , 3, and 4, a kind of commutator automatic inner and outer circle processing device provided by the present invention includes a workbench 1, a conveyor belt 2, a turning tool rest 3, a spindle box 4 and a feeding mechanism 5, and the The turning tool rest 3 is movably connected to the workbench 1, the spindle box 4 is provided with a rotary chuck 6, and the receiving and feeding mechanism 5 includes a limit seat 7, a feeding block 8, a feeding slideway 9, and a pushing plate 10 and the receiving rod 11, the receiving rod 11 is coaxially arranged with the rotary chuck 6, the bottom of the limit seat 7 is provided with a second cylinder 12, and the piston rod of the second cylinder 12 is connected to the workbench 1, and the The limit seat 7 is provided with a discharge slideway 13, and the entire conveying block 8 is in an "S" shape, and the conveying block 8 is arranged in the limit seat 7, and a first A cylinder 14 , the piston rod of the first cy...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap