2M cable soldering device

A welding device and wire bus technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of low welding efficiency, unstable welding quality, scalding and manual injury accidents, etc., to achieve accurate welding points and improve welding efficiency. , The effect of improving welding accuracy and welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

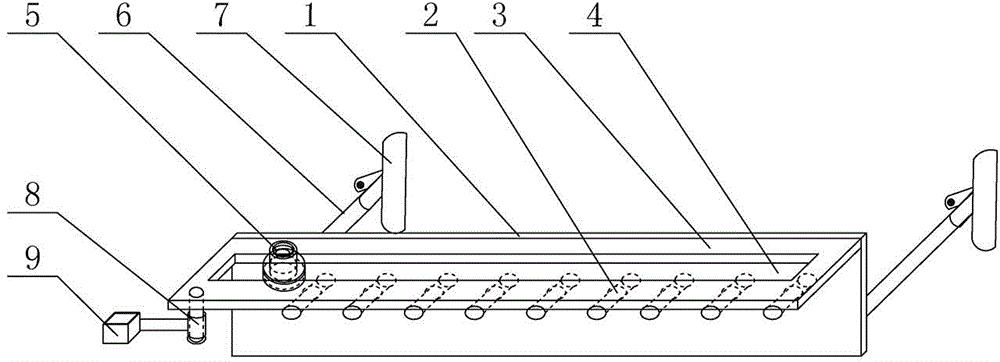

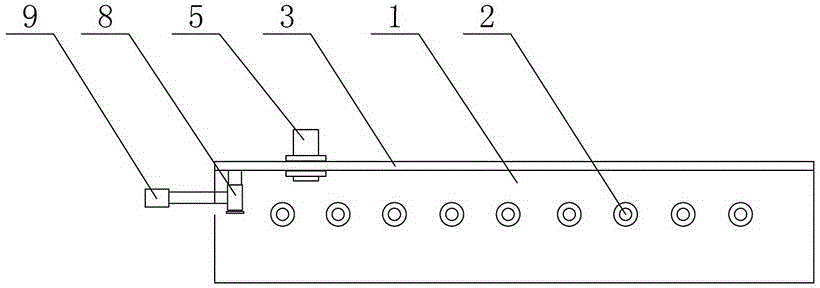

[0031] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 7 As shown, a welding device for welding 2M wires includes a vertically arranged rectangular plate-shaped mounting plate 1, and the front vertical mounting plate 1 of the mounting plate 1 is provided with a group of 2M line female heads 2, 2M line female heads 2 Arranged at equal intervals, and the arrangement direction of the 2M line female headers 2 is consistent with the extension direction of the long side of the installation plate 1; the front of the installation plate 1 is vertical to the installation plate 1. The first supporting plate 3 is provided with a rectangular plate. shape, the first supporting plate 3 is located above the 2M line female head 2, the first supporting plate 3 is set horizontally, and a slideway 4 is arranged on the first supporting plate 3, the slideway 4 is in the shape of a rectangular strip, and the direction of the slideway 4 Consistent with the extension direction of the lon...

Embodiment 2

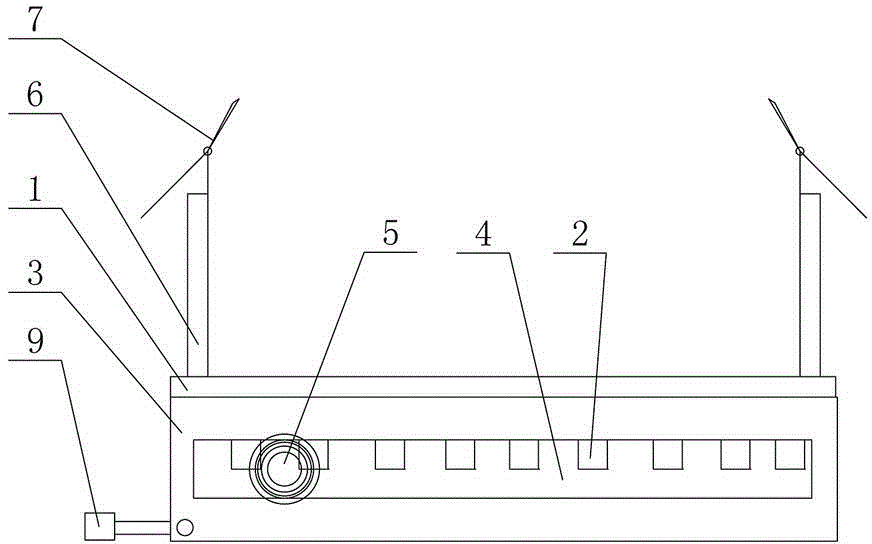

[0033] Embodiment 2: as Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a welding device for welding 2M wires includes a vertically arranged rectangular plate-shaped mounting plate 1, and the front vertical mounting plate 1 of the mounting plate 1 is provided with a group of 2M line female heads 2, 2M line female heads 2 Arranged at equal intervals, and the arrangement direction of the 2M line female headers 2 is consistent with the extension direction of the long side of the installation plate 1; the front of the installation plate 1 is vertical to the installation plate 1. The first supporting plate 3 is provided with a rectangular plate. shape, the first supporting plate 3 is located above the 2M line female head 2, the first supporting plate 3 is set horizontally, and a slideway 4 is arranged on the first supporting plate 3, the slideway 4 is in the shape of a rectangular strip, and the direction of the slideway 4 Consistent with the extension direction of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com