Back-row seat framework made of hybrid materials for passenger car

A rear seat and mixed material technology, applied in the field of auto parts, can solve problems such as increased production costs, automobile exhaust emissions, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

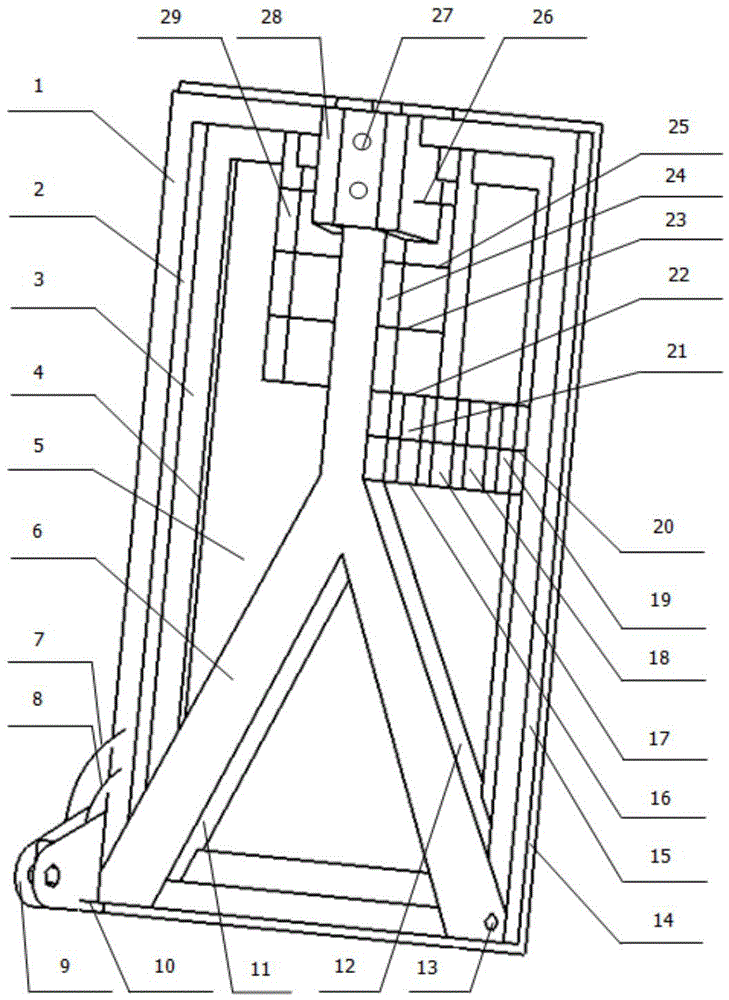

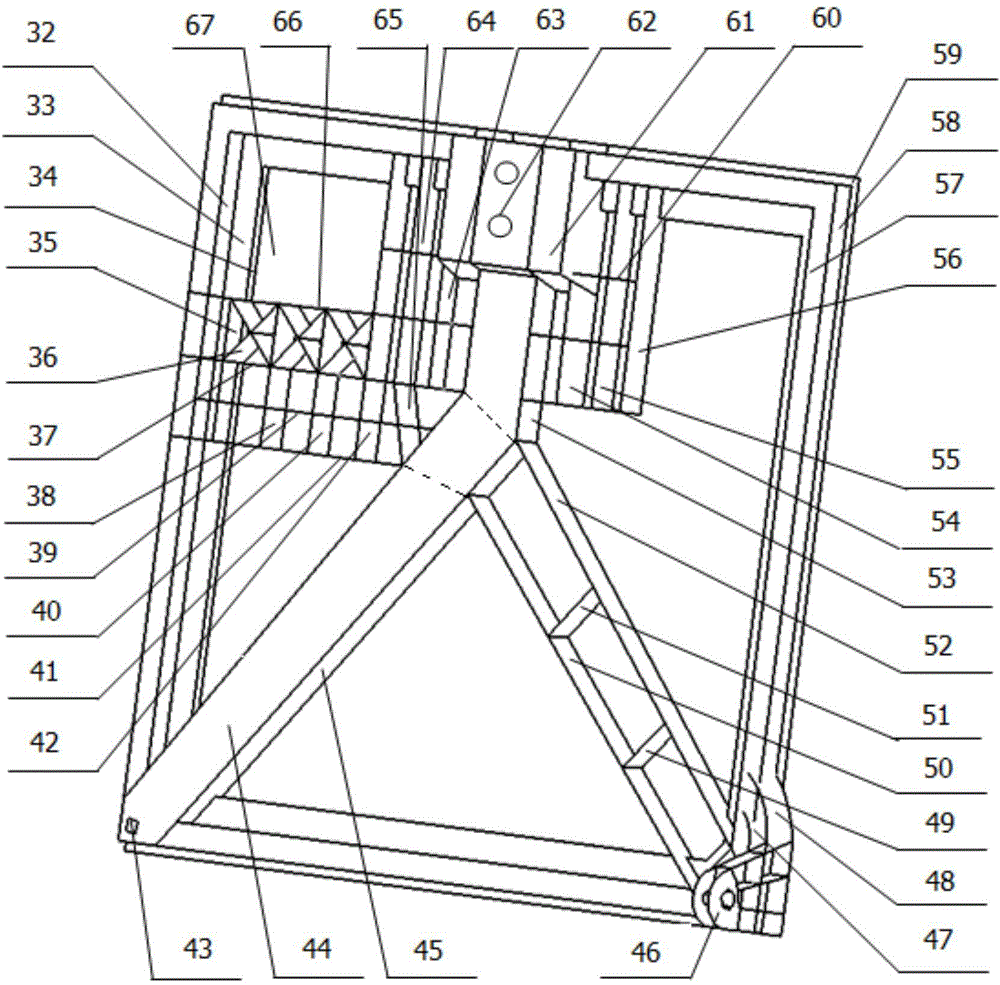

[0051] The present invention is described in detail below in conjunction with accompanying drawing:

[0052] refer to Figure 4 and Figure 5-a , the rear seat frame of the hybrid material passenger car in the present invention is a split structure, that is, the rear seat frame of the hybrid material passenger car in the present invention is composed of