A method for preparing copper-based nano-zinc oxide-polyvinylidene fluoride composite material

A technology of polyvinylidene fluoride and nano-zinc oxide, which is applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as unfavorable unified production standards and industrial application, complex preparation process, etc., and achieve innovative and easy preparation methods , raw materials are cheap and easy to obtain, and the operation is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing copper-based nano zinc oxide-polyvinylidene fluoride composite material, comprising the following steps:

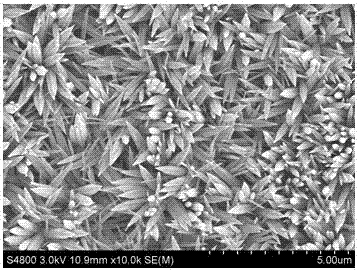

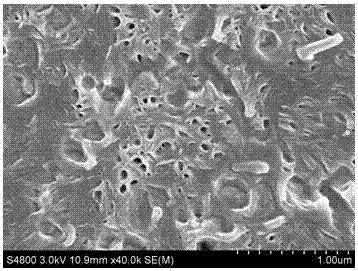

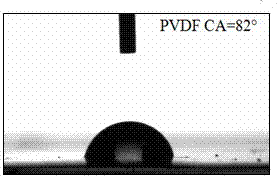

[0023] 1) Cut a 4cm×4cm copper sheet as the base material, polish the copper sheet with 800 mesh, 1500 mesh, and 3000 mesh in turn to make the surface rough, and then ultrasonicate it in acetone, absolute ethanol, and ultrapure aqueous solution for 5 minutes, and take it out. After blowing dry with nitrogen, place it in an oven at 60°C for 1 hour to oxidize to seed the copper-based surface; prepare a chemical bath solution, select c(Zn 2+ ) : c(OH + ) = molar ratio of 1:8, Zn 2+ is derived from zinc nitrate hexahydrate [Zn(NO 3 ) 2 6H 2 O], OH + The source of sodium hydroxide NaOH, respectively measure 25mL solution in a 40mm × 70mL weighing bottle, mix and stir until clear to form a chemical bath solution, hang the copper piece in the chemical bath solution in reverse, and place it in a hot water bath at 60°C Zinc oxide nano-cone film ...

Embodiment 2

[0028] A method for preparing copper-based nano-zinc oxide-polyvinylidene fluoride composite material, comprising the following steps:

[0029] 1) Cut a 4cm×4cm copper sheet as the base material, polish the copper sheet with 800 mesh, 1500 mesh, and 3000 mesh in turn to make the surface rough, and then ultrasonicate it in acetone, absolute ethanol, and ultrapure aqueous solution for 5 minutes, and take it out. Blow dry with nitrogen and oxidize in an oven at 60°C for 1 hour to seed the copper-based surface; prepare a chemical bath solution, select c(Zn 2+ ) : c(OH + ) = molar ratio of 1:8, Zn 2+ is derived from zinc nitrate hexahydrate [Zn(NO 3 ) 2 6H 2 O], OH + The source of sodium hydroxide NaOH, respectively measure 25mL solution in a 40mm × 70mL weighing bottle, mix and stir until clear to form a chemical bath solution, hang the copper sheet in the chemical bath solution in reverse, and place it in a 70°C hot water bath Zinc oxide nanocone film was prepared by chemic...

Embodiment 3

[0034] A method for preparing copper-based nano-zinc oxide-polyvinylidene fluoride composite material, comprising the following steps:

[0035] 1) Cut a 4cm×4cm copper sheet as the base material, polish the copper sheet with 800 mesh, 1500 mesh, and 3000 mesh in turn to make the surface rough, and then ultrasonicate it in acetone, absolute ethanol, and ultrapure aqueous solution for 5 minutes, and take out nitrogen After drying, place it in an oven at 60°C for 1 hour to oxidize the copper-based surface; prepare a chemical bath solution, select c(Zn 2+ ) : c(OH + ) = molar ratio of 1:8, Zn 2+ is derived from zinc nitrate hexahydrate [Zn(NO3 ) 2 6H 2 O], OH + The source of sodium hydroxide NaOH, respectively measure 25mL solution in a 40mm × 70mL weighing bottle, mix and stir until clarified to form a chemical bath solution, hang the copper piece in the chemical bath solution in reverse, and place it in a hot water bath at 80°C Zinc oxide nanocone film was prepared by chemi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com