Microhole precision-machining method based on dielectrophoresis

A technology of precision machining and tiny holes, applied in the field of precision machining, can solve the problem of not being able to take into account high precision, high efficiency and high consistency at the same time, and achieve the effect of increasing the residence time and the number of abrasive particles, and improving the machining efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

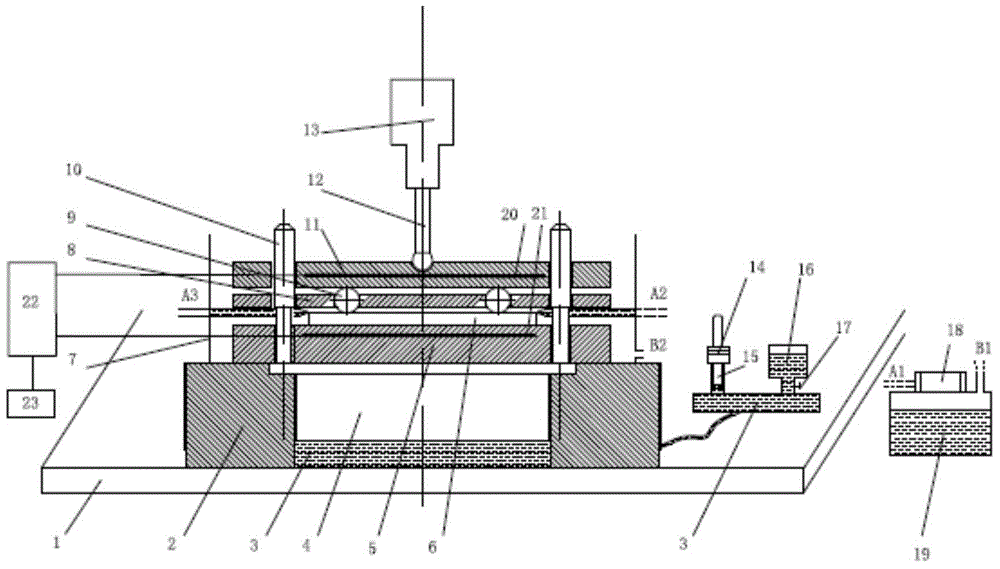

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

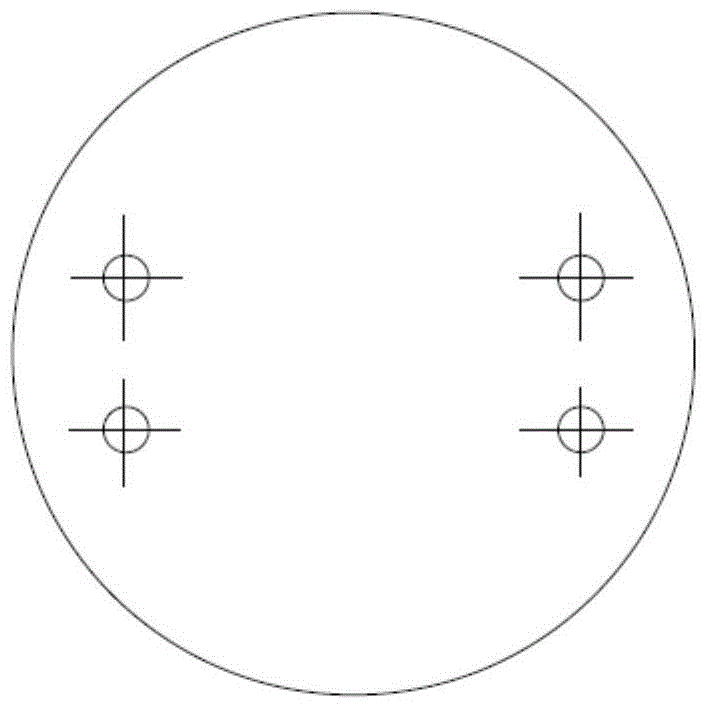

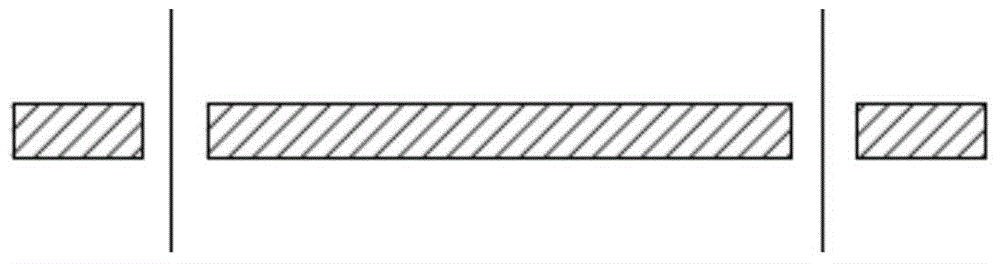

[0029] refer to figure 1 ~Fig. 4, a kind of micro-hole precision machining method based on dielectrophoretic effect, the device that realizes this method comprises exciter 13, and described exciter 13 is installed with luffing vibrating rod 12, and described luffing vibrating rod The end of 12 is spherical, and it is pressed on the working pressure plate 11. The said working pressure plate 11 presses the hole-shaped impact piece 9, and the hole-shaped impact piece 9 is placed in the hole-shaped impact piece holder 8 holes. The impact member holder 8 is positioned by a positioning cylindrical pin 10, and the positioning cylindrical pin 10 is installed on the workbench 2. Below the hole-shaped impact member 9 is the workpiece 6 to be processed, and the workpiece 6 is placed on the reference worktable 5 Above, the reference worktable 5 is installed on the hydraulic pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com