the No. 1 seat frame and the No. 2 seat frame Composition; No. 1 seat frame and No. 2 seat frame are installed side by side on No. 1 trolley part 69, No. 2 trolley part 72 and No. 3 trolley part 73 on the passenger car, more precisely, 1 The No. 2 seat frame and the No. 2 seat frame are fixedly connected to the No. 1 ground hinge 68, the middle ground hinge 71, and the No. 2 ground hinge 74 of the passenger car by using bolts side by side. In the embodiment, the No. 1 seat frame The horizontal distance from the No. 2 seat frame is 32mm.

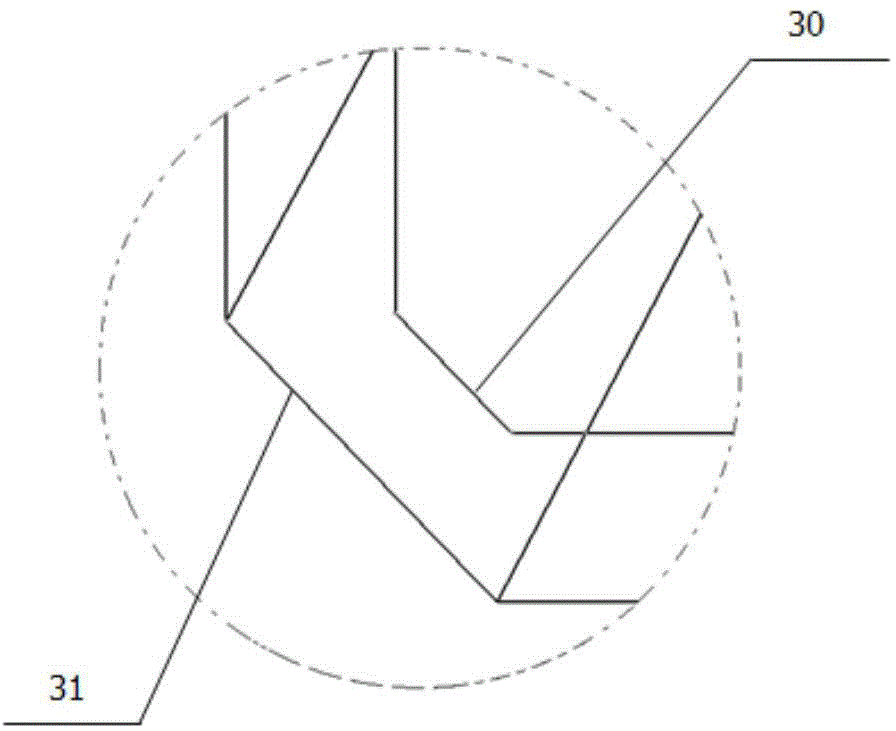

[0053] refer to figure 1 and image 3 , the No. 1 seat frame and the No. 2 seat frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com