Crash- and pressure-proof packing case

A packaging box and anti-pressure technology, which is applied in packaging, packaging food, transportation and packaging, etc., can solve the problems of poor load-bearing capacity of the packaging box, easily damaged items in the box, and no pressure resistance, and achieve a good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

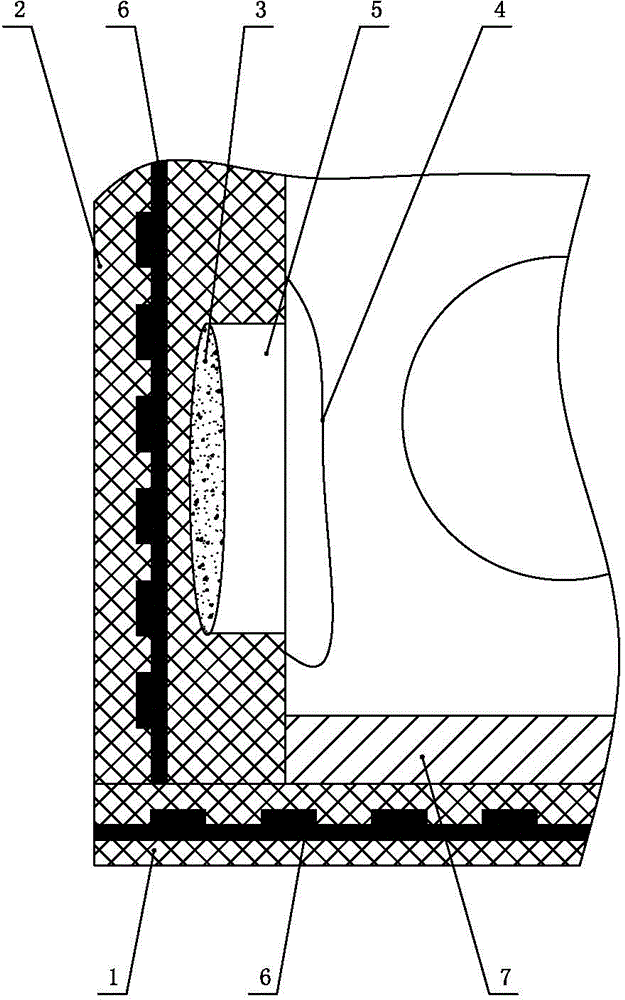

[0014] Such as figure 1 Shown is a partial structure schematic diagram of the present invention. The anti-collision and anti-pressure packaging box includes a box body, and the box body is surrounded by an upper cover plate, a lower bottom plate 1 and four side walls 2 . The inner surfaces of the lower bottom plate 1 and the upper cover plate are respectively provided with elastic buffer pads 7 to avoid bumping and bumping up and down of the items in the box.

[0015] The inside of the side wall 2 is provided with a cavity, and a film bag is provided in the cavity, and ammonium nitrate 3 is filled in the film bag; the inner surface of the box body is provided with a through hole 5 communicatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com